Search the Community

Showing results for tags 'walkingfoot'.

-

Hello all, So I bought this 300w last fall, and I have put many many hours into reading manuals, thinking and correcting all the adjustments the last owner messed up. I finally got it stitching within a month. I have two older mechanics who I’ve talked about the machine with, along with some Facebook users who agree that this machine is a hassle. I only have two questions left about this thing: 1. The walking foot. Even though I got the machine stitching, when I turn the hand wheel towards me and watch the feet move, it seems like the feed dog is moving backwards (up and towards me). Obviously I tried turning the hand wheel opposite of me, in which case the feed dog moved correctly, but then the vibrating (inner) presser foot is walking backwards. Is this normal for walking foot machines, or is the feed timing completely off? One thing that really makes me think it’s wrong is that when I lowered the feed dog height, the right looper began to hit a right side loop deflector screw (located on bottom of feed dog). There is a sheer mark on the screw where the looper obviously contacted the screw head repeatedly and drilled a path through the head (argh it was the last owner). The only reason the machine was working before I adjusted the feed dog height is because the previous owner maxed out the height of the feed dog so that the looper would make it past the screws without contact. Is my feed backwards? Feed dog too low? 2. The machine seems to be stuck on one of the longest stitch length settings. Despite following the manual, I cannot change the stitch length. The manual mentions adjustment between 4-12 SPI, but my machine is stuck at 6. What’s the problem? edit: Video of feed was taken while pressing lifter pedal to hold lifting presser foot out of the way IMG_9047.mov IMG_9049.mov

-

So hello everybody I am a total newbie to this whole entire forum I've been selling and been using this machine for about a year and a half now I got it from a friend of my mother's who has since passed but used to do car upholstery with it. So recently I just picked up some small jobs doing zipper repair on Bimini top covers and other small jobs mainly to do with canvas. Yesterday I went to go use my machine and when I went to go sew through the canvas to put the new zipper on the machine would so fine for a second and then break the needle,, as if it were hitting the plate and not in the center of the hole. I was trying to find a service manual for the 545 and the only thing I keep bumping into is the 1245 so my question here at this point is is that the same manual for the 545 that I have? P

- 8 replies

-

- breaking needles

- walkingfoot

-

(and 1 more)

Tagged with:

-

I have a protex ty3300 she is fabulous with layers but as soon as I go from stitching few layers down to maybe one, the foot gets stuck on the ‘ridge’ sometimes it had torn the leather also. It makes the stitches uneven and I have to try pull it out. how can I stop this from happening ?

-

I am new to working with leather. I have made many handbags but have only just started using leather and vinyl. I bought an industrial walking foot machine as I will be making a lot in the near future for a company. But I’m having issues with getting close to zipper teeth. I tried to take off a part of the foot but the machine didn’t like that!! Does anyone have any tips for me please? Need to get quite close.

-

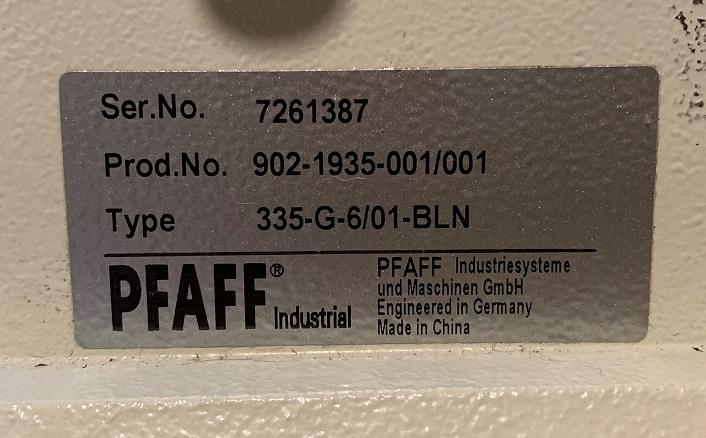

LIKE NEW PFAFF 335-G-6/01 BLN Cylinder bed Single-needle lockstitch machine with unison feed, large hook and alternative presser foot(walking foot)- I have three sewing machines and this one is getting used the least. Purchased a little over a year ago. One spool of thread has been ran through the machine. Makes a perfect stitch. Only reason I'm wanting to part ways with it is because I have a Pfaff 1245 flat bead that can do my lighter stuff and a larger cylinder arm for the heavy. This cylinder-bed sewing machine can be used for: Leather bags, purses, wallets, belts, straps, upholstery, chaps, etc.It is suitable for:working on tubular or pre-attached articles , standard sewing work on leatherware, bags and leathercraft articles , binding of shoes and leather warewith leather, imitation leather or textile tape , piping work on bags, suitcases and upholsteryALSO INCLUDED Complete Binding Attaching Parts For Pfaff 335Binding bracket complete with tape guide & screws / Needle Plate / Feeder / Set of Feet / 1" Raw Edge BinderTurn your cylinder bed machine into a binding machine cl 17/01 $1,900

-

Does anyone have any info on the Juki ls-341n I have found a ton of info on the non-n version. Like what size thread and max material, and if anyone can ballpark what they go for in used condition. Thanks for any help

- 3 replies

-

- walkingfoot

- 341n

-

(and 1 more)

Tagged with:

-

I have a walking foot machine - Techsew 2750 (similar to 2700, but with a bigger bobbin). Happy to have it. It's set up on with a table attachment to sew two flat pieces of 3-3.5oz together, 1/8" from the edge. Tension looks like its good - lock in the middle, machine running smoothly... except.. as it sews it veers the material, pushing it to the left (pushing the stitch line closer and closer to the edge). The only way I've been able to sew so far is to wrestle persuade the material to feed thru the machine at an opposing angle to somewhat try to correct it as it goes along. That doesn't work so well, and is leaving too much room for error on important pieces Upon a closer look, with and without the needle, the material is moving very slightly to the left, each time the feed dog and needle first come into contact with the material (center and walking foot still down (with walking foot about to lift if action continues). I've tried increasing presser foot pressure; all types of edge guide combinations, guiding by hand; no guide, no thread (with / without needle), and just running the machine at a slow speed to see how straight it sews on its own -- still shifts. I was originally using a center & left foot combo, but then switched to center & double foot to see if that would help with more surface area on the back of the feet touching the material. That didn't fix the problem either. The feed dog seems to be at a good height and has worked out well in keeping leather from getting pushed down, while not horribly marring the back as much as a sharp-toothed feed dog did (it's a smoother version, as the sharp toothed cuts up the leather). For a clean slate, I've set the machine back to the lighter presser foot pressure I have been using for a while now, and ready to keep trying to figure it out.. Since it's not a viable option for me to sew then cut material to size, what are some other things you all recommend I can try on the machine to correct the way the material is feeding thru? I've seen people just let their machine sew on it's own and it goes straight. That's ideal, but I'll even settle for a partial fix. Thank you in advance for the help! P.S. Techsew suggested increasing presser foot pressure so far, which I tried, but also looking forward to getting more feedback from this community as I continue to work with this out from all angles.

- 20 replies

-

- edgesewing

- materialfeed

-

(and 2 more)

Tagged with:

-

- 11 replies