All Activity

- Past hour

-

Thread Lubricating Cup for Singer 111w155 . What is it?

LMP replied to LMP's topic in Leather Sewing Machines

Thank you! That is very helpful. I do have some thread that is 100% cotton. Should I worry using it with this machine? Thanks again. Your response was very informative. Thank you. This is very informative. - Today

-

Thread Lubricating Cup for Singer 111w155 . What is it?

TomE replied to LMP's topic in Leather Sewing Machines

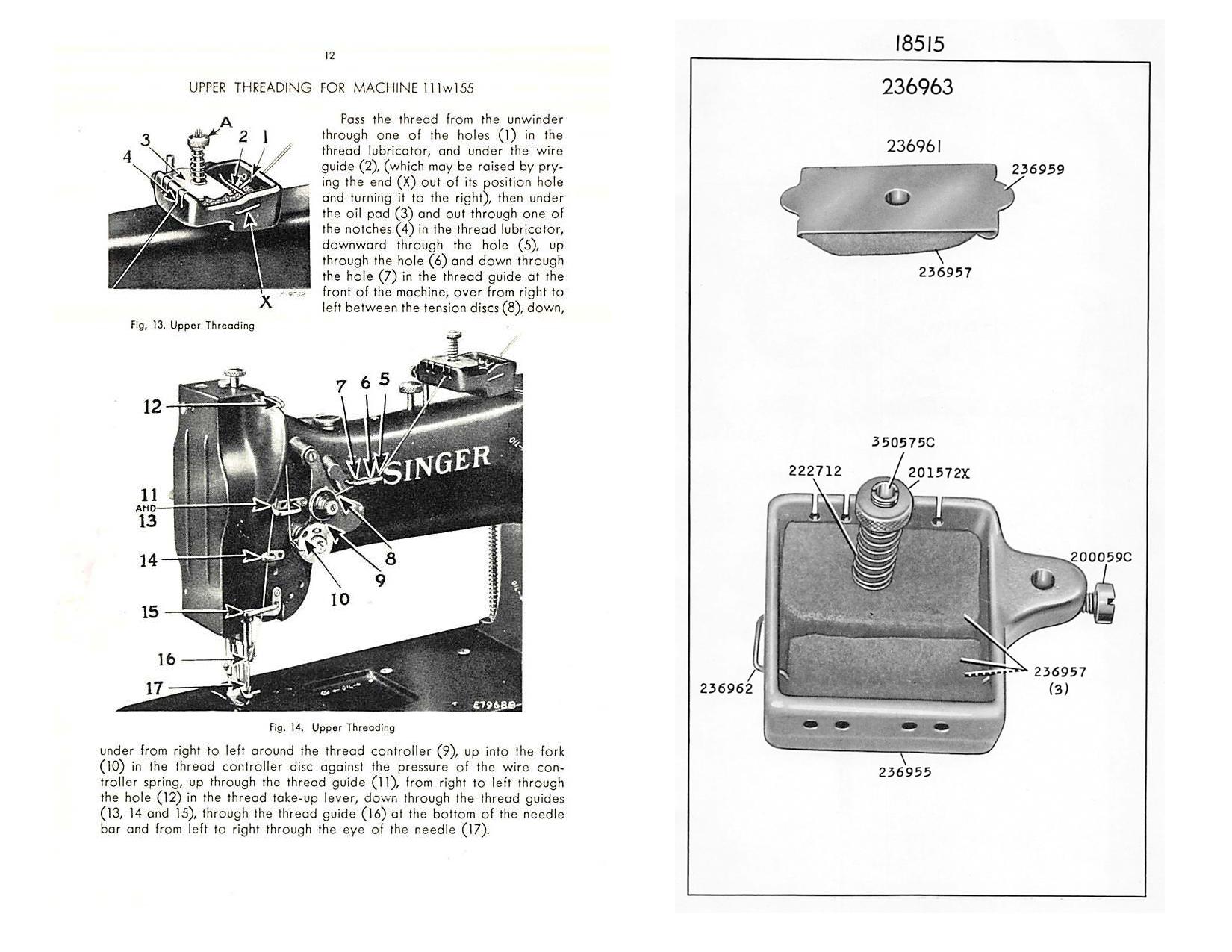

I've added a thread lube pot for sewing Biothane on my 441-type machine. The lubrication helps pull up the knots. Biothane is PVC coated nylon webbing that generates considerable friction on the needle. I don't use lube for sewing leather. Plastic add-on lube pots and thread lube are available from sewing supply stores. -

-

using glue with leather

stampingdelight replied to stampingdelight's topic in Leatherwork Conversation

@Hags what is the name of the 3m stuff or where does one find did try searching just came up empty -

using glue with leather

stampingdelight replied to stampingdelight's topic in Leatherwork Conversation

@fredk thanks will try that or at least get some to try, any place the best to buy -

Buffalo hide wallet Based on a Mascon leather design

stampingdelight replied to Second_Chance_Leather's topic in Show Off!!

looks good -

Thread Lubricating Cup for Singer 111w155 . What is it?

kgg replied to LMP's topic in Leather Sewing Machines

With today's modern bonded threads overheating of thread isn't as common a problem like it once was. Back in the 1940's the machine used cotton or nylon thread and it wasn't until the mid 1950's bonded polyester was used. Threads that were dry or fiberious or unbonded would overheat, then fray which lead to threads breaking under tension and speed particularly in a factory environment. The pad in the thread pot would lube the thread as it past under the oiled pad. The pad would provide just enough oil to reduce the friction as the thread made it's way to the eye of the needle from the spool of thread. That little bit of oil then reduced friction which reduced heat which reduced thread breaks then in turn gave consistent stitches, reduced down time and a better product. kgg -

Brian Caff joined the community

-

Buffalo hide wallet Based on a Mascon leather design

DieselTech replied to Second_Chance_Leather's topic in Show Off!!

Nice work. As fas as keeping your stitching irons straight. Just keep a keen eye on it. Check & double check before pounding it all the way thru. -

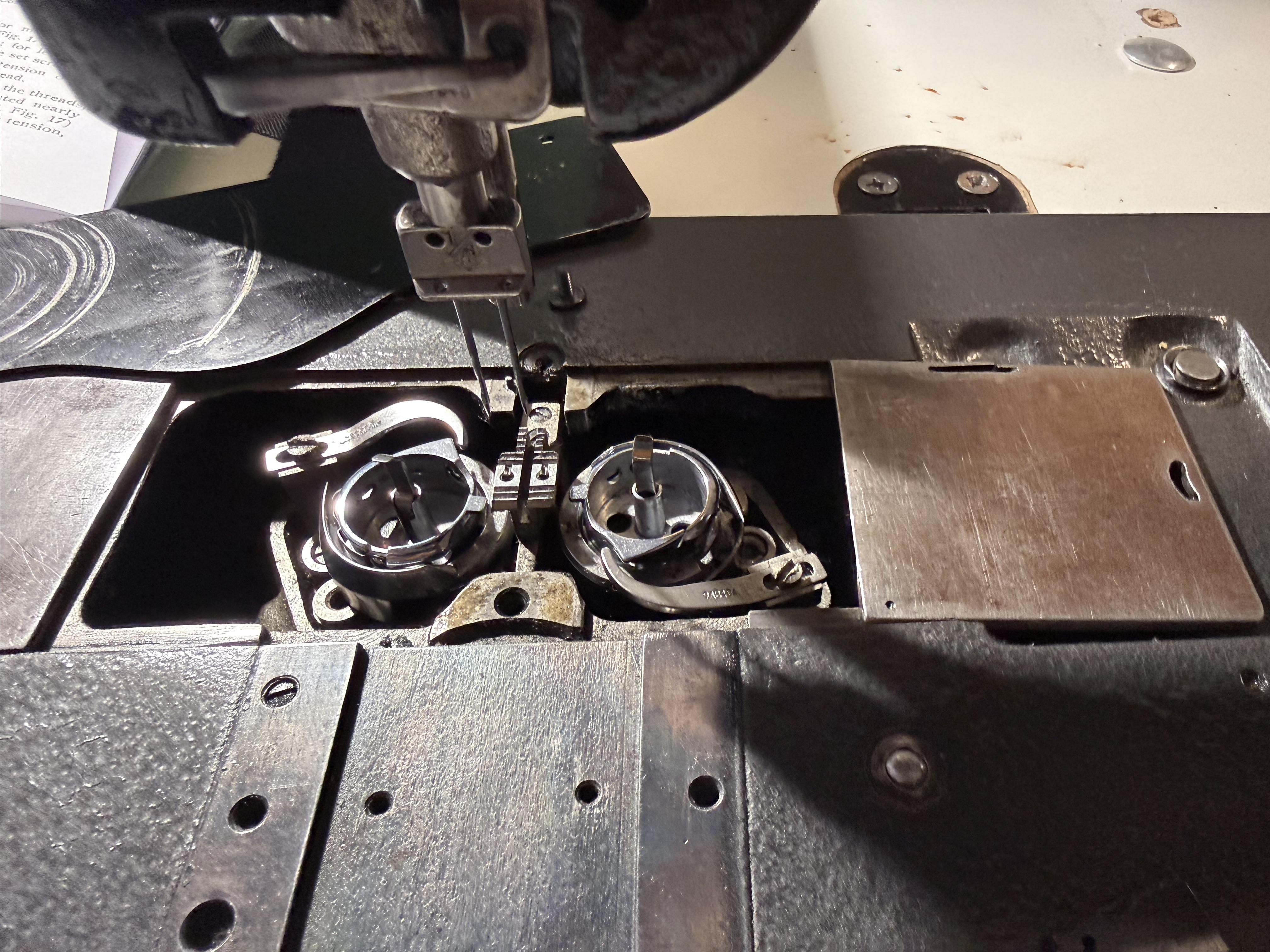

Hi all. I'm new to my Singer 111w155. In reading the manual which is for models 152-155, it describes normal threading for just models 152-154, and then there is a separate page showing the threading for the 155 model, which includes a thread lubricating cup that sits on top of the machine (see attachment). My machine doesn't have it, and from all my searches online, I don't see any other 155s that have it. Just curious, what is it, and does anyone know why the manual describe it as part of the 155 (not optional), yet all the 111w155s I see, don't have it either. Thanks!

-

Thanks for the info guys. I figured it was just a drip pan to keep the mess contained, that makes sense. As for the missing felt in the oil reservoir, I'm curious I guess. Still trying to figure out those stitch length markings. I can adjust the stitch to the length I want by watching the feed dogs for travel and then with a quick test on scrap piece, mostly just wondering what the numbers mean. @dikman yeah that clutch motor takes off if you're not careful!! It would be fine I was sewing awnings or something with long uninterrupted seams, line it up stand on the gas pedal!! Too hard for beginner to control for smaller stuff like I plan to be doing. And I've been driving cars, heavy trucks, motorcycles, tractors etc with clutches for most of my life.

-

Parts for Singer IIIw155 - which "List of Parts" to use???

LMP replied to LMP's topic in Leather Sewing Machines

ah, yes. 111. I meant to type that in my correction. Anyhow, thank you. -

A small ready-rivet would do. I use one on my little key-ring coin purses. They have a similar way of opening Loverly job. A late friend of mine would have liked these. She was a radio-ham and in noisy places we used to communicate with code in morse

-

New to the forum and wanted to introduce myself

fredk replied to Second_Chance_Leather's topic in Member Gallery

Brilliant!! -

yup, it works fine. I use d/s tape I got in a £shop, 3 rolls of 19mm x something for £2 edit; I forgot to say you can buy sheets of d/s tape. I keep and use sheets about 8 inches by 6 inches. They're very handy for sticking fabric lining on to leather

-

@Heafty turnip Welcome to the mad house errr, I mean the Forum

-

@Steve855 Welcome to the mad-house, err, I mean the Forum

-

PPS; @OGL By the way, Welcome to the mad house errr, the Forum

-

I’m new to this forum, have tanned a few hides and am just about to learn sewing. My dream is to build something out of leather from scratch. This includes harvesting the animal right through to sewing what ever I end up making. I thought joining up here could help me on my journey, well it has already! So far, I’ve chrome tanned at least a dozen wallabies, A Fallow deer and a feral cat. I have also experimented with alum tanning 2 cows. And these worked out ok. Just recently I have purchased a 2nd hand singer 132k6 which I have just rebuilt and have managed to get it to work. I have limited sewing experience but definitely have the passion and patience to figure it all out. Well that’s who I am and why I’m here! Thanks for having me.

-

The Cowboy labelled CB6900 is the down-under (Australian) version of the North America CB341 where both are clones of the Juki LS-341. Another option for those occasional needs would be a manual class 441 machine. There are three capable "one armed bandits", Tippmann Boss, Cowboy Outlaw and Weaver's Master Tool Cub. kgg

- Yesterday

-

@wizcrafts Thank you for the article! I would definitely be concerned about needle deflection and I don't think I'd be up for going through that adjustment process very frequently. I'm also not too keen on trying to source hard to find needles as well! I'm more convinced it's a case of two machines. Thinking about it more, I believe my best bet is to get a 1341 class machine now as I think it would fill a larger number of needs, while saving the super heavy stuff for an eventual 441 class machine. Side note, I'm assuming Toledo doesn't carry the 6900 as is not on their site. Maybe I'll call and see what Bob says. That's a good point. I've seen some other posters say they've done it with 207 in the top but not the bobbin but I think 138 is a safer bet.

-

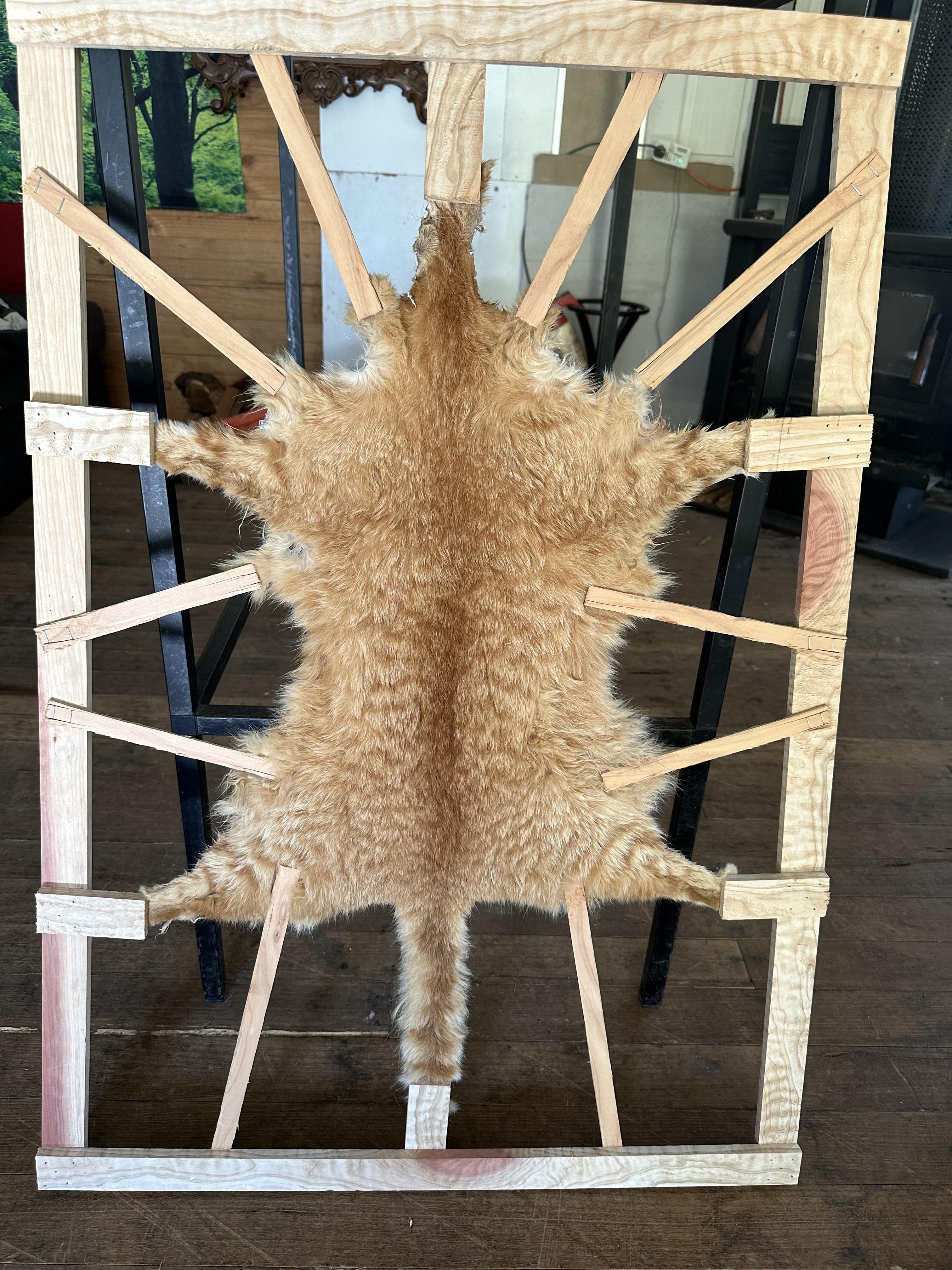

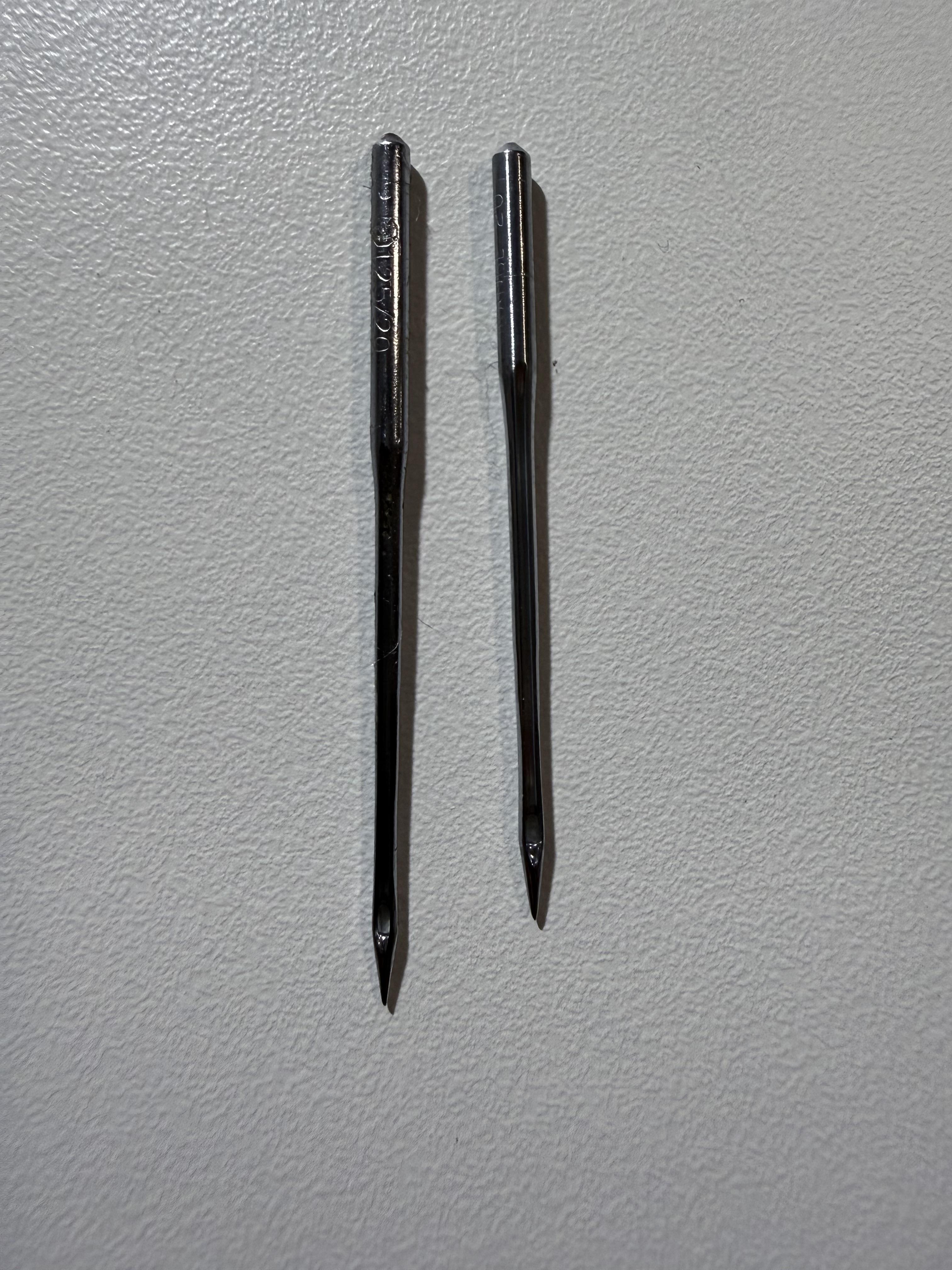

I need some helping locating information online on adjusting the hook timing on my double needle drop feed Singer 112w 115. I'm moving to a larger needle (20) and need to know how to adjust the timing for these types of machines. I have a needle bar that has no marks. The instructions for this machine says it can still be done even without marks on the needle bar, but also says I should set the stitch length to 8. I'm not sure when I change the stitch length if it actually changes. I bought this machine from a couple on Facebook marketplace that has an upholstery business, but I have not had much luck with consistent operation since I purchased it a few months ago. Everything from getting the right size table top from a swing machine supplier I would never use again to installing a simple knee lifter that turned out to be made horribly especially with this terribly made table top.

-

- singer 112w

- double needle

-

(and 1 more)

Tagged with:

-

Smttms8178 joined the community

-

Yes I did for the most part. I realized the knee lifter I bought wasn't made correctly. The 228365 wasn't moving up and down through the 228362 like in the diagram above. I got another one and immediately saw the difference. I'm still working on some fine tuning to get it to catch the knee lifter properly. The table top I bought has been giving me machine fitment issues from the start (don't ever buy a table top from Goldstar, tons of issues with it and shipping was horrible, I'm sticking with Prizzi going forward). I'm dealing with a timing issue now as I went to a bigger needle size and not finding much info on how to set timing on these machines. I'm about to post a thread for help on that now. Thanks for checking in.