-

Posts

1,442 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by mlapaglia

-

Call Tippman and talk to one of their techs. They are great with phone service and till take all the time needed to get you going.

-

Make sure you cycle the handle completely. Pull it all the way down and push it all the way up. Short strokes can cause skipped stitches and other problems.

-

How Do I Get My Holster To 125 Deg To Harden It

mlapaglia replied to mlapaglia's topic in How Do I Do That?

You just need to get the temp of the leather up to 120-130F for 5-10 minutes. This sets the collagen in the leather to hold the shape. You do not have to completely dry it in the box. I take mine out after it gets to temp and place it in front of a fan so the rest of the moisture is blown away and not reabsorbed. -

I have searched several pages in the forum about oxalic acid and read a few different recipes for mixing up Oxalic acid. I have a 4 strand braid of unfinished veg tan that my kids dog decided to mark as his. I have the crystals I just need to know how much to mix into water to make a cleaner for leather stains. I've seen add 1/4 cup to 1 quart water, 1 teaspoon to a pint of water, even make a paste for tough stains. Can someone tell me what is the best mixture to use for cleaning stains from leather and just cleaning leather? Thanks

-

Tool first before you glue together. Neetsfoot oil after its been cased and tooled. Herman Oak is good leather. The only time to oil first is when the leather is really dried out. You oil after to replenish the oils removed by casing and tooling. I stitch 1/8th to 1/4 from the edge depending on my tooling border. I tend to antique the tooling to make it stand out so I do 2 coats of 50/50 resolene then antique, then 1 coat 50/50 resolene then finish with Fiebings Leather Balm w/atom wax or a mixture of carnuba wax, bees wax and neetsfoot oil. Rub in with my fingers and a hair dryer to make it soak the waxs in. Then buff. To be honest I use the leather balm and atom wax more than the homemade carnuba/bees wax. It's just easier. Its like most times I machine sew the belt but if I really want to do it the best, I saddle stitch it. The home made finish is just more hand made effort. Reserved for those people I want to do something real special for. This belt was tooled with a 1/4" border and the stitch line against the tooled border. its a 1.5" belt. dont make the mistake I did. Make sure you leave the border at the tip of the billet so it does not look like you took a length of tooled strap and cut it off to make a belt. It looks better to have the border around the tip. This is wrong This is the better way to do it.. That belt finally finished with a stitch line at 1/8"

-

On the buckle I stop the liner layer so I am at one layer thickness 3 inches before the fold. This way the folded back part is the equal in thickness to the width of the belt. I end up with 6.25 inches of single layer leather before I fold it back at the slot. On the billet end I skive it down to a single layer about 2 inches back from the inner most hole.

-

I would have stopped buying from them a long time ago if they have been getting worse each order. Buy from somewhere that treats its $20.00 customers the same as their $500.00 customers. Is Springfield has what you need they are your best bet. If they dont carry what you want there were 2 other suggestions near the top of this thread

-

Lining Holsters And Gun Belts

mlapaglia replied to Johnny Valentine's topic in Gun Holsters, Rifle Slings and Knife Sheathes

For a gun belt you want at least 1/4" thickness to support the weight. Two pieces of 8/9 (16/18) makes a good 1/4" belt so 2/3 lining of a 12/13 (14/16) is about the same thickness. Now this is talking regular 1.5" width work/dress belt. You need the thickness to support the gun and the mags and your pants. For a cowboy type gun belt you want to use at least 9/10 for most designs. Belt loops are often done with 3/4 calf. Supporting all the weight of the gun and its position you need strong belts. Springfield will sell you shoulders, backs, bends or sides of Herman Oak. The tannery just sells by the side as far as I know but non of us can afford to purchase the minimum # of sides from Herman Oak. At least I cant. Lobo and a few others I am sure could. Double shoulders are good for holsters and belts for normal size people. Backs are good for belts for us larger folks. Just about anything but the neck area and the belly is good for holsters, belts, sheaths, etc. Michael -

Ll Vs Lr Needles , Stitch Patterns ...

mlapaglia replied to CustomDoug's topic in Leather Sewing Machines

I use a "S" needle 794 S 200 for my 277 thread. Gives me a great straight stitch line. Looks much better than the LL or the LR -

Small Satchel Pattern

mlapaglia replied to renegadelizard's topic in Satchels, Luggage and Briefcases

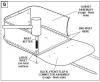

One warning on a container like this. Make sure that the firearm is secured in the case. You don't want it going off because the trigger got caught in the flashlight and was tripped on a big bump. Sew a holster inside of the case so that it is secure at all times. Id even use a retention strap with a thumb snap. This is one way to attach the back or front the the sides. The sides and bottom are one piece. You sew the edges together first on the back and they the front. The pattern is for a saddle bag. You could so the side piece as one piece without the reinforcement shown on this pattern. Its just shown so you can see the concept. This bag was laced not sewn. For the size you need I doubt you would need the rivets. Just saddle stitch or machine stitch it. -

Iwb With Clip Questions

mlapaglia replied to IngleGunLeather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Leather will remain just has it always has. Want the best in a car seat? you get leather. Want a great and classic couch, people get leather. A jacket that speaks for it's self, leather again. Kydex will suit those that buy off the rack. Those that want something that meets their needs and wants will still go for leather. I can see it existing along side of leather for a while but it will never replace leather as the holster material of choice. As for reholstering. I originally made my IWBs without a reenforcement piece to hold it open. My feeling that a regular person would not need to re-holster normally. Boy was I wrong. First time I wore mine out for the day I had to take it out of the holster 3 times. Once to adjust the holster and twice due to places that did not allow hand guns. I learned quickly that the ability to re-holster one handed was not just for tactical situations. From that point on all my IWB holsters have the ability to re-holster one handed. That's my opinion anyway. -

Iwb With Clip Questions

mlapaglia replied to IngleGunLeather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I agree about the over kill but in my opinion they just look better on a black holster. -

Iwb With Clip Questions

mlapaglia replied to IngleGunLeather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

If you are good at them copper rivets hook great. But regular rivets are easier to set. Just make sure they are installed correctly. -

Iwb With Clip Questions

mlapaglia replied to IngleGunLeather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I use 4/5 oz for the cover piece I put the clip in Rivet the clip to the cover and sew the cover to the holster. No metal to metal and the clip holds tight to a 1/4" gun belt. If making a tuckable IWB I use 2 pieces of 4/5 to make a pocket and just sew the end of the pocket to the holster. The long sides of the pocket are sewn together with only the end attached to the front of the holster. If you have any concerns about the holding power of the clip look at this one. It's a little longer but strong enough to hold a full size 1911 on a belt. -

Just make sure you use a clip that wraps around the belt and under the belt. If it is an open ended clip that could happen but the ones I use has an end that goes under the best leather and presses up against the back of the clip. This is the one I use. It is also available from Springfield leather. If you are at all concerned or using a full size weapon I would use this clip. It required a little slot in the leather down near the rivet but you will not pull it off the belt without lifting the clip. Both are good. The smaller one is best for compacts and sub-compacts. The large for Full size firearms. M

-

Buff it more, Currently its too thick. If you can feel it tacky then you need to take some more off. Better than Turpentine would be neatsfoot oil. 50/50 with the bees wax. I use 2 parts, by weight, of neatsfoot oil, 1 part bees wax and 1 part carnuba wax. The carnuba wax is harder and not as tacky as the bees wax. Rub it in well with a hair dryer and then buff it and buff it and buff it. Does a great job as a finish and as long as you dont get crazy with too much its not sticky at all. Michael

-

Start with 277. Its a good all around thread. I only use 346 when I really want the thread to stand out. I have 8 bobbins and thats enough for me. I have all the presser feet. I use the left zipper as my normal foot. The right zipper when I need it and the center presser when I need to get in somewhere tight. The center foot is one that you will not use ofter but when you need it you really need it. I have a goose neck lamp I use to light up the area. 12.00 at walmart. As for needles I use a 794 S 200 as my standard needle. It makes a nice straight looking stitch with none of the angled look some of the other needles make. Needles are cheap get an assortment and try them. Don't skimp on bobbins. If you don't have enough you will be wasting thread as you unroll one to fill with another thread. I have the material guide and it comes in handy on holsters and belts. Not essential but its a good part to have. I do not have the flat bed.

-

1 Which cut of leather and what weight should I get? A double shoulder or a complete side? Which of these pieces would ya'll recommend? http://springfieldle...oling-Leathers/ and what oz.? I want a big piece of leather because I'll be making a couple of cowboy rigs too. I Would get a double shoulder for holsters. But a full side gives you a lot of leather if you want to do belts for larger people . I use 8/9 for holsters and 2 pieces of 8/9 for belts. 2 What about horse butts? I've read that's good for holsters and belts but I only see small pieces from Springfield. I havent used horse yet so I can not answer this one. What size thread for holsters? #277 or #346? I'll also be stitching a matching belt to use with it. I use 277 with a 794 S 200/25 needle for my Boss Tippman. I have a XD .40 Sub Compact and want an outside waistband, higher ride for better concealment. What holster design would you guys recommend? I would suggest an Avenger holster or go with an IWB so it really wont show. Hope that helps.

-

Ouch. That is bad. You could replace the entire piece or make a piece that would cover the cracked section. Tool it up nice so it fits with the rest of the purse. Your other option is to deglaze the entire piece and redye it so the dye gets in the cracks. The best option I know of is to replace that panel. Hopefully someone will have a better idea. If it was my product I'd cut the flap off before the. Bend and sew a new piece to the back. Maybe do a decorative cut on the edge so it looked good and dyed it like the rest. Problem is if it looks like carp the you have to replace the entire piece. We all have things in the scrap box that still hurt to look at. I have a holster that was almost done and I noticed I had forgotten to sew a clip holder in place. No way to fix it but start over. 3 hours and a great piece of leather shot to heck. If that is a Tandy kit take it back and get them to rea e the leather if you purchased It reciently.

-

I only suggest oiling before tooling when the leather is REALLY old and REALLY dry. Normally its done after tooling and before dying. If you wet lightly before you bend you should have no problem. The point is to do it before you dye and finish. This way the leather is all stretched and ready for its normal posistion. I ofter do any bending right after the tooling while the leather is still cased. That way it does not have to be wet again. It all depends on how you want to do it. Just remember that one of the last things you normally do with a project is dye and finish. Burnishing the edges is in that part too.

-

Lightly spraying the flesh side along the bend line normally does not affect the finish as you are not getting it that wet. Sounds the biggest mistake was not making the bend before the finish. Its always best to make sure all the bends and fits work correctly before applying the finish. I personally think mink oil is for squeaky minks and not leather but that is a personal opinion. Other people love it. Can we see a picture of how bad it cracked? maybe there is a fix.

-

After tooling its always a good idea to oil the leather to replenish the oils that are removed by casing and tooling. Olive oil of Neetsfoot oil are some of the best things to use. Lexol is also a good choice. The Leather balm with atom wax really isnt any good to replenish the leather and keep it soft and supple. It is also a good idea to set the main bend area with the leather damp so it can stretch rather than crack. Did the leather crack or was it the finish that cracked? Resolene can crack if its on too thick. If it was the leather than even old dry leather will be usable if you treat it with neetsfoot oil or olive oil before you bend it. On old leather I treat it with neetsfoot oil, then tool it and then give it another coat of neetsfoot oil before I start with the dye and finish. If you do not want to darken the leather than use olive oil or Lexol conditioner. Neither will darken the leather as much as neetsfoot oil. What was the purpose of the Mink oil paste?

-

.357 Holster

mlapaglia replied to Sir Titus's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Its a good start. Have you finished with the beveling and background work?