jlsleatherworks

Members-

Posts

25 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jlsleatherworks

-

What needles and where do I find them?

jlsleatherworks replied to jlsleatherworks's topic in Leather Sewing Machines

Makes perfect sense, thanks again! -

What needles and where do I find them?

jlsleatherworks replied to jlsleatherworks's topic in Leather Sewing Machines

Thanks for the guidance! Know that I know what I need getting it should be easy enough. Just my curiosity getting to me but could you explain what the size numbers mean? Are they actual dimensions of the needle or do they represent something else? -

I have an Adler 104-2 and need some needles for several years I have been using needles that came with the machine and they are now past the point of use. The needles I have are marked Schmet 160. I'm not sure what needles I need or where to find them. I am using 277 thread. Any help would be appreciated! Thanks!!

-

Leather Darts Case

jlsleatherworks replied to Marten's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Cool I really like the brindle effect on the dye, mind sharing how you did that? -

I'll mostly be doing knife sheaths and holsters maybe an occasional closure on a bible cover/pad folio or the like usually one layer of 9-10 oz or doubled 4-5 oz. The stuff that Tandy sells appears to have a 5/16" post I'm measuring 2 layers of 4/5 oz at a hair over 3/16".

-

I have never used snaps but have a couple projects that need them. My question is about the post length, should it be equal to the thickness of the leather? I don't want to order the wrong size...

-

I like it! My brother collects axes and hatchets and I've been thinking of making a similar one for him yours is inspiring!

-

Couple Of Knife Holsters

jlsleatherworks replied to jlsleatherworks's topic in Gun Holsters, Rifle Slings and Knife Sheathes

The quilted pattern is one of my favorites I think it is a classy look and it's so easy and fast to do. Sometimes I wonder if I use it too much... -

Couple Of Knife Holsters

jlsleatherworks replied to jlsleatherworks's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks for the kind words guys! I consider myself a hobbyist but these little knife holders seem to be quite popular and are beginning to make my hobby a self sustaining operation. -

First Pair Of Work Boots

jlsleatherworks replied to Tim Schroeder's topic in Shoes, Boots, Sandals and Moccassins

The boots look great, but I can't get past your workbench! That thing rocks! Now I have something to aspire to... -

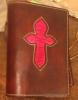

Bible cover I just finished, going to be a v-day gift for the wife. Hot pink ostrich leg inlay, 4.5/5 oz HO fiebing's pro oil light brown. The dye came out pretty splotchy but overall I'm pretty happy with it, I hope she will be too!

-

First, thanks for the compliments. The stitch line is one of the glaring mistakes for me this is the first time I have successfully* completed this pattern the last attempt I had the stitch line too far in and try as I might couldn't get the gun in the holster so this time I moved it out and screwed up the angle in the process. The bottom is actually open its just too long, next time I'll shorten the pattern just a bit.

-

After a few dozen chew toys and a few for personal use I have finally constructed something I don't mind showing others. It's not perfect and a long ways from where I want to be but I finally feel like I'm making forward progress in this craft. Please give your opinions so that I can learn from this one to make the next one even better. Thanks!

-

The machine is a juki lg 158 long arm walking foot it is brand new never even been threaded but it's about 4 years old. It retails new for about 9200-9600 I'd take 6000 Obo and delivery could be arranged locally for free, further for a small fee. It has a nice table and just needs a home where it will be put to use.

- 3 replies

-

- sewing machine

- juki

-

(and 1 more)

Tagged with:

-

Hi all, I have a brand new (about 5 yrs old but never been used) Juki sewing machine, it isnt really a leather machine though it might be usable for that purpose. We bought it a few years ago with the intention of using it to sew industrial quilted tarps that we were involved with at the time and that never panned out so it has been sitting in storage for about 5 years now and its time to find it a new home. I know this forum is geared towards leather only but thought that someone on here with experience in industrial sewing machines might be able to provide me some direction in trying to get this thing a new home. Thanks! Justin

- 3 replies

-

- sewing machine

- juki

-

(and 1 more)

Tagged with:

-

Those of you that vacuum mold holsters, what do you use to do so? I have one of those "as seen on TV" vacuum sealer for the kitchen and have been thinking of trying it on holsters but Im not sure if it produces a powerful enough vacuum to actually mold a holster. Any thoughts?

-

The tension wheel I'm assuming is the black disk on the left hand side of the machine? The thread is also a mystery to me I haven't looked on the bottom of the spool to see if its marked. I don't think i need any parts right now as everything seems to be in its place, but should I need them, where can I find parts? Thanks!

-

It is a big industrial type walking foot machine mounted in a table with a motor mounted underneath. Here is a picture I found online, it is not exactly the same but very similar, I will get some pictures of mine when I get home in a day or two ( i work out of town).

-

My wife found an old Adler sewing machine for sale and bought it for me, it appears to be in excellent shape (old but well cared for) problem is I know nothing about it! The fellow she bought it from has since moved and I have not been able to contact him, so I'm pretty much on my own with it. Through the research I have done I believe it may be a 124? series machine. However, I really dont know that for sure. Luckily it was threaded and had a full bobbin in it so I was able to figure out the basics and get to sewing with it. It makes a decent stitch but I think the thread tension may be off because sometimes it doesnt pull the lock back up into the hole and the bobbin thread breaks occasionally. Does anyone know a good online resource for these machines where maybe I could find a users manual or something of the like? Any help would be greatly appreciated!

-

Tooling Won't Stay

jlsleatherworks replied to jlsleatherworks's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I think my problem is that I have my leather overly wet, I have been soaking it for 15-20 mins, after browsing this forum i have realized that is WAY too long. I am not doing super complex design just a basketweave but I think I'll try one with no design and concentrate more on the fitting/boning. Thanks for all the tips and pointers!! -

I am new to all this and have been trying to teach myself to make holsters, I have made a couple so far that I have been overall pretty happy with. I have stamped a basketweave design in them that looks really nice. The problem I'm having is that when I wet-form it the leather swells and the pattern becomes very light. Maybe I should not try to stamp peices that I plan on wet forming?