-

Posts

70 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by BobW

-

Thick Veg Tan Watch Strap

BobW replied to BobW's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks Rohn! -

My watch is about 13 years old and the stainless strap was looking a little rough. I liked the looks of some of the the thick watch straps I've seen on the Internet so I decided to make one. It is made of three layers of 3-4 oz veg tan leather. I used a German made clasp. The orange thread is 277 poly.

-

Samsung S5 Phone Sleeve

BobW replied to BobW's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks guys! -

Samsung S5 Phone Sleeve

BobW replied to BobW's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks, Snubby! -

Samsung S5 Phone Sleeve

BobW replied to BobW's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks greighson! 3 to 4 oz leather is pretty thin, but I have three layers of it on the bottom half of the case. The combined thickness is 9 to 12 oz of leather! On the three layer edges I used a #3 edger and on the single and double layer edges I used a #2 edger. As far as the burnishing goes, if you haven't read Bob Park's pdf titled Finishing Edges, stop reading right now and go find it! When I started using his techniques and materials my leather working changed 1000%! Mr. Park uses Fiebings glycerin soap followed by Fiebings yellow saddle soap and finishes the edges up with plain old paraffin and a little Neat-Lac. He also recommends using heavy canvas as his primary contact in the burnishing process. Look for pictures of his work, the edges look like glass rods! My burnishing technique evolved from Mr. Park's choice of materials. My three step process is the same glycerin followed by saddle soap and finishing up with paraffin. I don't have a power burnisher to achieve the heat, which is a critical component. I use a combination of lots of elbow grease with the pad of my thumb, heavy canvas and a $1.50 wood burnisher I ordered from China. For the occasional "hair" that pops up I use 400 grit wet/dry sandpaper. I apply four or five coats each of the soaps, really packing it into the edge. At this point, I am tempted to stop because the edge is beautiful! Instead I apply three or four coats of paraffin. I skip the Neat-Lac. This gives the piece an edge that will age beautifully. I was not able to get the wax heated up enough initially to have it penetrate and flow into the leather. I was able to achieve this with the use of a small 100% wool disc cut from a saddle blanket attached to my Dremel. Now I apply a layer of paraffin and in a single pass with the Dremel on the lowest speed and it is melted in. After three or four application of paraffin I am done. Initially it has a satin appearance but after a couple days in my pocket it's shiny. When I started leather working a few years ago I wanted to make items that were good looking, last a life time and would be practical in everyday life. This simple case embodies those desires. I am not into anything that makes the leather smell like or appear to be made of vinyl or plastic. I've got a bottle of super shiny leather finisher and some gum trag that I will never use! This is probably more information than you wanted but you got me started! Thanks again, Bob -

Samsung S5 Phone Sleeve

BobW replied to BobW's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks Double, either I got lucky or I'm getting the hang of it. Bob -

-

-

Belt "dragon"

BobW replied to Tatyana's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice, Tatyana! Thank you for sharing. Bob -

Samsung S5 Phone Sleeve

BobW replied to BobW's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks Tony. The Tiger Thread is 1.0. I think the SPI is 8. Thanks Wild Bill! Thanks NS. The front was wet molded. Bob -

Great work as always, Rohn! I would never have thought to go for that color, but it looks good! Very unique! BobW

-

Samsung S5 Phone Sleeve

BobW replied to BobW's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks guys for the kind words. I'm happy with the way it turned out. Basically Bob, I did not use a mask, I simply used a fine line brush and a (mostly) steady hand around the knot. I applied the rest of the black dye with a rag. With a nearly dry rag I brushed lightly one time over the knot, catching the high spots. Thanks again, BobW -

Samsung S5 Phone Sleeve

BobW posted a topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I picked up a new phone on Black Friday. I made a new sleeve for it Saturday. It was made from 3-4oz veg tan leather. I put a celtic symbol on the front. The symbol was treated to medium brown gel antique and covered with acrylic finisher. I dyed the remainder of the exterior with Fiebing's black oil dye. It was stitched with light brown Tiger thread. The edges were burnished with glycerin then saddle soap and finished with parafin. I apply the parafin with a wool disc I made for my Dremel. This heats the parafin and the leather and allows penetration. The inside surfaces were treated with Tan Kote to make the phone slide easily. The exterior surfaces of the sleeve were treated with a home made beeswax based conditioner/protector. The combination of the conditioner and edge treatments leaves the sleeve with the smell of leather and a soft touch. -

Very nice work, Slip. I love seeing unique items made with an attention for detail. Instead of trying to match your bags to the honey colored saddle, try wet forming a new saddle cover on an old Brooks pan. Then dip-dye the veg tan leather for a consistent, even color that would match perfectly! You could even make matching handlebar wraps. Check out this link that is on MuddyClearWaters posts: www.carsonleh.com I didn't see any traditional Brooks saddles, but they are very imaginative! Thank you for sharing one of your passions to create, Bob

-

Thanks! It's ~5oz veg tan leather. Yes it was wet molded over the cellophane wrapped tablet. I have to thank Bob Park for his edging article (http://leatherworker.net/edging.htm) for the improvement in my burnishing. Saddle soap and canvas, simply genius, and without the use of expensive power tools or exotic wood slickers!

-

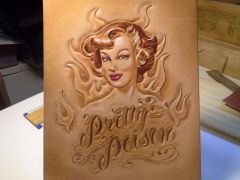

From the album: Newbie Practice Pieces

-

From the album: Newbie Practice Pieces

-

From the album: Newbie Practice Pieces

-

From the album: Newbie Practice Pieces

-

From the album: Newbie Practice Pieces

-

From the album: Newbie Practice Pieces

-

From the album: Newbie Practice Pieces