-

Posts

70 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by BobW

-

Matching Knife Sheath and Ranger Belt

BobW replied to snubbyfan's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice Snubby! The edges are impressive, as always! -

The Varangians Belt.

BobW replied to Samar's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice work, Samar! I absolutely love the wolf! -

Decided to make a phone sleeve out of something besides veg tan. I dug around in a remnant box and found some chrome tanned leather in a dark brown that is VERY supple. I was able to get the edges burnished despite everything I've read said that it can't be done. It was an interesting experiment! I think I will carry it for a while and see how the edges hold up.

-

Very nice work! Would love to hear more about how they were made and what materials you used. My wife asked me to make her a pair of leather flip-flops last year but I couldn't find enough information. Yours are exactly what she described! Thanks for sharing.

-

How much are you asking for this stamp? What about a 1" x 1/2" maker mark? Can you make stamps in brass?

-

Another Fishing Chair

BobW replied to wantedleatherworks's topic in Furniture: Inlays and Upholstery

Nice work! Are the straps stitched into the underside? If you don't mind me asking, how much are you getting for them?- 11 replies

-

Learning To Make Wallets

BobW replied to MonicaJacobson's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Monica, Nicely done! I especially like the contrast in texture and color between the exotic and the smooth leathers. I'm a little reluctant to offer advice on stitching. But what I will do is share with you the process that works for me. My first pieces done with a stitching chisel were awful! I've slowly got to the point I can keep the lines straight (nearly) all the time. The process that works for me is as follows: 1. I mark my stitch line with an scratch awl, making a fairly deep impression. 2. I mark stitch position in the grooves left by the awl with the chisel. I press the chisel down firmly by hand to leave a highly visible and tactile mark. 3. I align the stitch line away from me, not side to side, to better control the angle of the chisel. 4. I position the chisel by letting it fall into the the divots I left earlier. 5. From this point on, my focus is solely on keeping the chisel perfectly vertical. I don't look at the mallet, only at the chisel. I don't try to hammer it through with one blow. I use multiple light and then medium blows. I take my time to re-position the chisel after each rap of the mallet. 6. I don't use a stitch groove on the front but I do apply a light groove to the back after it is punched. An example of my stitching can be seen in my album that I just posted in the Gallery section. Thanks, Bob -

From the album: Samsung Note4 Pocket Phone Case

Lightly sanded, unfinished interior.-

- note4 veg tan

- phone

-

(and 1 more)

Tagged with:

-

From the album: Samsung Note4 Pocket Phone Case

Card pocket holds 1-5 cards-

- note4 veg tan

- phone

-

(and 1 more)

Tagged with:

-

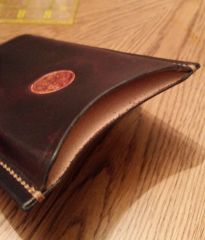

From the album: Samsung Note4 Pocket Phone Case

Nice saddle soap burnished edges finished with parafin-

- note4 veg tan

- phone

-

(and 1 more)

Tagged with:

-

From the album: Samsung Note4 Pocket Phone Case

Front from the top. Nice straight stitch lines, top and bottom.-

- note4 veg tan

- phone

-

(and 1 more)

Tagged with:

-

From the album: Samsung Note4 Pocket Phone Case

Front from the bottom. -

Ranger Belt Work In Progress

BobW replied to snubbyfan's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice, Snubby! -

A true work of art! Absolutely stunning!

-

First Motorcycle Seat Rebuild-Progress

BobW replied to Twisted 66's topic in Motorcycles and Biker Gear

I love the way the design, tooling and coloring turned out, it looks great! I can't wait to see it finished. Thanks for sharing. -

Biker Wallet

BobW replied to Boothill Bob's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Beautiful piece, Bob. Excellent basket weave! -

Valley Themed Wallet

BobW replied to frenchy07's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

You should be proud when you can take an idea from just a mental image to a reality ! I'm sure that is the way Van Gogh felt. Although, some of my leather pieces look more like they were made by Salvador Dali! When I first tried using a diamond stitch punch my stitch lines looked good on top and downright awful on the bottom. I found that making sure the punch is perfectly vertical made all the difference in the end. I think if you take your time while punching you won't have to use a stitch groove unless you want to countersink the thread. -

I woke up at 4am Christmas Eve morning with the horrible feeling I had forgotten someone's Christmas gift. After going through the pile of presents, I realized I hadn't made my daughters watchband as I had planned. By lunch time it was done and I could relax. It is made with two layers 3-4oz veg tanned leather dyed black on the top and left natural on the bottom. The edges were left unfinished. I used red 1.0 Ritza thread. This band is a replacement for the band on her Ed Hardy watch that she absolutely loves. I re-used the buckle from the old band as it was still in perfect condition. In order to get the stitching to "point" in opposite directions, I punched one side from the top and the other side from the bottom. I am fairly pleased with the way the stitching turned out. I am not so pleased with the stamped crosses. Oh well, she loves it and that's all that matters...I guess.

-

Zip Around Wallet

BobW replied to hockeykspiky's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice! Simplicity at its' best. Thanks for giving me something work toward. -

Thick Veg Tan Watch Strap

BobW replied to BobW's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

No secret, Michelle. I did hand stitch it and it is machine thread. The only problem I had with it was I had to re-tread the needle several times. I just applied more beeswax and went on. It was trying to unravel close to the needles but I had 8 or 10" extra on each end so it didn't effect the strap. I'm glad I didn't know ahead of time it wouldn't work, because I wouldn't have tried it! I guess ignorance is bliss! Bob -

Thick Veg Tan Watch Strap

BobW replied to BobW's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

No method, just madness! I still had to skive slightly for the watch pins but there was a LOT of skiving to get the clasp to fit. I have some Panarai style buckles coming which will work a lot better with the thick leather. I will probably finish it out to match my phone case with Havana Cigar stitching and the leather dyed black. Yes, I think having a watch first is a good idea! Bob "Well...it seemed like a good idea at the time!" -

Thick Veg Tan Watch Strap

BobW replied to BobW's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks Halitech. Given the thickness of the divers watch, I wanted a thick strap. The three layers of leather gave me that thickness. Keen eye, the thickness of the center layer is nearly identical to the diameter of the pin! Bob