dans79

Members-

Posts

149 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

dans79's Achievements

Member (2/4)

-

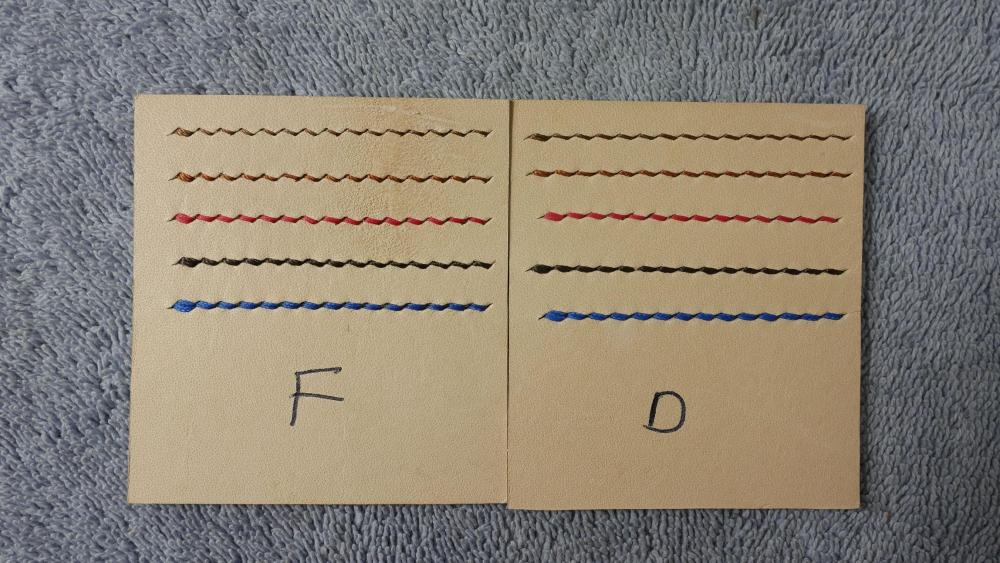

I have the 3.85 mm set, and used them to make the test sample on the left side of this photo. The right test sample was done with the the 4.0 mm diamond set. The thread from top to bottom is : 0.4 to 0.45mm Vinymo MBT #8 0.6mm Vinymo MBT #5 0.6mm tiger thread 0.75mm Vinymo MBT #1 0.8mm tiger thread Please note I'm a complete newbie!

-

keep in mind JJ needles are fairly cheap and made in china! In the past I've wondered if sizes #1 through #3 aren't just quality control binning, because you need meteorology equipment or a good loop to tell the difference. Not to mention i have some #3s that look bigger than #2s. I've thought about picking up some System S+U needles that are made in Germany, as they have a more diverse size range. However they are 2.5 to 3 times more expensive than JJ needles, and seem much harder to find in the states. Here is a photo I found showing the size range of System S+U needles.

-

The eyelet inner and outer sizes are different. That effects how easy it is to get the needle and the thread immediate next to the needle through the leather.

-

Your using a larger needle than you need to, and that's making your life a little harder than it needs to be. 0.8mm will work fine with a #3 needle, and with a little finagling you can even get it to work with a #4. with regards to the Sinabroks, they are wider at the tip than other french style irons if memory serves. French irons should by nature require a little more force as they are flat at the tip while diamonds form a point.

-

It can be worth it, but it needs to be like a 40+ year old hammer, preferably even older if you can find it. My brother has one of my grandfathers hammers from the 1920' or 30's, that is a real jem. Hard enough that it won't mar, but soft enough that it won't chip.

-

Personally I wouldn't risk it, unless you can get your hands on a hammer that you know is 30 to 40+ years old. If you have the tools for forging, you would probably be better off starting with a piece of bar stock of a known grade of steel. God knows what random cheap steel they use to make hammers now.

-

It's a lot easier and faster to do on a hammer, as you don't have to worry about screwing up the edge like you do on a knife or chisel!

-

This is why I haven't purchased anything from Osborne. They charge top tier prices, but what they sell has bottom tier fit and finish. I modified a ball pein to use as a cobblers hammer, maybe the info will help you make the Osborne usable.

-

Yea, manufacturers and retailers have made a real mess by using an inconsistent naming convention.

-

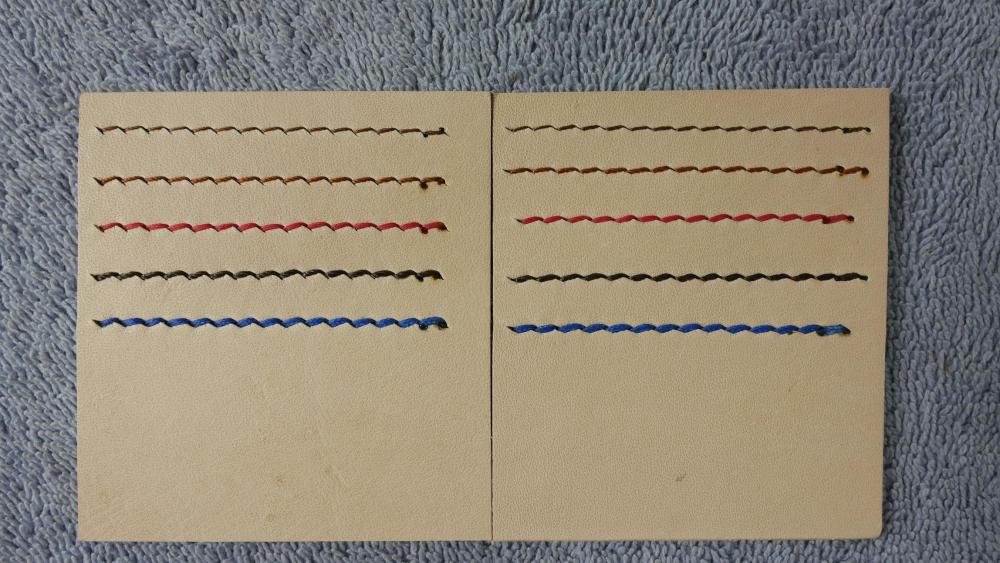

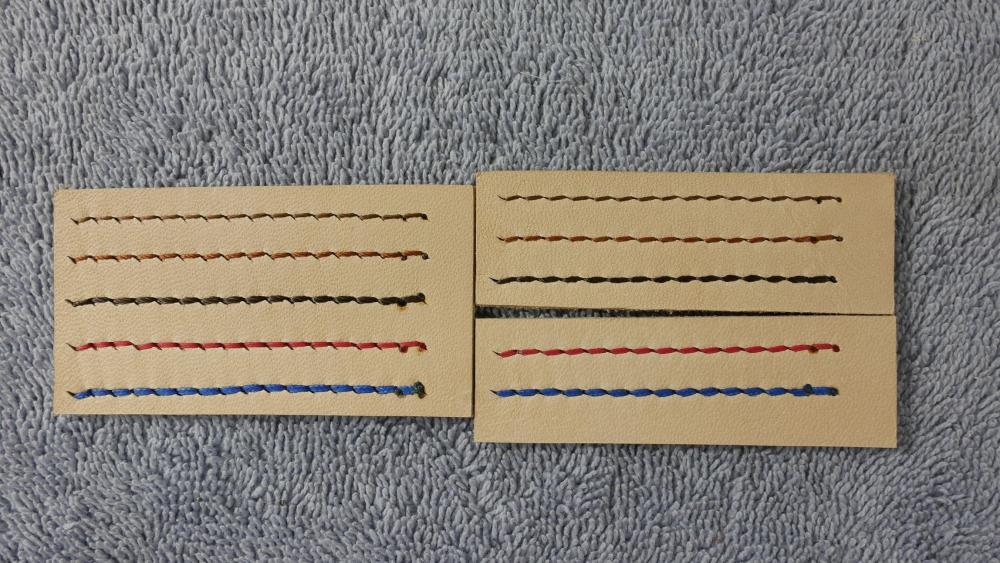

Here you can see a comparison now that I'm doing the cast correctly, thought i still need to get a better handle on the appropriate amount of tension for both types of irons so the stitches look more consistent, but I'm much happier with the results. 2 layers of 2.5oz glued together. The thread from top to bottom is : 0.4 to 0.45mm Vinymo MBT #8 0.6mm Vinymo MBT #5 0.6mm tiger thread 0.75mm Vinymo MBT #1 0.8mm tiger thread Personally I think the french irons look better on the front side up to Vinymo #1. For the diamonds i wouldn't go larger than the 0.6mm tiger thread or Vinymo #5. On the back side the french are much better than what they where yesterday. Are there any tricks to make the back side of the french look better (more centered vertically)? Or maybe a book with good information in it? As an aside, one thing I've noticed is that the tiger thread is a little easier to work with imo. Every now and then the Vinymo will twist itself tighter for a stitch or two and throw of the look of the stich. Front Back

-

Yea I'm doing that, i picked that part up from the Leodis Leather video on saddle stitching. I'm working on some practice pieces right now, and i think I have my issue corrected. However the French irons definitely seem more sensitive than the diamonds to the angle and amount of force you use when tensioning the thread.

-

Take a look at the full resolution photo of the back (right click open in a new window), and you will see that the thread is shifted up on all the french lines, but is centered on the diamond lines. The fronts look the same way to me, just not as extreme. I was casting, but since I posted the photos, I think i might have had one step wrong, and the diamonds are just doing a better job of covering it up. I need to glue up some more practice leather, But i will give it another go this afternoon when I work through what i think i was doing wrong. I think the thing that makes it hard to learn, is that none of the popular personalities showing how to stich, use the same terminology.