-

Posts

7,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Wizcrafts

-

M size pre-wound bobbins are sold in a wide range of colors and thread types for modern long arm quilting machines. But, I would still wind my own for bonded nylon thread in sizes 69, 92 and 138.

-

Pre-wounds will work fine as long as you can get the sizes and colors you need on the bottom. Otherwise, buy a dozen M bobbins and wind your own colors and sizes. The machine will handle thread sizes up to #138. The 280 types are dual feed machines, with teeth on the moving presser and feed dog and on the static (vertical motion only) inside foot. The needle is also static and moves up and down. This is okay for upholstery leather, cloth, webbing and Naugahyde, but not veg-tan or bridle leather.

-

Singer 29k171 "Another journey to the unknown"

Wizcrafts replied to jimi's topic in Leather Sewing Machines

No. The needle hole would be ~5mm too far to the left of the needle. -

Singer 29k171 "Another journey to the unknown"

Wizcrafts replied to jimi's topic in Leather Sewing Machines

Jimi; I finally remembered to measure the length of my gearboxes on my 29k71 and 29k172. The small bobbin k71 gearbox measures 190mm, while the 172 large bobbin model measures 200mm. The large gearbox is about 28mm wide at the widest part of the shuttle hole, while the k71 is just 25mm wide. I hope this helps. -

Double Needle Machine Uses (Singer 112G139 & 300W-1)

Wizcrafts replied to landrand's topic in Leather Sewing Machines

Post an ad for these machines in our Marketplace, under Sewing Equipment > Used. -

Consew 277RFS Compatibility/ Parts

Wizcrafts replied to WoodsideCo's topic in Leather Sewing Machines

Try Consew USA itself. Here is their Contact page. -

Singer 29k171 "Another journey to the unknown"

Wizcrafts replied to jimi's topic in Leather Sewing Machines

I got the missing Singer lock screw and installed it a long time ago. It is a thumb screw, similar to the ones used to screw on edge guides onto flat bed machines. -

Singer 29k171 "Another journey to the unknown"

Wizcrafts replied to jimi's topic in Leather Sewing Machines

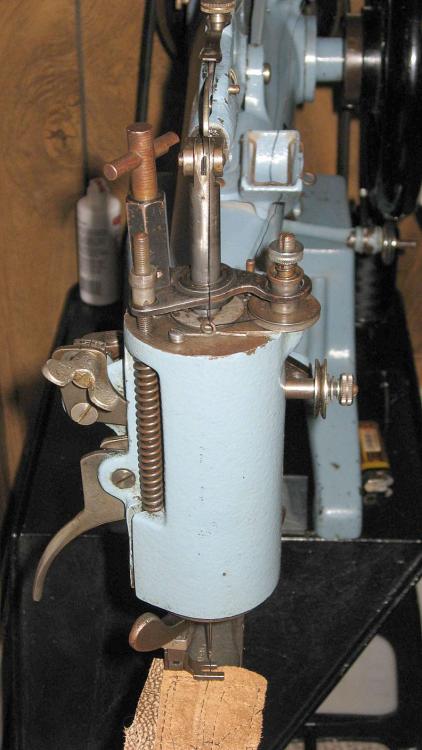

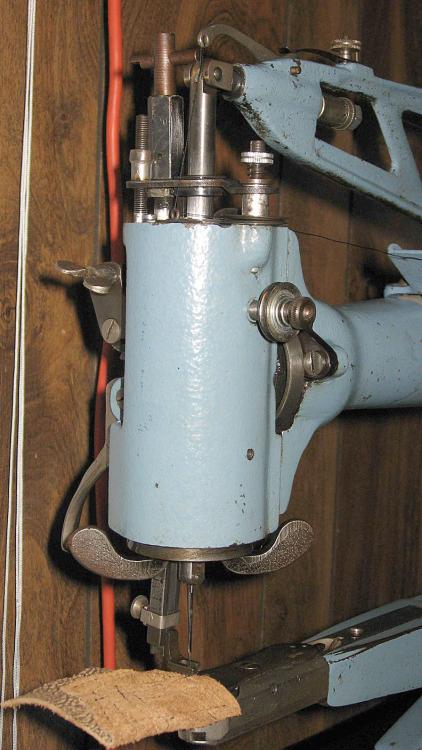

Jimi; I will try to remember to measure the length of the gearbox on my 29k172 when I go to work on Monday. Mine has a large bobbin. The T-bar on top is called a darning attachment because it causes the foot to stay up over the leather as you sew. The knuckle where the needle bar is mounted to the moving take-up barrel hits the T-bar if the arm is rotated so it faces the knuckle. This lets you move the work for whatever stitch length of pattern you want. I use it to criss-cross over torn seams on leather goods in for repairs. Sewing across to mend a tear in something is/was called "darning." In the old days, during the depression, Moms would darn holes in socks rather than buying new ones. The modern equivalent would be a wide zig-zag stitch. Note that my darning attachment has two positions. The half cut section just clears the leather, while the full bar lifts the foot all the way up. In fact, it releases the thread tension at the top of the stroke. So, I prefer the half lift position. Rotating it away from the mechanism restores normal operation. -

Singer 29k171 "Another journey to the unknown"

Wizcrafts replied to jimi's topic in Leather Sewing Machines

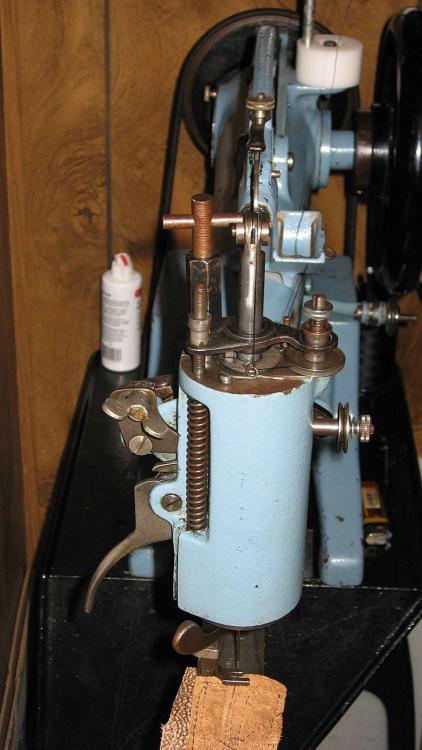

Here's my 29k172. It is the same as the 171, but with a long arm. Note that my machine has a darning attachment on top. -

I agree. However, this thread was not totally useless. It demonstrates the futility of trying to answer existential or theoretical questions about industrial sewing machines that are basically chunks of metal built for specific tasks. To make matters worse, the machines we use to sew leather are big, clunky beasts. Nothing beats hands on experience and actual use and experimentation. Seeing as how we have explored every nuance of the whys and wherefores of this strange topic, I am closing it. It was both frustrating and fun at times.

-

Correct Uwe. The 31-15 is just a bottom feeder. I have one in my leather shop in Burton, Mi. It is not able to use thread sizes over #69 though. I use it mostly with serger thread spools for tailoring and alteration jobs on light cloth. A 78-1 would be an interesting machine for a shop that does a wide variety of work, like we do at R&W.

-

This is unlikely due to the way the hook and shuttle is constructed. Also, the tension and take-up cranks may not be strong enough to pull up the knots of thick threads. Also, you will need to move up to a #24 or 25 needle to use thicker threads and this makes it harder to penetrate and then hold down the leather.

-

Any thread run through the 441 clones must have a left hand twist, or it will unravel or split. I have managed a short run of 5 cord Barbour's Irish Linen thread through my Cowboy CB4500, after running it through Puritan's Ceroxylon wax. This messed up the entire thread path, including the eye of the needle. I believe that is is best to limit the use of waxed thread to either hand stitching or a needle and awl machine, with a barbed needle.

- 4 replies

-

- cobra class 4

- cowboy 4500

-

(and 1 more)

Tagged with:

-

Very few machines can beat a Campbell Randall Lockstitch machine for top and bottom stitch appearance. The only other brands I know of that can match it are the Union Lockstitch (which I have owned), some Landis needle and awl harness stitchers and Tony Luberto's Classic (#9 clone)..

-

Despite your living in the UK, aside from shipping, motor voltage conversion and any import duty, is there a reason why you couldn't import a Cowboy CB4500 from the USA or Australia, from the authorized dealers/representatives? Your Pound is worth more than the USD. You might come out ahead of the game and get a properly inspected and setup machine that can sew out of the box (after assembling the stand, etc).

-

This topic is similar to Bill Clinton saying "that depends on what your definition of 'is' is!" To my understanding, the OP wanted to know how to know what he needs to know, in order to determine what sewing machine he should look for, in the event he has a project come up that requires a particular type of machine. This "is" my understanding of what his "is" is.

-

I bought such a presser foot set (left toe presser and slotted inside foot: for standard walking foot machines) from Steve Tayrien, owner of Leather Machine Company (an advertiser here). I keep the inside slotted alternating foot installed all the time, only changing the outer presser foot as needed for various jobs. I don't recall how much they cost as it was a couple of years ago.

-

pressor foot mods. Post any that you have done

Wizcrafts replied to Gregspitz's topic in Leather Sewing Machines

I use only Titanium System 135x16 needles on my Singer walking foot and 2 Singer patch machines. They penetrate Venture Tape without gumming up in the eye. Regular steel needles always gum up from Venture Tape. They are available in sizes 18 through 24. I use numbers 19 through 23 with the walking foot 139w109 and either 18 (#69 thread) or 19 (#92 thread) on the 29k patchers. -

180 kph = ~ 112 mph

-

I think t I think that the Dingo ate your baby!

-

Floyd; If you call Steve at Leather Machine Company, I suspect that he will send you a replacement bobbin tension spring. It's definitely worth a try.

-

I'm outta here

-

My 2 cents is as follows... If you are new to sewing leather/canvas/vinyl/webbing and are looking for an explanation about why one machine is better suited to sewing your projects than another, look at it from a strength point of view. If the projects can be sewn with fairly thin thread, like say bonded 69 (T70), which only requires a #18 (aka 110) needle, and the thickness will not exceed about 1/4 inch and is basically one level on top, and the work is not very tough to penetrate, almost any industrial sewing machine will do. It could have a flat foot, or a roller foot and be bottom feed only. As long as the material can be held down as you sew, there won't be skipped stitches and ratted thread. You don't start running into trouble until the material becomes very hard to feed, or penetrate, or has big differences in height from layers or seams, or exceeds the safe vertical working range of the needle and foot/feet. That is where an upholstery grade walking foot machine becomes a necessity. These machines typically are built with beefier take-up parts, larger shafts and better bearings. This allows the machine to penetrate dense materials without bending the steel parts. The tensions and foot pressure springs are also stronger than the ones used in garment quality machines. A benefit of using a walking foot machine is that it is usually designed to handle #138 thread and #23 needles. Most of them can sew between 5/16 and 3/8 inch of material, with a chosen few able to make it to 7/16". Walking foot machines also use longer needles than garment machines. As was already mentioned, flat work is best sewn on a flat bed machine that sits in a cutout in a table you can sit in front of. The standard table is 20" x 48". An average industrial sewing machine is about 19" long x 7" wide at the bed. There is usually about 6 or 7 inches on the right end, leaving you about 22" - 23" of flat table to the left of the needle. If there are any shapes below the top surface, or vertical curves, or if the object being sewn is cylindrical, a cylinder arm machine is a must have. Arm holes are best sewn on such a machine. Shaped cases or items with snaps, belt loops or clips, or any hardware on the bottom need some free space under the left edge to clear the throat plate and sew inline as desired. Cylinder arm machines can have any type of feed mechanism. But, if you are sewing leather or vinyl, which tend to be harder to feed than cloth, get a walking foot machine. For our purposes as leather workers, the walking foot machines we prefer are triple, or compound feed, with smooth, interchangeable presser feet. The dual (top and bottom) feed machines used by sail makers are not the right machines for leather sewing as they will mark the top and bottom with their aggressive teeth. IHTH

-

Is adler 67 GA 373 walking foot machine

Wizcrafts replied to Tote's topic in Leather Sewing Machines

I see that "Tote" has started another new topic about these same machines, so I am merging them together to avoid cross-posting answers. -

Is adler 67 GA 373 walking foot machine

Wizcrafts replied to Tote's topic in Leather Sewing Machines

The 67-373 is indeed a walking foot machine, with a flat bed. It may use a longer needle than your model 69: System 134-35, if it was setup that way. This machine will handle #138 thread, top and bottom. However, it has a standard size bobbin. Here is a video I found of someone test sewing an Adler 67...