-

Posts

7,804 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Wizcrafts

-

Absolutely love this Pearson #6

Wizcrafts replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

Pretty much all of the smart phones and all digital cameras allow you to adjust the size of the photos you are taking. Most will default to the maximum size, which is too large in bytes to upload to our server. To compensate, go to the camera app and find its settings icon (usually a cogged wheel, or a 3 lined hamburger icon). One of the settings may be labeled Resolution, or Image Size. Open that setting and select a smaller size from the list. I personally use the smallest available resolution for any photos meant for web page use, unless they are going to be expanded by clicking on them. Then I'll move up one size from the smallest. Basically, you only need 800 x 600 for web use. If details are important in an enlarged view, choose 1600 x 1200. Either of these resolutions will usually come in under our upload limit. per photo. The smaller the dimensions, the smaller the file size in bytes. If you have already taken photos that are too big to upload, there are computer programs (I use Paint Shop Pro), smart phone apps, and online services that can reduce image files, as well as improve or enhance their quality. The online services allow for larger uploads than most bulletin boards (BBS) and forums. Why are there limits on upload sizes? It is either a default setting that hasn't been changed, or a choice made by the website owner who pays for bandwidth and disk space used, or their hosting company who divvies out the available bandwidth and disk space among many customers on a shared server. Forums like ours are intensive on a server and its resources. It costs a lot of money to pay for the bandwidth and disk space consumed by our daily operations. -

Machine help- too much good info- please.

Wizcrafts replied to Brad2017's topic in Leather Sewing Machines

You're absolutely right about feet with teeth marking clear windshields. The Sailrite 111, Big and Tall, and Fabricator are compound feed machines taking standard walking feet. The Sailrite portables all have dual feed, with teeth on the feet. -

It depends on what sub-model it is (-103, -151, -153, 155, etc.), it's mechanical condition, condition of the table and type of motor. If everything works and there are no missing parts and the motor is either a servo or a slowed down clutch - and you can feather the clutch effectively - then $600 may be a reasonable price. The older generation of 111 machines didn't have a safety clutch that disables the drive to the shuttle in case you jam the thread. That came along with the 111w155 (I think). If the machine is missing parts, or needs replacements for worn out parts, and/or the motor needs replaced, $600 isn't such a good deal. It doesn't take long to rack up a hundred dollars for replacement parts on a 111 type machine. A new servo motor will cost about $130 to $160. If you need a bobbin winder it costs money. Ditto for a thread stand, flex lamp, knee lifter, etc, etc.

-

Machine help- too much good info- please.

Wizcrafts replied to Brad2017's topic in Leather Sewing Machines

The main difference I see between the walking foot machines meant for marine/upholstery vs. veg-tan leather is that the marine/upholstery machines tend to be dual feed with teeth on the feet, vs triple feed with smooth feet for leather. Dual feed means that the outside foot is driven in sync with the feed dog and helps to claw the material along as you sew. This is often a plus when one is sewing a long banner, sail, awning, tarp, Bimini or bench cover. These items are not made of leather and do not hold the tooth marks. Being slippery on top, the teeth help secure and move the vinyl / duck cloth along. The walking foot machines meant for leather sewing have compound, triple feed, where the inside foot and needle move in sync with the feed dog and the outer foot just moves up and down to hold the leather in place between stitch cycles. They work great on all types of leather and don't leave marks unless you install feet that have teeth on them (like zipper feet).. -

A lot of us, myself included, get our servo motors, v-belts and speed reducers from Toledo Industrial Sewing Machines. You would have to phone them to place an order. Others, especially members in Canada, get these items from Techsew, in Montreal. Folks on the West Coast probably get them from Leather Machine Company (Cobra). I prefer the Family Sew servos that have a simple pot or rotary switch to limit the top speed, rather than push buttons. The important thing to ask any seller is if the motor has a 50mm (2 inch) or smaller pulley. Most of these motors ship from China with a 3" or larger pulley meant to deliver high speed to garment machines that sew at 90 stitches per second. Leather sewing dictates a maximum sewing rate of about 10 to 15 stitches per second. That's where the 3:1 speed reducer comes into play. It not only makes the machine easier to control at slow speeds, but also magnifies the punching power at low speed, where servo motors typically fall off.

-

Not only does it not like #92 thread, but the shuttle driver position is set with a fixed pin through the shaft. The only way to get it to pass #92 thread without binding is to bend the driver outward. But, that changes the timing and creates a lot of slack between oscillation direction changes. Because the timing is fixed on the shaft, I cannot compensate for the changes made by bending the driver. It is best to come to grips with the limitations of your machines and live within them, rather than beating yourself up over things beyond your ability to change. In the end, I bought the 31-15 to sew garments, broad cloth and wallet interiors. I have 5 other industrial sewing machines that handle heavier or more complex work, all the way up to a CB4500.

-

I created a topic about the type of machine you need to sew leather, which is stickied at the entry page of the Leather Sewing Machines forum (this forum). It is many pages long and has questions and input from many other members. It will help you redefine your requirements for a proper machine that can handle what you intend to sew. In the scheme of things, $1500 is not a lot of money for a dedicated leather sewing machine that was built for the task and will last years, earning you mucho dinero along the way.

-

I think I paid $150 for mine and had to drive over an hour to pick it up. I didn't need it, but my Dad had one in his tailor shop for all of my life and half of his.

-

I will say that I like to use my 31-15 to sew thin wallet interiors together. I use #69 bonded nylon thread and a #18 leather point DBx257 needle. When it's time to sew the interior to the back I use my Singer walking foot machine, which is setup for #92 thread and has titanium needles. The hook and bobbin case has a lot to do with the maximum thickness of thread you can use in the 31-15. My machine is very old; from the 1920s. I can't coax it to pass #92 thread. Sometimes it has trouble holding the bobbin case in place and some won't stay in at all unless I bend the positioning tab in or out. Not the best engineering in my opinion --- but it's mine.

-

My 31-15 will not sew with any thread size over #69. It will not sew 1/4 inch of anything other than broad cloth.

-

I wouldn't want that cut off plate on a 441. If one needs a drop off behind the slot, the holster or stirrup plates are more effective.

-

My slotted plate is rectangular. It doesn't have a broken edge at all. When did you get these plates?

-

I have System 7x3 needles in sizes 19 through 22 for my CB4500.They are round point, but do a good job sewing chap leather and denim jeans. While I don't normally use my 441 machine for light sewing, there are times when I must use it with thin thread and small needles. All of the following struggles would be unnecessary if I had a medium duty cylinder arm machine, but hey... Assume that I am sewing a hemmed denim pants cuff around the outside, using Tex 80 Jeans thread (cotton covered with polyester). Before I alter the tensions I decide if I'm better off removing the feed dog and standard needle plate and replacing them with just the narrow slotted plate. The narrow slotted plate is less likely to allow soft material to be squished down into the slot than the feed dog with its bigger hole and huge rectangular throat plate. This requires removing the shuttle race cover and shuttle to get the feed dog unscrewed. If you do this, be careful to keep the screws and tiny compression springs from dropping out of the race cover. Carefully reinstall the shuttle and race cover, minus the feed dog. Whether I change the throat plate or not, the next step is to change to a #19 or #20 needle. These are System 7x3, round point. Next, I wind some of whatever thread I am going to use on top onto a bobbin. I probably won't fill the bobbin. I load the bobbin into the case and adjust the bobbin spring to get a small amount of pull resistance. It cannot be as tight as thick thread going into tough leather or the light material will be puckered. I thread the top with the lighter thread. I just cut the existing thread off a few inches from the guide over the spool stand, tie the ends together, raise the presser foot, then pull the thread all the way through to the guide above the needle. Since I can't usually tie a knot small enough to pass through the hole on the needle mounting bracket, I cut off the threads above the knot and feed the light thread through to the needle. Next, I back off the top tension and presser foot pressure spring adjusters. Denim and light leather don't need as much top tension or foot pressure. Set the stitch length for small stitches, like 8 to the inch. Sew a test stitch line into the cut off material to hide the knots. Ramp up the speed on the motor. Time is money. Sew around the cuff, starting at the inside seam, overlapping and backtacking over the starting stitches. I use the same steps to sew soft, thin leather (skirts, pants, caps). The conversion can take anywhere from 10 to 20 minutes, from start to sewing. It gets faster with experience. I refer to this process as dumbing down a 441 machine. I have used this technique with as small as #69 thread, but, #80 Jeans or #92 bonded is more reliable.

-

Cast Iron Again - Pearson & Bennion / BUSMC A1

Wizcrafts replied to Constabulary's topic in Leather Sewing Machines

Tell him that life will be easier for you and him if you get another sewing machine, preferably a cylinder arm walking foot machine. Sporrans and Kilts can be sewn on cylinder arm machines; I've done it. Then the only "ructions" will be the happy sound of machines and gears going tapokita tapokita. -

Female Hinges for a Singer 112w139 Sewing Machine

Wizcrafts replied to tmitch's topic in Leather Sewing Machines

Bob Kovar said he will search the old parts bins when he has time. Those are ancient! -

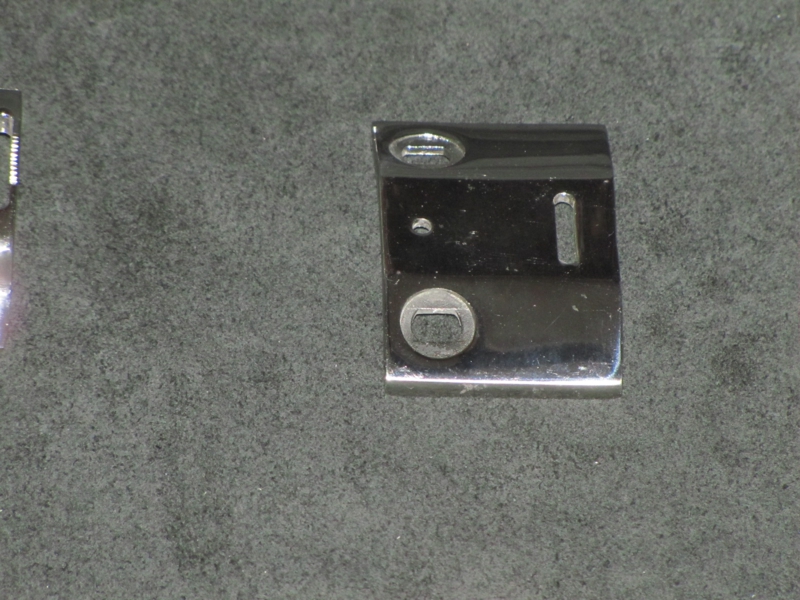

Female Hinges for a Singer 112w139 Sewing Machine

Wizcrafts replied to tmitch's topic in Leather Sewing Machines

Posting a photo of the pins on the machine and cut-outs in your table would help narrow down the exact part needed (there are several types). Once you know the style you need, contact an industrial sewing machine dealer to buy table mounts. They assemble and sell tables for their machines and have various machine mounts on hand. We have several industrial sewing machine dealers who advertise via ad banners on top of our pages, in addition to a few, like Gregg from Keystone Sewing, who assist members who have technical questions. -

Advice for the type of machine I should get

Wizcrafts replied to Melonie's topic in Leather Sewing Machines

If you only intend to sew about 10 ounces or so, a CB227R will do just fine. It is a medium duty cylinder arm machine in the same price range, but better with thin thread (up to #138). -

I completely forgot about round horsehide leather belting. I actually sell thinner (3/16") belts for home sewing machines. The 8mm belting (5/16") would be useful for bracelets. Holes can be punched into the cut ends and clasps installed. Anyway, I searched eBay and found a listing for 3/8" Oak leather belting. This belting is not totally round. It has a flatted portion on one side to facilitate punching holes for the steel clips that usually hole it together.

-

Hardwood; Here is a direct link to the rein rounder tool I told you about.

-

Sewing lightweight leather without a walking foot ?

Wizcrafts replied to littlewing6283's topic in Leather Sewing Machines

I think you have misunderstood my description of the roller equipped presser foot. It is NOT a wheel, nor does it require a single inline feeder. It looks like any other industrial sewing machine presser foot, but has several small rollers on the front and back. It is attached the same as a Teflon foot by unscrewing the existing foot and replacing it with the roller equipped foot. You will lose some of the available clearance under the foot, because this foot is deeper. Here is a link to an eBay listing for a high shank roller equipped foot. The photo should clear up any confusion. Titanium needles can be had in both round and leather points. You just have to find a dealer who sells leather points in the system and sizes you need. If you can't find leather points in titanium, just use plain steel leather point needles. As for the last question, if the machine is properly set up, the only thing you might need to dink with are the bobbin and top tensions to balance the knots. -

Use type 3L v-belts for industrial sewing machines and their pulleys. they are 3/8 inch or 10mm across the top. As already noted, these v-belts are sold by length in inches, not millimeters.

-

Sewing lightweight leather without a walking foot ?

Wizcrafts replied to littlewing6283's topic in Leather Sewing Machines

I would get a Teflon foot to reduce the drag leather has under a presser foot. But, make sure it never hits the feed dog directly or it will get scratched up. Also, there are roller equipped flat feet available with little rollers in the front and back. That foot isn't in danger of destruction from contacting the feed dog. To assist the actual feeding, there are three feed dog/throat plate combinations available for most common straight stitch machines based on Singer designs. Dress makers prefer the fine tooth feeder. Medium teeth are better for denim cloth and thin leather. Then there are large tooth feeders for moving heavy cloth and upholstery grade leather. I would have all three in my parts drawer. Finally, I recommend using titanium coated needles as they run cooler and don't tend to gum up if you use glue or basting tape to hold layers together. -

Exactly! I got the 15-91 before I got any industrial machines, for the second time around. I've had and sold off over fifteen industrial sewing machines, leaving me out of sewing at home from 2003 through 2010. During that time I was strictly doing computer troubleshooting and webmaster work (actually from 1997 through 2010). Any sewing I did was at M&M Leather. Now I have lots of big iron again.

-

I used to own a Singer 15-91 and can tell you what amount of leather it can and can't sew. Technically, anything that can go under the presser foot can be "sewn." But, in my experience, this machine is limited by two un-changeable items: 1: the semi-gutless motor; 2: the bottom feed only with fine teeth. I found that I was able to sew into about 6-7 ounces of bridle leather, with #69 bonded thread, using a #18 leather point needle. This required the foot pressure screw to be screwed quite far down. Sewing the same amount of veg-tan belting required a little more foot pressure. Moving up to an 8-19 ounce piece of the above leathers required the presser foot screw to be screwed all the way down. The drag on top fought against the feed dogs and shortened the stitch length. My attempts to sew 10-12 ounces of leather failed. The pressure spring couldn't hold the leather down and it skipped stitches and hardly moved along. I did try changing to a Teflon foot. This let the leather slide through with less drag. All it accomplished was the maintaining of the stitch length. I even bought a so-called walking foot attachment and installed it. This foot reduced the clearance under the feet and did very little to improve the feeding. The thicker or tougher the leather, the harder it was to penetrate and move it along. The motor would groan and eventually began smoking. I had to rebuild the motor to sell off the machine.