-

Posts

175 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by cmantz

-

Thanks Josh...found a Tandy video showing the copper rivets and burrs (so know I know what a burr is ) Do you set these by hand (as they show in the video)?

-

Huge Difference In Horse Butt Weights?

cmantz replied to George B's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I have been using horse butts for some of my lasered nosebands and I have yet to receive any of the thicker leather. Mine all is the 5-7 oz. range and I find the same as you, inconsistencies within the pieces. Ihaven't measured mine for thickness but some are pretty thin. I figured it was the nature of the beast since these pieces are the fall offs. I would love to find some thicker also....so anxious to see if someone chimes in with a supplier. Chris -

It never occurred to me to sew these. All of the tack I have seen, or at last all of the tack that I have looked at recently, had rivets...and this includes high end tack (or at least high end to me at $500 a set). Here are some pictures So, you would recommend sewing these? They seem pretty narrow to me to be able to get enough stitches in there to hold them well. Also, not sure how to logistically get the machine in some of the areas...especially in the first image with the keeper. I will ask when I call to order hardware what is the most popular size. Thanks....at least I know to stay away from double sided rivets

-

I had to see 8 nosebands tonight on the new Toro 3000 that I picked up this pat weekend. It went pretty well for my first time but I did notice on one noseband I had an area with a few skipped stitches. What would cause that? It only happened on one noseband. Thanks Chris

-

All the sets I have seen have rivets where the buckles are attached (tug straps on breastcollar, throat strap on headstall, cheeks on headstall) How else would you secure the buckles?

-

I am going to attempt my first tack set. I have nothing as far as hardware is concerned. So, going through the Weaver catalog making up a list of stuff I need to order. I have buckles, d-rings, and my center ring picked out for the breast collar. Now...what do I need as far as rivets? I am assuming these are pretty standard. What is the difference between the "Jiffy" rivet and the "tubular" rivet? Do I want a double cap rivet? What is the best choice if I have to set these rivets by hand? I am getting a spot/rivet setter but for now I will just do these by hand. What sizes should I have in stock? What about chicago screws? Or would rivets be better? What size hole punch would I need to pre-punch these holes? And lastly snaps...oh my, so many different choices? which swivel snaps do I want? Thanks in advance.. Chris

-

Suggestions - Breast Collar D Attaching

cmantz replied to Wild Dog's topic in Saddle and Tack Accessory Items

I am getting ready to attempt my first tack set... Questions for you: what type/weight leather did you use for this? I think I am going to make a 2 ply breast collar and wonder if it is better to two pieces that are the same weight of if you could use a heavier weight for the front and a lighter weight for the lining. I am also going to do an overlay with spots...but probably use hair-on hide. I am assuming you just glued your overlay and then spotted. I have seen some sets that have stitched around the overlay before they added the spots. I wonder if that is necessary? What kind of spot setter do you have? Looking to make a decision on one this week. Setting spots by hand is definitely not my thing! Off to do some research on hardware for my new project.. Thanks Chris BTW...looks great your first one. LOVE the look! -

Just Getting Started - Bronc Halters

cmantz replied to cmantz's topic in Saddle & Tack Maker Gallery

I just saw that you asked a question...and I never answered. I am sorry. It was not intentional. There are tabs on the nosebands that I either fold back or forward and I attach them to the halters with the conchos. This way customers can change them out if need be or they can just buy the noseband and put them on their own halter. I have seen them with tabs that are folded to the front and sewn to the noseband. -

very nice job! I wouldn't know where to start and I have sewn all my life

-

Wow...thank you so much for the kind words. I am glad someone thinks so. I entered the "Dinky" halter in the Springfield Leather contest and didn't even get Top 10 ...but from the looks of the ones they did select for the top 10, they must have put more emphasis on the hand tooled/carved halters....and I get that. Someone that has been doing leather for many, many years may look at my halters as "cheating" since they are lasered. I know the true craftsman may not want to embrace technology. But on the other hand, don't have a problem with it. LOL Again, thank you so much!

- 2 comments

-

- bronc halter

- painted

-

(and 1 more)

Tagged with:

-

For Horse People: One Ear Headstalls - Advice, Please

cmantz replied to HorsehairBraider's topic in Braiding

definitely separate in case she every needs to adjust for a different horse. -

I have a Universal 30 watt laser (12"x24" bed). Go to my profile and you can see the images I uploaded of some of the items we have lasered. I am just starting out with the leather...be doing this about a month...so still learning. We have had the laser for 7-8 years and primarily use it for awards, plastics, signs...we also have a sandblaster (for wine bottles, glass, stone, etc) so he uses the laser to create the mask for the sandblaster. We also do some delrin stamps and acrylic templates. I may pick your brain when I start my first breast collar. I need to figure out what I need as far as hardware. Where is the best place to get those (considering I don't want to buy it lots right off the bat)? What size rings, buckles, etc. Do I cut the straps that attached the breast collar to the saddle or do you buy those precut? I don't have a strap cutter so what is the best way to cut straps? How to attach buckles and rings? Do I need to use rivets? Chris

- 6 replies

-

- breast collar

- sting ray

-

(and 1 more)

Tagged with:

-

see this topic http://leatherworker.net/forum/index.php?showtopic=27217 you will see a picture for an adjustable spot tool. This is what i use. Or you can use an exacto knife to make small slits in your leather.

-

I think it looks GREAT!!! Isn't it funny how we, as the makers, can look at something and see all the flaws but yet others look at it and think it looks perfect? I can't see any "glitches"..that is for sure. I love. I have yet to tackle my first breast collar...but it is on the books as I finally got a sewing machine. Chris

- 6 replies

-

- breast collar

- sting ray

-

(and 1 more)

Tagged with:

-

I have the spot setter from Tandy and it is ok. Here is what I have done. I bought the adjustable awl. I work on one of the rubber mats. I mark my spots with the awl so that it doesn't go through the leather all the way. Place the spots in the slits..they are in about half way. Then use the spot setter you just posted to set them in the leather. Turn the leather over and push the prongs over by with nail set (like you would use to countersink small nails in trim work). You can then place the leather, upside down, in the little "tray" thing they provide, with the spot in the right size circle and then hammer the prongs flat as long as the spots aren't too close together. All this is a pain! And definitely not a way to make any money considering the amount of time it takes to do it. Just my opinion.

-

See that is what I am saying. It is upside down. The other spot setters load on the top and you put your work facing up so you can see where you are placing your spot. With this you would be working upside down...and in my opinion, that just won't work because you won't be able to see you work as the leather would have the finished side facing down. How do you know where your spots you are placing would be in relation to the other spots? Not practical and probably a waste of money. You would be better to set them by hand.

-

this is similar to the Little Wonder by Weaver. I wonder how much the dies are for it? I think Springfield Leather has something similar as well for about the same price. Oh...it looks like it is bottom loading. Not sure if I would like that as it would be impossible to see where you are putting the spots.

-

Uh..this was a PAIN!! I just the Angelus acrylics but I tried to put a white underbase on it to help the colors pop. Probably shouldn't have done that. It look 4 coats of paint to get decent coverage and honestly I am still not totally satisfied with it...especially the green, yellow, purple. The blue looks really good Colors are magenta, purple, yellow, lt green and lt blue. Finished with Angelus acrylic finish, Fiebings black antique paste and then two coats of Fiebings Leather Sheen.

- 3 comments

-

- bronc halter

- painted

-

(and 1 more)

Tagged with:

-

From the album: Bronc Halters

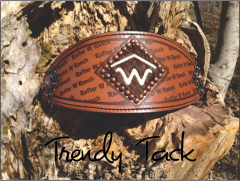

bronc halter with laser engraved background and embroidered hair-on hide ranch brand© TrendyTack 2013

-

- embroidered

- laser engraved

-

(and 1 more)

Tagged with:

-

- 3 comments

-

- bronc halter

- painted

-

(and 1 more)

Tagged with:

-

Did you get the 4 prong rims or the two? The ones I get are two prong rims so you can set the with an adjustable spot tool (do a google image search and you will see it). But I had to file the prongs down so they were narrower and didn't leave such a big slit in the leather and they work better. But I QUICKLY realized it is a pain to set these and in my opinion...not a way to make any money doing it by hand. Also, I ordered some rims and stones and tried to do them myself and again, it might be a little more expensive to order them put together but in the end I can't do it fast enough to save any money. My time with worth money and anything I can get to speed up the process and do it more efficiently will actually make me money in the end.

-

I am pretty sure most are done with rim set rhinestones. It seems like the rivets would be top expensive. They aren't fun to set by hand. I am looking at the spot setter made by Standard Rivet Co to set both spots and rim set rhinestones. It is a manual machine but a good price for entry level machine. Price is $595 and includes two dies...your choice of size. Rim set die was around $70. Weaver also makes one that is very similar As far as suppliers, I get mine from Dreamtime Creations. They make a "bling in a ring" and you can get any color stone set...either Swarovski or Preciosa. They don't do acrylics. You ca also buy the stones and rims seperately and set them yourself in the rim. Hope this helps. Chris

-

Spot Setter -- Standard Rivet Or Weaver?

cmantz replied to cmantz's topic in Hardware and Accessories

Thanks for the info on the sale. I didn't realize they were running a special. I will check it out tomorrow. -

I have talked to Bob as I was looking at a new Cowboy but then ran across this used machine. I will call him tomorrow. Not sure why I didn't think about him

-

I would like buy a spot setter. I am looking at the hand/foot machines from either Standard Rivet or Weaver. Does anyone have any recommendation on which is better? I know Standard comes with a 100% money back guarantee. Price is $595 and includes two dies of your choice. The one from Weaver is a little less expensive when you figure in the cost of the dies. Thanks Chris