-

Posts

147 -

Joined

-

Last visited

About Chef niloc

- Birthday 08/21/1974

Profile Information

-

Gender

Male

-

Location

Ny

LW Info

-

Leatherwork Specialty

Knife sheaths

-

Interested in learning about

All

Recent Profile Visitors

7,959 profile views

Chef niloc's Achievements

Member (2/4)

-

Honest answer just because I don’t have one. Paul makes great knives and I’ll definitely get him to make me one. Sharpening, maintenance dropping not a big issue. 2x72 leather belt on the grinder loaded with fine diamond compound usually does the trick.

-

anyone know a maker using MagnaCut steel to make blades (swivel, and or round knives ) before I start making special requests (light nudge to Paul)

-

Old round punches - yard sale finds - need some TLC

Chef niloc replied to Sprocket's topic in Sharpen it!

Another way if you don’t have the power tools is the “mousepad sandpaper sharpening technique” there’s tons of articles on it if you Google it but basically it’s just what it sounds like.Aautomotive wet/ dry sandpaper ( 500, 800, 1000 grit is what I use) on top of a somewhat forgiving service. Rubber cutting mat or a newspaper/ magazine I’ve heard works. I find it best to spray It was glass cleaner ( the aerosol one) as opposed to just water.. -

I know I’ve seen them before usually made out of metal or some type of plastic I think? Can’t seem to find any now. I’m wanting some basic floral Oak-leaf, Sheridan style ones primarily for belts to help me get started (I’m brand new to scrolling/ and a novice swivel Knife user. Hope to get to them Sheridan show this upcoming year, but anyway, Anyone know of quality ones without having to have them custom-made?

-

anyone have any tricks that keeps the glue fresh and from thickening in between projects? I’ve tried taping around where the brush meets the opening and the solvent fumes seem to eat through every adhesive. I’ve tried.. I can’t find the metal can that the whole pot fits in and plastic ones disintegrate. I don’t really feel like dumping it out into its original metal container in between projects. Any advice??

-

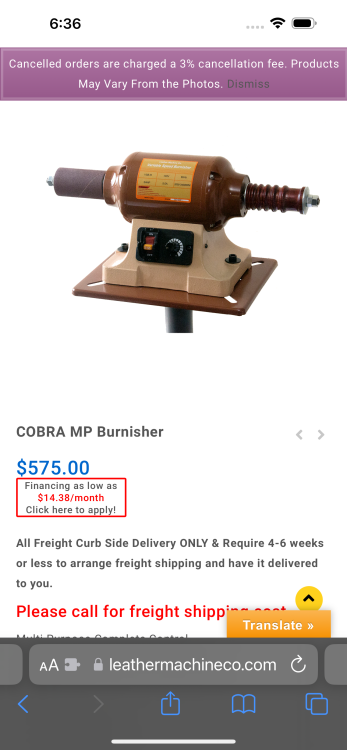

Thanks Tom didn’t think about the variable speed aspect as I currently is a drill press which has variable speed the extra buffer I have laying around doesn’t. By the time you buy the attachments looks the the cobra is running about $300 or so more to have a dedicated machine certainly works considering

-

Hii i want to make a bench burnisher like the cobra MP one out of a bench buffer. I found a sight ( thanks to a search here) that has the grooved wooden attachment, but does anyone know what the correct attachment ( and possibly where to get ) to fit the sanding drums to the other side? Looks like one would need a rubber drum or contact wheel of some sorts with a half-inch arbor hole? But I could be completely wrong

-

I know this is a pretty old thread, but since there still doesn’t seem to be a lot of information out there on the subject, I thought I’d add something I’ve come across over the years. The machine. The OP is talking about uses “pressure” and “friction” to do its job. What do those two things (pressure & friction) produce? You guessed it heat! The glass hand slickers posted above work 1000x better if working on a hard flat very warm surface. I put a granite stone. (like what you use the stamp on) in the bottom of a gas oven that’s off ( so just the pilot flame) , electric oven lowest setting would probably work. The thick stone holds the heat for a good amount of time. I’m sure there are lots of ways to achieve this though. Very Important part regarding heat. To hot you will kill/ destroy the leather. I like to call it uncomfortably warm to the touch. In other words, I can place my hand flat on it and leave it there without burning myself, but it’s not exactly comfortable. hopefully that helps someone someday.

-

Could be wrong but I think you may be talking about old japanning? A form of baked enamel made from asphaltum that’s there’s no “true” historically accurate product on the market to use . There are old recipes to make it but I found the old recipes are toxic and difficult to make and work with and more trouble than it’s worth. Dupli-Color DE 1635 is a cheap automotive spray paint that 100% looks exactly the same. It’s very durable not as durable as the real stuff, but tough. You can bake it on to increase durability but not necessary. as for rust old paint removal look up “electrolysis rust removal” i’ve done countless antique tools with this method, and it not only removes the rust if I understand it correctly, it reverses it and turning it into black oxide, so your not eating away the old metal and it gives things a wonderful dark” old look” with pretty much no elbow grease

-

The two posts above have very valid points in regards to steel hardness, one that I touched on but probably didn’t take the average users or knife makers into consideration. I use a leather belt loaded with diamond compound to maintain my edge and find that I only need to actually sharpen the knife once a year ( this is under moderate use), to sharpen These days I am using a belt grinder That makes quick work of it, but I did and still I do Use the mouse pad method I described above when I don’t feel like breaking out the heavy machinery lol. On reflection I’d Have to agree with The two above members That a “softer steel” is easier and probably more practical. And as for the Rc Suggestion I posted, I was wrong chuck is right I should have double checked my “facts” before posting. Looking back at old correspondence the round knives I’ve had made are 58Rc not 68, And some other knives as high as 62. So it appears I was off by 10 which is actually a huge mistake. Again my apologies. as for the grind (convex) suggestion I made ill still stand behind that. It being a “axe” grind as chuck called it is absolutely true. That’s why the edge holds up the longest as it has “more meat” behind it. This grind is possibly why I don’t encounter any chipping problems?? As for it creating more drag this is also probably true in comparison to a flat grind. However I don’t “ slice” leather, Especially when using a round knife. My cutting technique may not be correct?? But I almost always use a “push cut” and sometimes maybe a little bit of a rocking motion at the end. The convex edge I find pushes the leather apart as I cut thus making it easier. Again just what I’ve found to be the case with the knives I’ve had made for me. what diamanté’s says about chef knives is probably a discussion best suited for a different forum as it’s a topic I’ve found myself in the center of many times and is a whole topic onto its own. But I will say as a professional Chef ( leatherwork is just a side thing) a hard steel is one I prefer and has definitely become more part of the norm over the past 10-15 years or so with many chefs. FDICK ( a very old school “ German kitchen knife company) started making “butchers steel “ especially designed for this reason,, it’s called there “ Dickoron“ line Absolutely gorgeous and works fantastic IMO. However I’m in the a Minority in that I also prefer a convex grind or at the lest a convex edge on kitchen knives. this is something I have tested and done extensive reports, articles, presentations on, but again it’s off subject here. as for the hardening of Thinner steel I am not a knife maker or blade Smith But I have had some amazingly thin and extremely durable knives made for me by the makers Bill Burke, Michael Rader, and Murray Carter. again off topic I just though I’d mention them though Incase some were looking for some posable research references, or excellent custom knife makers

-

Gorgeous work man! Love the way you Did the Transition From the horn to bolster to blade, very “ Organic“ beautiful flow to it. the file work is A nice touch (And came out great), not something you see much these days, and your right it definitely makes it look like you know what you’re doing .

-

I see this is a somewhat old post but just in case your still looking and or if someone finds this thread in a search looking for similar information: I’ve had a lot of custom knives made from many different makers over the years, it’s kind of “my thing lol’. Hers what I would do: ‘tell him you want a convex grind right to the edge, that’s the most important part. Convex edge will cut better and more importantly hold up longer. A bit more tricky to sharpen yourself but easy to maintain on a leather strop and to resharpen just serch “mouse pad knife sharpening” Which is basically using as you guessed it a mouse pad and wet dry sandpaper, I’d recommend this way of sharpening a round knife to anyone and everyone, there may even be a post or two on this sight about it, dont remember ? Tell him to make it as thin as possible, trust me it won’t be able to make it “ too thin“, most (all in my experience) knife makers tend go to thick, telling them to go as thin as they can has given me the best results over the years. 5 1/4 to 6” tip to tip is kind of a big knife IMO but if you have one that size and like it then great, I personally prefer mine about 4-4.5”; again just my preference. 2nd best bit of advice (next to the convex grind) is give the maker a knife that you like, you can talk with him about any changes to that design you may want but at lest he has something to work off of. At the very least some pictures (make sure they are to scale in size) I don’t want to discourage you (or anyone reading this ) but I thought I’d mention that in my experiences a maker who has never made (or even used) a leather round knife has very little luck making a good one there 1st time out. The good/great ones I’ve had made were from makers who already had experience with them, and most were master Blade smiths with years and years of experience under there belts. They are kind of tricky to grind as they are different from most other types of knives a maker would be use to making. best of luck oh you/ he didn’t mention what type of steel (or I missed that) 52100 is without a doubt the best steel for the job. It is carbon so it could rust and the tannins in the leather will make maintaining the edge (leather strop) more frequently necessary, but 52100 is the best cutter, go about 68-72 Rc. If a stainless steel blade is a must, and or a blade that won’t require as much maintenance I’d go with AEB-L it’s the steel used to make razor blades, very very close to 52100 in cutting performance, may even be a better choice if you’re doing a lot of cutting at one time/ production work.

-

Someone please tell me whats the name of this ??

Chef niloc replied to wang369's topic in Leather Tools

Absolutely fantastic, very nice looking. $200 is a good price. You remember the website? I’d like one of those