AndreasB

Members-

Posts

32 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by AndreasB

-

@HideDesignsYes they are

-

Hi, I’m selling a set of 5 hand tools from Horseshoe Brand. Push Beveler makes a beautiful smooth burnished edge on one side of cut. Double Beveler allowing you to bevel both sides of a swivel cut for instance. Beader Blade wish leaves a burnished round topped line after it is used Creaser #1- creates a burnished edge along an edge- pattern is .09 width Creaser #2- creates a burnished edge along an edge- pattern is .120 width The set currently retails for $175 plus taxes and shipping. I’ll sell it for $100 including shipping within the US. I’m accepting PayPal, Apple Pay and Zelle. Andreas

-

Hi, I’m selling two edgers from Ron’s Tools that are barely used. They each come with the original sharpening rod. #2 Round Edger #2 Montana Edger Price is $80 each or $150 for both, shipping within the US is included. I’m accepting PayPal, Apple Pay or Zelle. Andreas

-

Sorry, both edgers sold together for $130, shipping within US included.

-

I have two Ron’s edgers for sale. Both were used less than a handful of times. Both come with the original sharpening rod. Round edger #2 1/16 cutting edge $80, shipping within US included. Montana edger #2 1/32 cutting edge $60, shipping within US included. Both edgers $150, shipping within US included.

-

The bottom stitch on my Cobra Class 4 looks very similar. I bought it used, so I don't know if it is supposed to look different when everything is adjusted the right way. I found out, that I do end up with a nicer bottom stitch, when I add a stitch groove before sewing. It seems like the stitch groove guides the thread and allows it to sit more evenly. But the top still looks much better than the bottom.

-

Thanks, I’ll head to Lowe’s later today to check on that.

-

Hi guys, what’s the official name of those things in the picture and where can you buy them? A Chicago screw will screw into it but you bury the part between two layers of leather. Thanks

-

This item sold. Thank you.

-

Used Craftool Deluxe manual leather splitter with 6” blade. Can be used for splitting or skiving. $220 shipped within the US.

-

Thanks everybody for the suggestions. I'm concerned about removing the adhesive, so I think I will go with the inlay solution.

-

Hi, I'm clueless on how to proceed. A while ago I got asked to build two rifle scabbards as a price for a local SASS match later this month. I'm ok with the scabbard build. The idea was to add an engraved plaque (2"x5") to the side of it with a certain text. We were talking a brass plaque all the time, so I planned on using glue and rivets to attach it. The guys from the gunclub had ordered the plaque and it came in yesterday. To my surprise it is not brass but brass colored plastic. It has an adhesive backer so I think it is the standard plaque that usually goes on the wooden base of a trophy. Now I'm scared of using rivets, because the plastic might break while pressing the rivets. The adhesive backer also prevents me from using a contact cement which I would trust more than what is on there at the moment. Since there will be flex and movement in the leather I'm also afraid that the edges of the plaque will come undone over time. First I was thinking of attaching the plaque by putting a braiding around the edge. But I've never done that before and want it to look good. Unfortunately I also don't have a spare piece of that plastic to do some testing with either glue, rivets... Does anyone of you have an idea what I could do to attach it? Thanks Andreas

-

He has. I had contacted him on the phone number he provided. He told me he can’t log into the site anymore so this post hasn’t been updated.

-

Bulk Dyeing of Edges with a Heritage Dye Box

AndreasB replied to nycnycdesign's topic in Leather Machinery

There is currently one for sale here: If you are not interested in buying used, the seller might at least give you his impressions. -

Their Facebook says that they are on their way to the show in Prescott and shop hours are only 1pm-5pm this week.

-

Hi blue62, were you able to obtain information about the 8020? I'm also interested in getting some info to determine if I want to buy one. Thanks Andreas

-

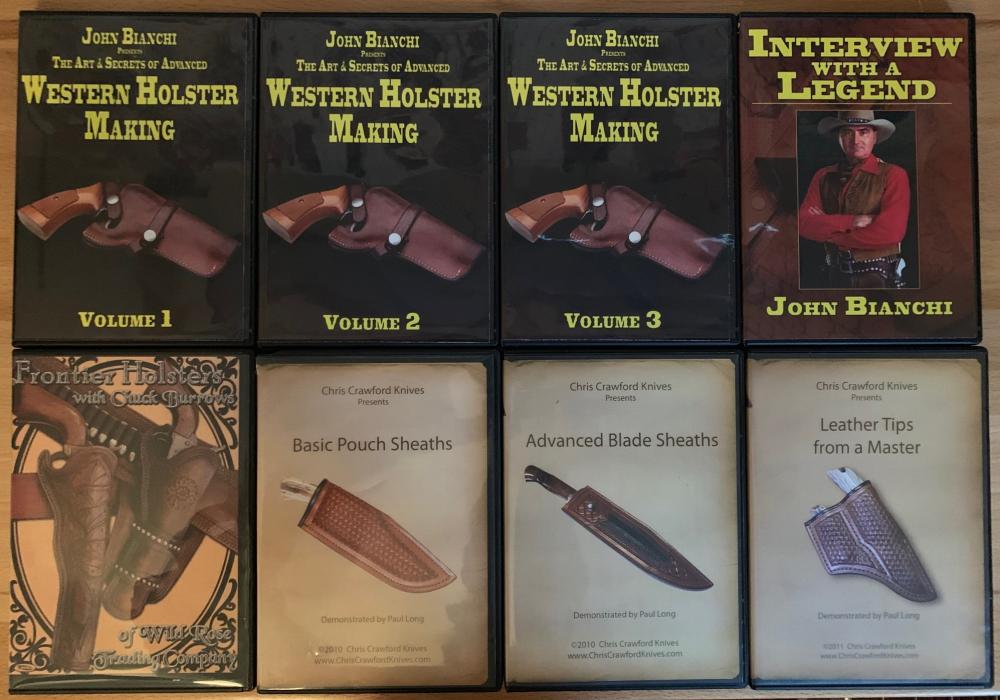

Hi, I would like to part with some of my DVD's. John Bianchi - The Art and Secrets of Advanced Western Holster Making 4 DVD set $80 Frontier Holsters with Chuck Burrows $35 Paul Long - Basic Pouch Sheaths $35 Paul Long - Advanced Blade Sheaths $35 Paul Long - Leather Tips from a Master $35 All three Paul Long as a set for $100. Prices include shipping within the US. Payment by PayPal only. Thanks Andreas

-

Hi everyone, I would like to make a leather bookmark with a nice carving. It will be my first sheridan project. I got a pattern already so I'm ready to go. Since the bookmark should be as thin as possible to not mess with the book I would like to know if there's a minimum thickness for the leather you would recommend so it is still ok to tool and carve. Thanks Andreas

-

Hi catsass, thanks for the advice. It seems like I'm using too much water to burnish the edges. Next time I'll try less. What I figured out is that if I don't wait long enough after dying the water changes the color more. But even if I wait 24 hours it still changes the color and doesn't go back to its original color. There's only a slight difference but it's still there. The problem here is that I only want to wetform part of my project and then it's quite obvious to see the difference. Maybe I would have to apply the moisture to the whole project in order to get an even color. That's some nice leatherwork you posted here. I'm far away from such perfection but I'm trying to improve my work. I've read that some people wet the leather or apply oil to it before dying. In my projects I recognized that if parts of the leather are still damp the color after dying is different to the dry areas. Is this something you would recommend and if so how much moisture should I apply?

-

Hi Jimbob, thanks for the advice. I tried cutting the circles with a really sharp cutter similar to the one you described and a rotary knife. The problem is when I try to cut the leather at once I need to apply a lot of force to the knife resulting in less control. And if I cut it in several runs the corner doesn't look nice. Also I tried it on my belt grinder but I would need a smaller wheel in order to get into the corners. Sanding by hand didn't work out great either. Tree Reaper, this seems to be a gizmo that might help. I need to find out if I can get a similar one in Germany Thanks guys.

-

Hi all, I got another question for you guys. I'd like to make some key fobs. I wanted to cut a figure 8 kind of piece of leather glue them together, stitch, dye... I tried to cut the leather a couple of times but it didn't really work out nice. Also it's not really possible to sand the edges on the now remaining circle nicely so I wanted to improve my cutting result in order to not need to sand. But like I said it didn't get much better. Any advice? I thought of getting a huge round punch an cut part of the circle away so I only have about 7/8 of the circle left and use this to punch my 8. Would that work? Thanks Andreas