Search the Community

Showing results for tags 'walking'.

-

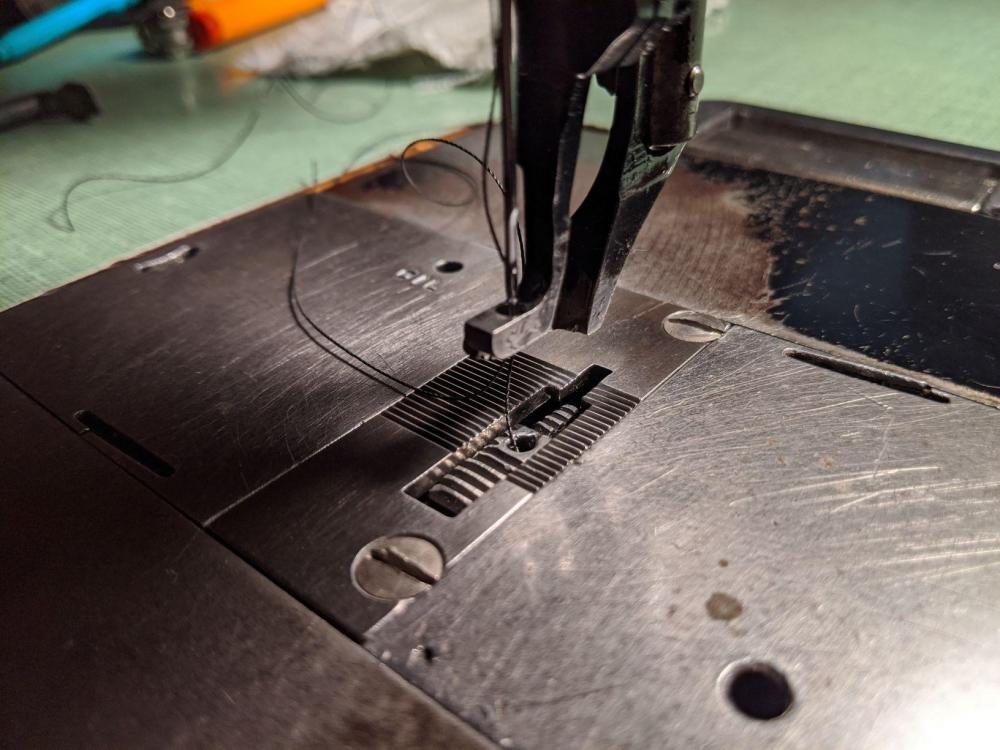

Hi All, I recently purchased a well used Singer 111W155 locally. Came with an old singer table, GE motor and Singer Clutch. I transplanted it into a more modern table. It was sewing fine but seemed to be skipping stitches. So i went shopping for new parts. So far i replaced the Timing belt (Was not broken but seemed about to), Hook (The basket was loose), New Tension Disk set, new bobbins, new needles. I cleaned it and lubricated it, Timed it and it is still skipping stitches. I tried everything... new needles, different thread different material and feed speed and still no luck. It seems to work fine for a while then every once in a while, it skips a stitch, sometimes 2 or 3 then goes back to normal. This can happen consistently on test pieces with about 3 inches of stitch so its pretty bad. The machine is quite worn and the feed dogs and throat plate seems worn also. The foot is a narrow foot set and also seems to be worn. I suspect what is happening is that the hook is able to get the loop most of the time but due to the slop in the foot or dogs or throat plate, the needle deflects and its just enough to miss that loop. I keep playing with the hook adjustment to get it close to the needle scarf and it seems every time i look at it, its in a different position (Either too far or touching the needle). I thought about the worst, too much wear in the needle bar bushings or even worst a bent needle bar but im really thinking it needs new feet, a new throat plate and feed dog. Before i drive myself crazy and spend more money on parts, can anyone think of what i missed? Thank you!!!! Andre

-

Okay I know you are all going to tell me this is a bad idea and that I should just buy a real leather sewing machine, but I don't have the money to make the investment yet, so I wanted to try this first. If I were to try sewing softer oil tanned leather with a normal sewing machine, what should I buy to make it work right? I hear that you can buy walking feet for normal sewing machines along with leather needles for them too. What do you guys think of that idea and what needle/ walking foot should I be looking at? Thank you for your advice! -Cole

-

Hello all! I'd like to introduce myself. I'm extremely new to leather work and vinyl work. I work with the USAF as an Avionics Technician on the B-1, F-16, B-2 and various other aircraft. I have a healthy background in electrical and computer engineering and maintenance. Currently I live in Japan, and I was lucky enough to come across a very rare care in the United States; an R32 gtr. So far, the car seems to be in good condition, even the interior is very nice for 25 year old car. It does have some cosmetic problems, and of course I want to do a custom interior retrim. I'm completely capable of trial and error, and taking my time with especially large projects such as an interior retrim. So I've been doing as much research as I can, and I decided to make an account here to get a first hand opinion from you guys. Currently, I've researched about the most prominent walking foot sewing machines, since I'll mostly be sewing vinyl. I've heard of the headaches that are solved by using a walking foot. I looked for pricing on the singer 111 series, and noticed that most of the pricing with motors and table almost always equal the price of a brand new Sailrite LS-1 basic. I've seen a few singer 95-15 around sewing leather, but how well does it honestly work with folded layers of vinyl and foam? I feel that it's a bit incredible that most of these older sewing machines, or general "used" new sewing machines are over 800 dollars. I feel that 600 USD for a brand new LS-1 is acceptable, but I was wondering what other machines I could use with heavy automotive / marine vinyl. Specifically, some allsport 4 way and some thick carpeting / foam padding. What other machines can you think of that don't break the bank? I'd say the main reason i'm looking for a ~600 maximum is because I would pay for someone to take the time and ship it to me (ie: paying extra for your efforts, plus the shipping cost). Of course, if push comes to shove, if anyone is in Florida, I can get one of my buddies to pick it up and ship it to me. What are y'alls opinion on my machine choices?

-

Hey guys, I've been reading up on the forums for a while now and finally joined to ask a few questions that I could not find the answers to. I am looking to build a medium to dark brown pleated tuck and roll leather motorcycle seat. (See examples attached) My questions pertain to the type and thickness of leather and the sewing machine needed to make this seat. I have been researching leather types and am a little overwhelmed with all of the options. I really like the inconsistency of brown oil tanned leather. I am not sure if this will be ideal for a motorcycle however. Will the oil rub off on my pants? Will it hold up under use? I looked at all the upholstery grade leather and it seems too shiny and consistent in texture and appearance. Should I use chrome tanned, oil tanned, aniline died, wax, urethane top coat? It seems to me like 3-4 oz will be the max thickness that I can use and still be able to pleat. Second subject is the type of machine. I understand that I will be needing a walking foot compound feed machine with #138? thread? Does this sound correct? I know that this is a very broad question that has many answers based on opinions, but where should I start in terms of manufacture and model for a machine that can accomplish the seats below? Thanks in advance for the help! Evan

- 16 replies

-

- motorcycle

- leather

-

(and 7 more)

Tagged with: