-

Posts

152 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Teradee

-

i hadnt considered that for some reason! thanks for the recommendation!

-

Im using pretty heavy thread....bonded nylon, size 138. I think the need is a 20 or 22? i do all of these often as well, but i havent tried leaving it long and hand back stitching. that might be nice as back stitching often looks a little messy

-

Hi everyone! I’ve been saddle stitching a while and it works great and importantly it rarely budges once finished. I’ve recently started machine sewing and my question is this…I normally add a lock stitch to beginning and end, I sometimes groove for the stitches to sit down in, and hammer it when done. With all of that, it still seems like it’s on the verge of coming apart. Are there additional ways to really lock that stitch line down? CA glue? Something else help?? thanks for any tips! Jason

-

I think I will post a short video and show you the parts im referring to, and how it all performs. There's not much to these, but for some reason I'm not seeing where its binding. More to come!

-

I am currently looking for a sewing guide that would fit that model machineHello all, I’ve been looking and found a few places that have the basic parts for a brother, LS2 – B837. I am currently looking for a sewing guide that would fit that model machine. Does anyone know of a guide that would fit that machine or are there generic options that I should be looking at? Also, I just purchased some Vinymo mbt thread in size 1, 5, and 8. Would anyone know in this group whether or not this brother machine would so with number one or number 5 thread? I am told number five thread for this supplier is similar to 138. Thanks again, everyone!

-

Yes, I oiled those points and there is a little play back-and-forth with the shaft. It definitely feels a little sloppy. Is there a way to tighten up the shaft or the function of that mechanism? By the way, thanks again for all the help and advice everyone! This forum is incredibly helpful to people like myself who are just getting started in this work!

-

Update: I noticed with the shuttle out, the binding doesn’t occur. With the shuttle in, it gets “stuck” at one point in the cycle and binds. Do I need a new shuttle? (It looks fine…no sharp or rough edges, etc). Or is this something else perhaps?

-

Thanks @Wizcrafts and @Constabulary! I will try your suggestions right away! (by the way, I wasn’t sure I could use a heavier oil in these machines…I was always warned to only us sewing machine oil. That said, when I opened the window in the rear and look at the cam and where it connects to the shaft that rotates the shuttle, it’s coated in a very thick grease of some kind. And when I tighten the large screw below that window, it just spins and spins. That might be a culprit as well I’m guessing. )

-

Hi all! I just became the proud owner of a 29-4. As I was oiling and beginning the cleaning process, I threaded it up and tried to sew with it. Anyway, every time I move the wheel and the needle is about to pierce the leather, it sounds like the internals are bumping together and the needle “bounces”, but never touches the leather. It’s gotta be something inside the machine, but I can normally push things around and at least get the machine to move past the point where it’s binding. anyone have this issue with the 29-4?

-

I have an old machine (Singer 18-3 treadle with cylinder arm and rolling foot/wheel feed). It’s a nice machine and interesting to use. I like to make all kinds of stuff, but wonder if the 18-3 is particularly “special” when making more delicate pieces like wallet interiors, small bags, etc. I will also have a 29-4 (and a cylinder arm), a 31-15, and a 66. Forgetting the price for a minute and solely thinking about the utility…What do you all think? Go ahead and sell the 18-3 and just use these other machines? Or will I miss it? Any advice would be awesome! Jason

-

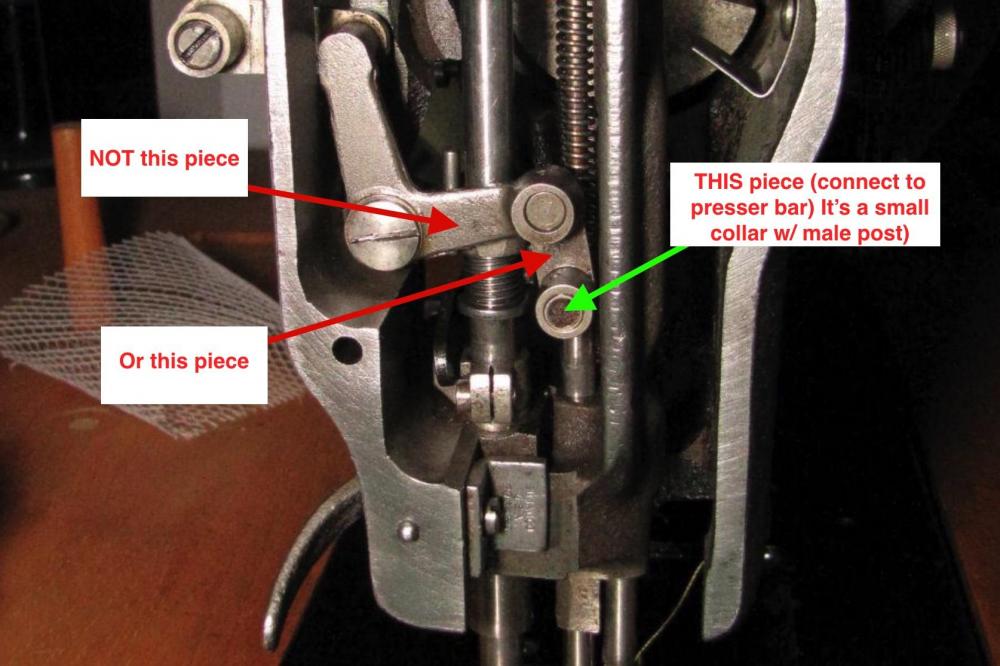

It also looks like I need the following part. Mine is cracked. Is this an easy part to locate? Any idea what its called?

-

Will do. I also saw a thread from a while back stating the need to adjust the eccentric to get it back to the right position? Thanks!

-

Well, I think I may have found the thread to help fix. (related to setting presser height and getting everything synced back up so the bar doesnt bind)

-

Hi there! Im wondering if anyone had some advice. I’d be happy to post pics/video later when I return home. I have a 111w155. I cleaned it up and oiled it up. When back together, the mechanism operates smoothly, including the walking foot…but, the presser foot is super hard to move up/down. And after I use the lifter, it won’t come back down into position on its own. I have to push both feet back down into position. Does anyone have an idea what what might be?? I’ve loosened set screws, oiled it up, etc. The bar holding the presser foot seems to fit the sleeve at the very top really really snug. Let me know if that sounds familiar! :-)

-

I thought I’d post some pictures of a handful of machines that fell in my lap. I definitely don’t need all of these, so I think I’ll post them for sale (once I get my hands on them and can share all the details). Located near Milwaukee Wisconsin. I’m 100% positive I’ll be selling them for less than the going price…(I only need 1 or 2, and have very little money invested, so should be a good deal coming). Let me know if any of these attached machines look interesting, or keep an eye open for my post. I think I’ll end up with the following Singers…. 212, 111W155, 145W304 Long Arm (x2), 68 Bartack(?) These came from a shop closing and were used daily Sewing Machines.pdf Thanks, and thank you WIZ for the help and info! Jason

-

5 machines (fell in my lap, details coming)

Teradee replied to Teradee's topic in Leather Sewing Machines

Oops! Sorry about that. I assumed it was for this channel. I will move it there. -

I thought I’d post some pictures of a handful of machines that fell in my lap. I definitely don’t need all of these, so I think I’ll post them for sale (once I get my hands on them and can share all the details). Located near Milwaukee Wisconsin. I’m 100% positive I’ll be selling them for less than the going price…(I only need 1 or 2, and have very little money invested, so should be a good deal coming). Let me know if any of these attached machines look interesting, or keep an eye open for my post. I think I’ll end up with the following Singers…. 211G, 111W155, 145W304 Long Arm (x2), 68 Bartack These came from a shop closing and were used daily Sewing Machines.pdf Thanks, and thank you WIZ for the help and info! Jason

-

Hi Everyone! Im really interested in skivers…mostly because I struggle doing it well but using knives and hand skivers. do you recommend the manual machines and hand cranks? I know the modern electric ones (eg bell skivers) are awesome but do you recommend considering cost and the types of things being made, etc? or, do you recommend just practicing with a well sharpened knife? thanks for any advice…will be much appreciated! Jason

-

Well, an interesting update. I came across a Techsew 2900 Shoe Patcher for a very low price, so decided to pull the trigger to try it. It was for the head only, so I'm now interested in pairing it with a motor that will make this a machine thats solid to use and easy to operate. Does anyone have any advice on an easy to operate (slow moving), solid motor setup to purchase? ...A big plus if theres a table recommendation as well...! Advice could also include some DIY / lower cost options finding motors on FB, or repurposing tables, etc. I'm open to advice! Thanks! Jason

-

Not sure exactly where to find the right solution so I thought I’d post my sewing machine dilemma and see if you all have strong opinions. I have a few older machines (singer 66, singer 31-15, and a singer 18-3) This is just a hobby for me, but I love using the right tool for the job…but paying too dollar right now is not reasonable for me. so…would you: 1 - pay someone to update one of the machines I own and make it more usable and stable. 2 - put a hand crank on one of these machines or a new servo motor/diy 3 - keep looking for a machine that would be a decent “Jack of all trades” without breaking the bank (and what machines would those be). (Note: I want to see lots of variety to try things out, but tend to like medium to heavy weight “guy” stuff) 4 - go to a dealer and buy something used and if so, what would I be looking for? 5 - swallow hard and buy a modern, fairly expensive new machine (and here are the ones to choose from)? LOTS of options. I never said it would be easy advice! Thanks in advance! Jason

-

Ozaukee Cty. Great info!! Thanks!

-

Hi everyone! I bought an old singer 18-3. I cleaned it up, oiled it up, and it sewed for a few rows and now I can’t figure it out to save my life. it is not catching the bobbin thread now, but when it was, it was not sinching the stich down and the bobbin side was laying flat on the leather with small loops holding it there (I assume the tension?). Im in Wisconsin. Anyone know a way to get that machine to be a solid, less finicky machine? thanks! jason