lazyd

Members-

Posts

105 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by lazyd

-

I have a flip phone. I use a camera with a card...??? (I'm old)

-

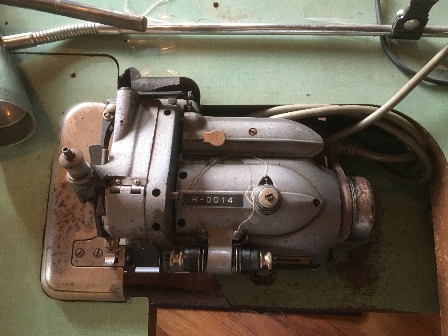

I bought this Singer Class 7-5 machine a few years back thinking I would put a motor on it and use it. Bought an Adler K205-374 and lost interest...It is missing the pressor foot lift lever. Looks like the previous owner had a lift system that pulled from overhead or something...??? I threaded it and turned it over by hand. It picks up the bobbin thread and sews 2 thickness' of 7-8 oz latigo. I would like to get $200 for it as is with table. Or trade for some thing I can use in my shop. Lets Talk. I'm in SD. Thanks I cannot figure out how to resize a picture. Mine are too big I guess... Maybe some one can walk me through that...???

-

Your original anvil is crimped in. Your machinist should be able to make you one that will screw in to the New anvil. I was just getting by with what I had laying around the shop. And I have a lot of STUFF laying around my shop.

-

Sorry it took me so long to get these pictures on here. Hope they are clear enough so you can see. I forgot to mention that to help hold the u shaped piece below the groove, I ground a 5/16" nut thin enough to fit inside it and screwed it in. The threaded block is a part I got from Weaver I'm guessing about 3-4 years ago. Seems they don't carry them any more...???

-

I have changed over several of the old Rex riveters to the Weaver splash anvil. Weaver use to sell 2 types of splash anvil. One had the threaded top and the other had a grooved top like yours. They also sold a piece that took the place of your U shaped part. It was a solid steel part with a threaded hole to screw the splash anvil in. It worked good. Earlier this Winter I was rebuilding a Rex for a friend and I asked them at Weaver about this part. The person I talked had never heard of such a part... I miss Vernon. What I finally did is carefully put a small screwdriver in the slot of the old U shaped part and opened it up so it would come off the old anvil. Then on the new anvil, right below the threads, there is kind of a groove there I was able to squeeze the U shaped part in there with a pliers. It seems to work. I also noticed the machine work on the splash anvils I got were not real consistent. Some split the rivets better than others. Maybe later I can post some pictures of the parts I am talking about. Good Luck------Bill

-

Hey Mike, how are you. How's the Landis #1 working out for you? The snow is leaving a little each day. Our creek is up but not too crazy yet. Tomorrow it is supposed to get pretty warm. We'll see what happens then.

-

Finished this harness today for my team. Did something for myself once. Worked on it off and on all Winter. Not a fancy one just one to use. Thought I would post a picture.

-

Yes, They look like my old one. I will personal message you Thank You!

-

I am looking for a good Stitch groover. The set screw in the end of my old one finally stripped out after 20 years use. I ordered a new one from Weaver and was I ever disappointed. The blade seems to big and clunky and I can't seem to get it sharp. Anyone have a suggestion or one for sale ?? Thanks

-

What type/size/thickness leather are you looking for? I can pack a lot of scraps in a post office flat rate box. I have big boxes full I would love to sell!

-

I put JB weld in it yesterday. Sewed with it today. Stitches lay a lot smoother. Not as smooth as the Landis #3 I used to have ... Thought I was updating Ha!

-

I saw the feed dog in the catalog. But I like to do things on the cheap! Thanks

-

Thanks Glenn, I can't believe I missed that. It is in their supply catalog. Weaver is my main supplier. I bought this machine used and have a little to learn about it yet. I had some JB Weld in that groove for a while but it fell out. I'll try again. Thanks

-

I am not sure if there is a smooth feed dog available. I was hoping someone on this forum would tell me...??? I think I have the tension right... I cut a sample piece in half and the threads are crossed over about exactly in the middle. I was hoping someone would tell me what that groove in the feed dog is for... I'm building a harness and the backside of the breeching, next to the horse, has the thread sitting on top of that bead caused by the groove in the feed dog. I AM going to tighten the bottom tension a little and see if that helps. Thanks

-

I have a question about my Adler K205-374. Can someone tell me why there is a groove in the bottom feed dog ahead and behind the needle? It leaves the bottom thread sticking up above the surface of the leather. I think it should be at least level or pulled into the leather a bit...??? Is there anyway to remedy that? Thanks

-

Mike, My SIL found these two numbers, says that is all she could find...??? Not sure if they are serial #'s.

-

Here is the extra I have. It has "Character". Make me an offer or trade me something I can use and pay the shipping from 57028. It sets #9 copper rivets but is stamped with a 4 on the side ...???

-

I have one I would sell or trade. It is mushroomed on the end where someone used a steel hammer, but will work fine. Sets #9 rivets. Make me an offer.

-

Where would we look for the serial number ?

-

Hey, Thanks for all of the info and the video ! That really helps. Maybe we should reconsider...??? But, we are limited for room and we don't have any manual on it to even show us how to thread it...

-

We are in Eastern SD. About 40 miles North of Sioux Falls if that helps.

-

My Sister-in Law bought this machine thinking it was something else. Can anyone on this site use this machine ? It seems complete and turns free. We never used it. It has been in dry storage for several years. Asking $175 Thanks

-

Thanks again Guys for all the Good information. It really helps. Keep it coming !-------Bill

-

Thanks for your input on that machine. It's nice to know it would possibly be reliable. Maybe we should have a little wider zig-zag for what we will be doing...??? Anyone else have an opinion ? ----------Bill