bigsig11010

Members-

Posts

93 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Alabama

-

Interests

shooting, designing and crafting leather holsters knife sheaths and general leather goods.

LW Info

-

Leatherwork Specialty

None

-

Interested in learning about

custom pistol holsters knife sheaths etc

-

How did you find leatherworker.net?

google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

bigsig11010's Achievements

Member (2/4)

-

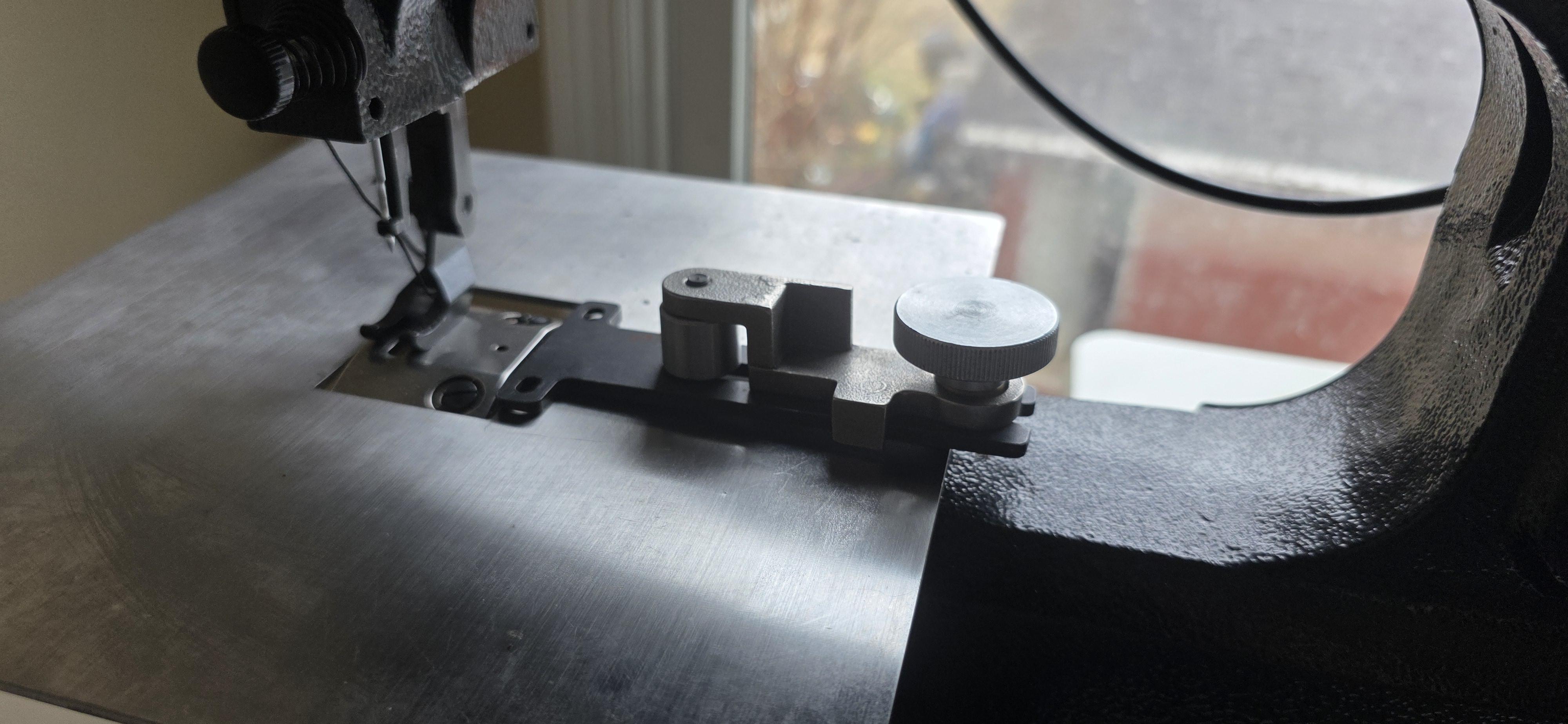

I have the steel flat plate on my Cowboy Outlaw. I also have the edge guide. When the flat bed is installed it makes the edge guide tilted to one side. My question then is are these two supposed to work together or are they mutually exclusive? Any help and guidance greatly appreciated. Pics attached i hope

-

Thank you sorry if I posted in wrong section.

-

Ohhh ok. Thanks

-

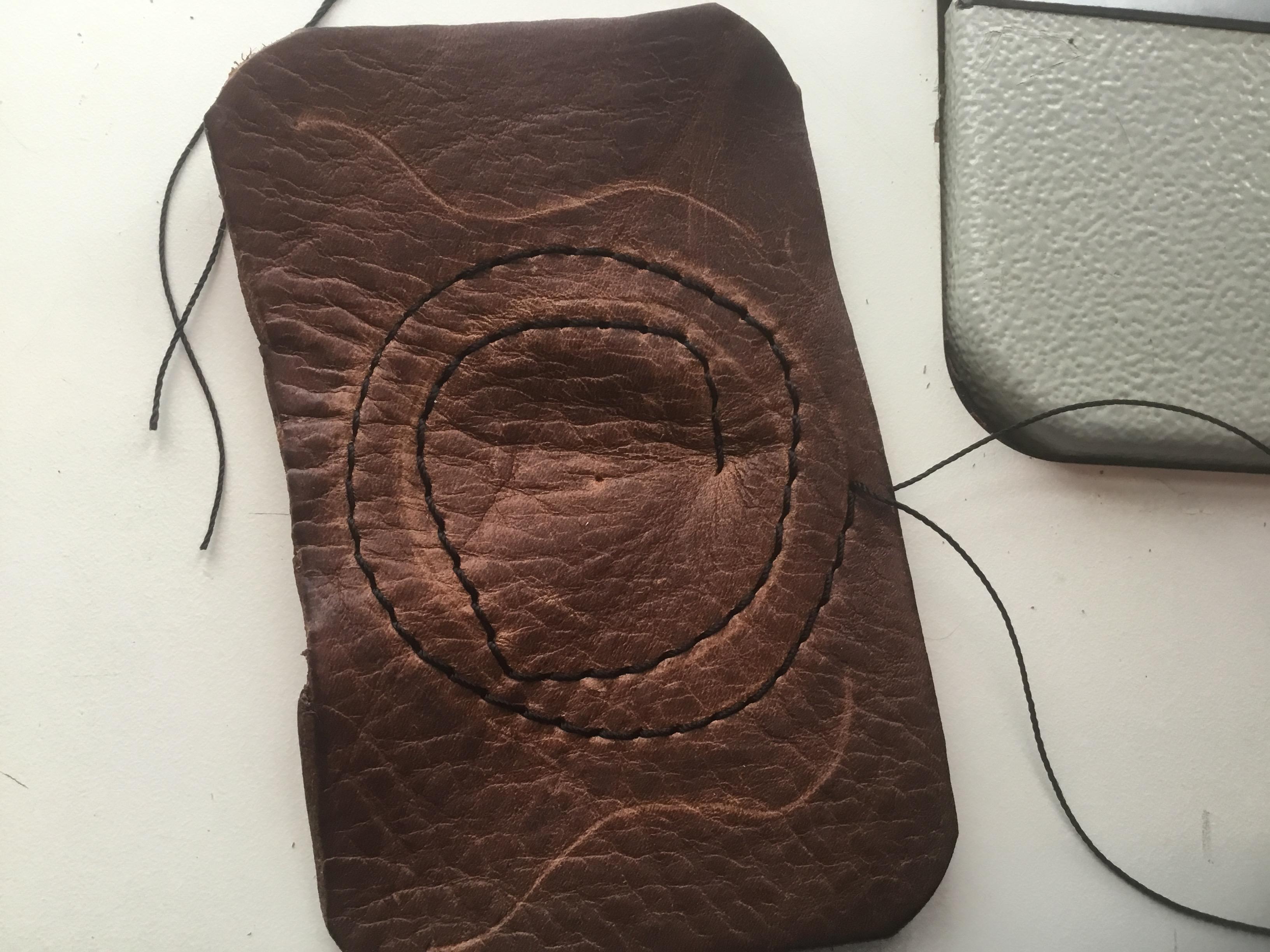

Just got my new set of steep angle smooth bevlers from Barry King. When I compare to recent project with my textured craft tool bevel I can barely notice the bevels with the new steep angle. Am I using the steep angle bevel wrong or is this how it's supposed to look?

-

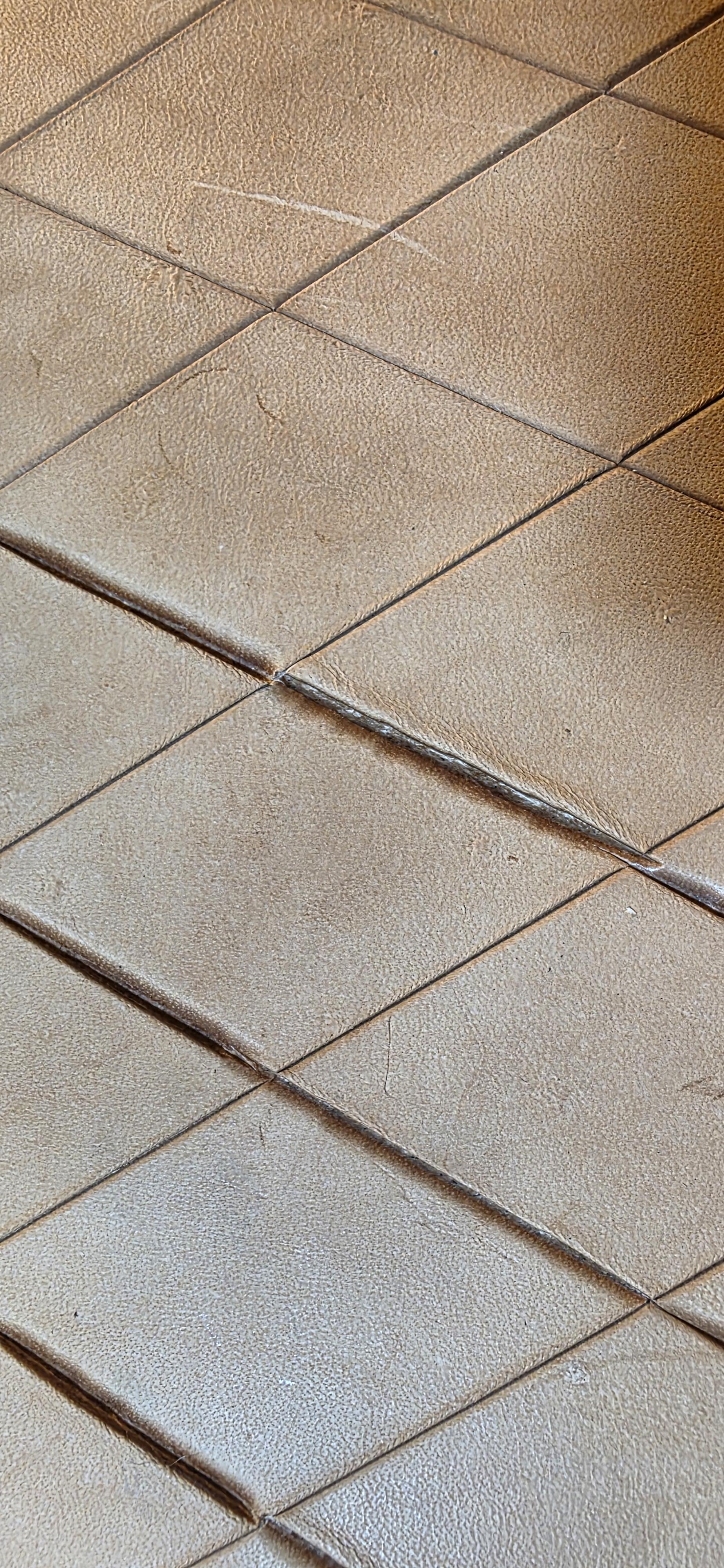

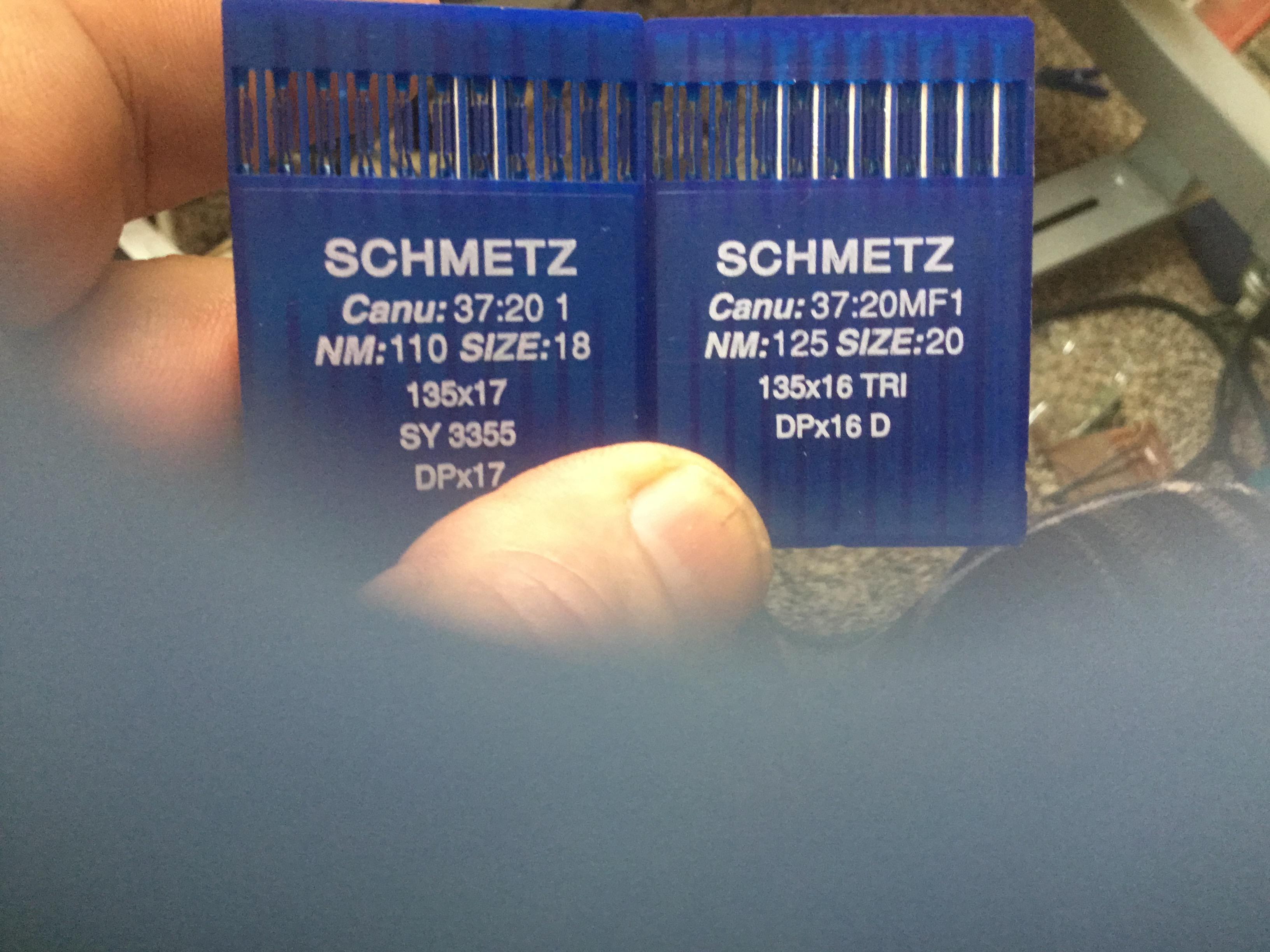

I rarely ever have any issues while stitching with my Outlaw but I had a problem with the bottom side of a curve and I dont understand what I did wrong. Im attaching pics. The top side looks ok. I can tell that I apparently altered my stitch length while navigating the curve but the bottom side looks like the thread skips across the corner on one side. Anyone have an idea what I did wrong and how to correct or avoid it? Thanks in advance. Bigs

-

-

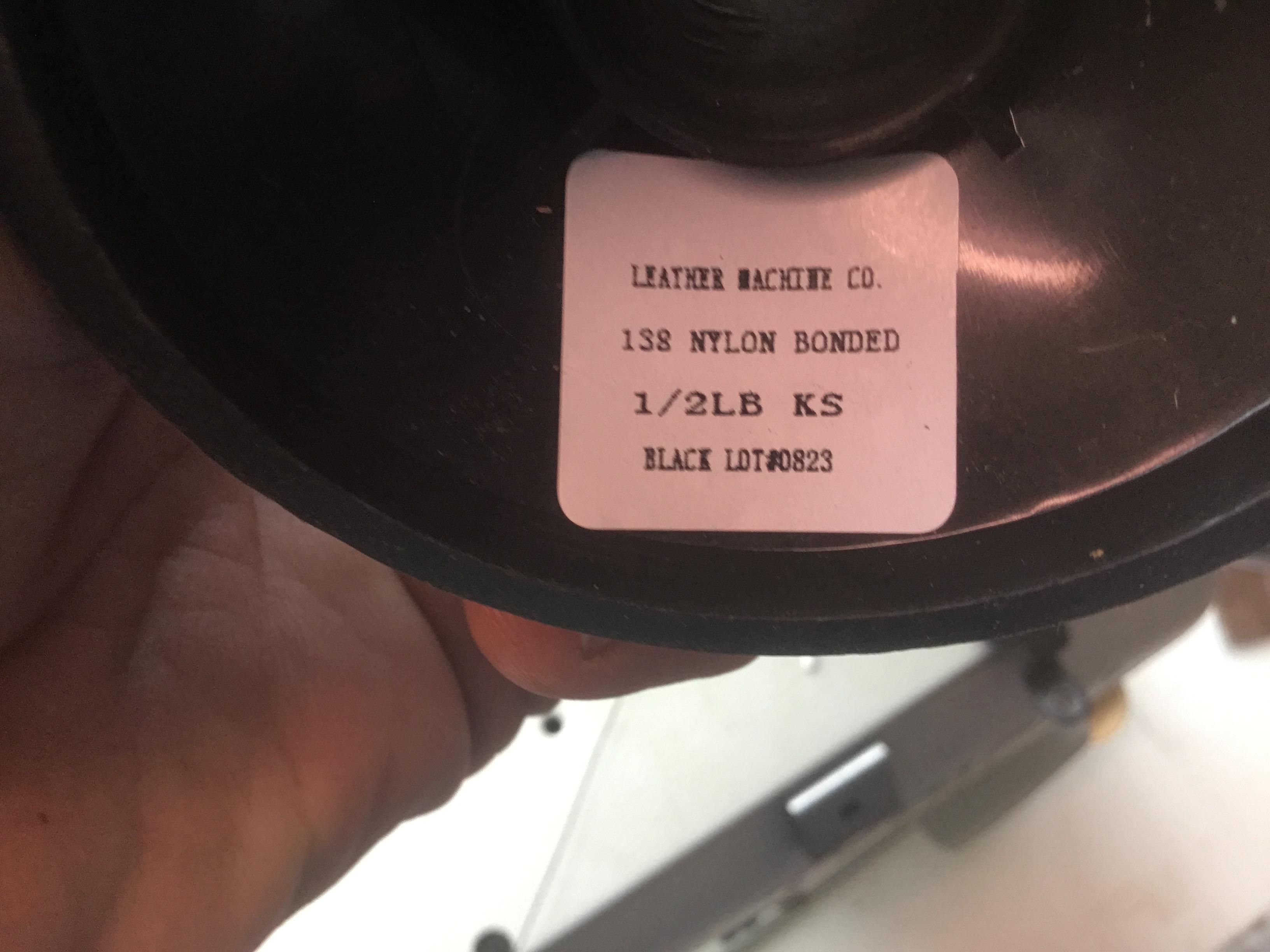

And here is my favorite machine. I try to make more heavier projects because I can do them with my outlaw.

-

Here is the other electric machine that I have. Im guessing the answer is the same for this one as I think it's triple feed which is what makes it not a fit for a roller foot but I'll ask just in case.

-

Thanks Tommy. Never even thought about that.

-

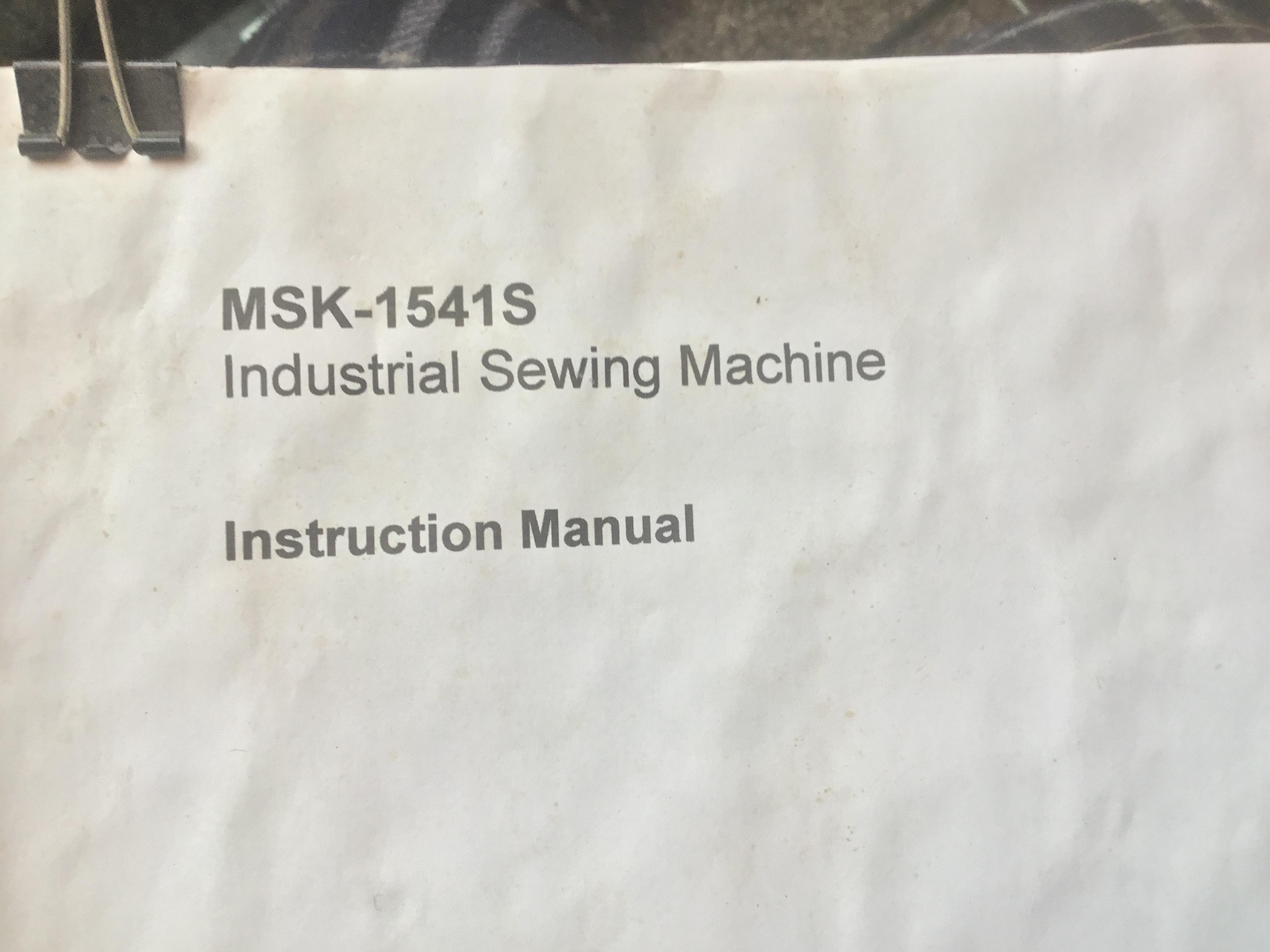

I believe Wiz answered my question and thank you for that. But I will try to upload some pics of my set up and also the first machine I bought which is sitting idle since I bought the clone. It’s a 1541S clone according to the paperwork I was provided. I also have a Cowboy outlaw that I use for heavier and multi layer projects.

-

CI have a Juki clone machine with basic walking foot set up. I watch too much you tube and I keep seeing people using a roller foot on leather projects. One area I really struggle with is curves and turns on my machine. I have a servo motor and changed pully which slowed it down considerably but I still am terrible on corners and turns. What would be the pros and cons of switching to a roller foot and then small or large roller? Thanks in advance.

-

I’m making a wet molded pouch that is more or less square. I’ve got the form and the leather is in the shape I want but the corners are wonky. I’ve tried to search you tube but the videos I’ve found are for flat corners or gussets. There should be a way to make a cut that will result in a more square corner but I can’t figure it out. Project is the mid pouch on the back outside of a scout carry sheath where you would carry altoids tin or brass tinder box etc. Thanks to anyone who can assist. Bigs

-

Juki 1541 clone speed reducer issue

bigsig11010 replied to bigsig11010's topic in Leather Sewing Machines

Ahhhh. Thank you so much!! -

I have the outlaw and have been using it for a couple years. I really like it. I haven't found any negatives so far. Built like a tank. Simple to operate even for me.

-

Juki 1541 clone speed reducer issue

bigsig11010 replied to bigsig11010's topic in Leather Sewing Machines

Ok let's try this.