Search the Community

Showing results for tags 'jig'.

-

A couple years ago I bought an Al Stohlman Tandy round knife. It wasn't even close to the condition he describes in his 'Use and Care of Hand Tools' - type book, and I only made it much worse trying to sharpen it by hand. So I built a "Thing". I work in the aerospace industry for a living, so I had a pretty good idea of where I wanted to end up, and knew that I would fall far short of that level working in my garage with hand tools. I used a piece of 2" x 2' x 1/4" angle iron, and put a lot of thought and work into it. I used the Lansky sharpening system idea, basically, working up to their finest stone, and quit (for now) with their leather strop. I originally put this idea up on a 'Facebook' page, and took a lot of flack about it not being perfect, or exactly equal throughout the entire curve of the blade, etc, Some of the people commenting were big names in the sharpening business, and they definitely know what they were talking about. The thing that they didn't get was that I just wanted something that would work for my occasional project, and I leave my pursuit of perfection behind at the company's door when I leave my job in aerospace for the day, and go home to work on stuff. I stole my motto in life from Theodore Roosevelt..."Do what you can, with what you have, where you are". I think it turned out great, because now I can cut caiman tails so fine that when you hold the cut edges together, it's hard to see where you caused the separation. (I haven't been on this site in a long time, so I'm not being rude if I don't respond to questions. I don't have any type of instructions, never made a single drawing, or anything like that. The only important thing that I can tell you is that I did my trigonometry calculations to come up with a 15 degree angle on the blade. Like I said, I have an Al Stohlman knife, but you can customize it to whatever you have. I feel that the key to this device is that it is very repeatable, within a small margin of error. I'm very happy with the results, and figure that I put much less time into making it than I would have spent trying to teach myself the muscle memory necessary to get proficient at sharpening by hand.)

- 10 replies

-

Times are difficult for all of us, so I have decided to extend the introductory sale pricing through the month of May on the Horse Creek Leather Works belt hole alignment/marking system. Regular price $74.95 – introductory price $59.95 including shipping to the lower 48. The system consists of 2 jigs that center and space your holes perfectly and quickly every time. The tip and buckle end jigs both have adjustable stops with the tip end marked at 6 ½”, 7”, 7 ½”, 8”, and 8 ½” from the center hole. The tip end has two versions, one with hole spacing at ¾” on center and 1” on center. Simply place over the belt and slide up to the belt end, close the sides against the belt, mark with the provided marking tool or your punch and you have perfectly spaced and centered holes. We call it the FTM-CTM (faster than measuring-cheaper than machine). You can order by credit card at https://hclw-belt-tool.square.site. They can also be customized at extra cost on a case by case basis. email: butch@horsecreekleatherworks.com phone 828 528 1831 Thank you

-

Hi, I recently bought a Barry King swivel knife and want to make sure that I keep the blade in the right condition. I'm new to the craft and I don't trust myself to manually hold a consistent angle on a stone. Previous posts I've seen recommend a Chuck Smith Big Red jig. Though, I'm having trouble finding a place selling these online. Does anyone know a good source for these? Or, is there an alternative jig that would work?

- 5 replies

-

- swivel knife

- barry king

-

(and 2 more)

Tagged with:

-

Hello everyone, I have been looking to find Chuck Smith's big red swivel knife sharpening jig and I can't find one for sale and it doesn't seem to be on his site anymore. Does anyone know if there is a place that sells one or has he discontinued making them. Thank you all. Andy

-

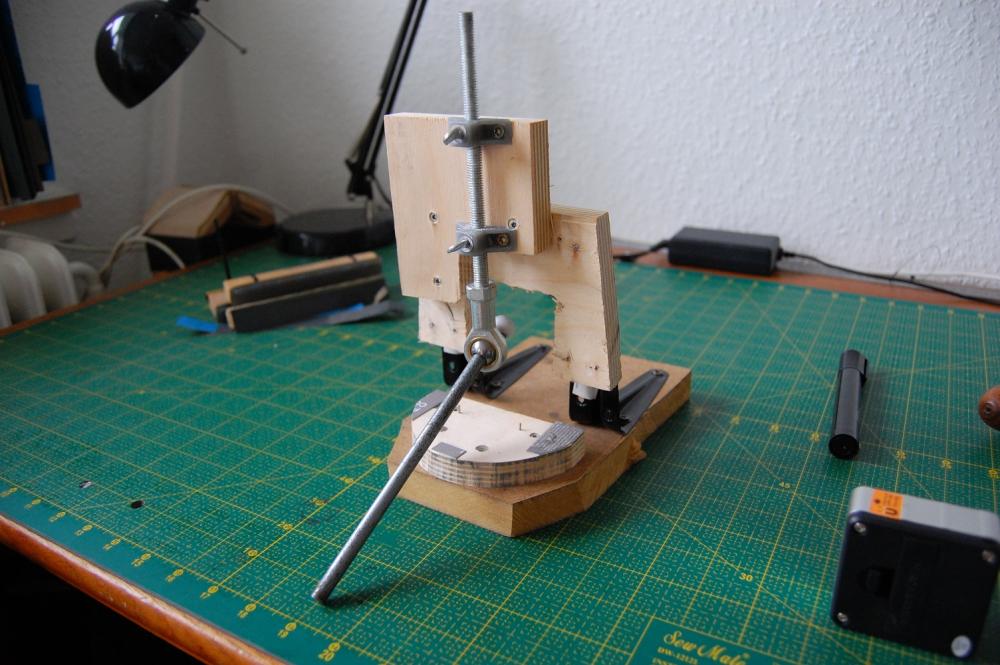

I have made a couple of sharpening jigs for round knifes before. This is version 3 and so far it works out great. It is not pretty as it was build with very limited tools. For a bit more information go here: http://andersenleather.blogspot.com/2016/08/round-knife-sharpening-jig-version-3.html

- 2 replies

-

- round knife

- sharpening jig

-

(and 2 more)

Tagged with:

-

Not quite leather but I'm pretty pleased with this creation from my new 3D printer. Created a Jig that allows me to lay this and lock it on the edge of a 1 1/2 inch belt. Although only 4 holes you can side it up and down the belt to get the 5-7 holes most people seem to prefer for belts. The end was rounded to allow to either cut or draw the guide lines for cutting the end of the belt. Jig is 5 mm thick and the two sides extend another 2 mm past to allow the belt to sit cleanly in the jig. Already thinking about how this could assist with stamping and spacing repeat patterns. Any other ideas where this would prove useful in leather work? Love to hear any thoughts.