-

Posts

961 -

Joined

-

Last visited

About BDAZ

- Birthday 02/02/1948

Contact Methods

-

Website URL

http://www.gsicreative.com

Profile Information

-

Gender

Male

-

Location

Tucson AZ

-

Interests

Old Time and Irish banjo, guitar, photography, shooting sports, sea kayaking, Scuba, endurance cycling, 3D Printing and Laser cutting and engraving

LW Info

-

Leatherwork Specialty

Instrument Straps and music related cases and products

-

Interested in learning about

Sheridan Carving

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

9,616 profile views

BDAZ's Achievements

Leatherworker (3/4)

-

I was able to successfully laminate the graphic to the vachetta. I skived the flap down around 50% using a belt sander and then washed the surface a few times with acetone and allowed it to dry before using thermal adhesive to to bond the fabric to the leather. I would never buy this leather again. Great for making Gucci bag clones.. Bob

-

The flap is around 6 inches wide and that's essentially what I had after the first failure. The heat activated adhesive holds until the leather is bent. Maybe I can find a sealer that would penetrate enough, after an acetone wash, that would block any additional incursion by the waxes. Bob It's the flesh side so it's not the texture, it's that the waxes impregnating the leather seem to return after a few days and break the bond. Thanks, Bob

-

I make cases for wind instruments. I use Wicket and Craig drum dyed veg tan for all my products. A current client has ordered 10 highly customized cases for export and one had to be red. I purchased a 1x2 panel of: Valdibrana Conceria, Tarano, Italian Vachetta Leather from the Buckle Guy: https://www.buckleguy.com/valdibrana-concerie-tarano-italian-vachetta-leather-panel-candy-apple-red/ I use HTV vinyl for some decoration on the grain side of the flap and the flap is laminated with a custom dye sublimation print on polyester fabric using a thermal adhesive sheet. I do something similar on all my Wickett and Craig products with no issue and have been doing so for years. The heat transfer worked perfectly on the grain side of the Valdibrana but after completing the case I folded the flap and there was absolutely NO adhesion on the flesh side, held in place only by the stitching. I had to disassemble the case and there was no trace of the adhesive on the flesh side of leather, it had completely adhered to the fabric. I realized there was probably some form of wax on the flesh side . I did some tests on scrap and used acetone to remove the wax. I tested lamination on scraps with the heat activated adhesive, Tandy Eco Flo, which I have found to be exceptional for demanding projects, and a few solvent based craft adhesives as well as Tanner's Bond. All seemed to adhere well to the acetone treated leather. I gave it 24 hours to cure and adhesion was good. I reassembled the case, laminated a new graphic (170 lbs @ 270F for 30 seconds) and adhesion seemed excellent. A few days later I returned to mount the hard ware and when I folded the flap it was clear that the adhesive had failed. I easily pulled up the fabric and injected a solvent based adhesive underneath and used a roller to spread the adhesive across the entire fabric covered area. I covered with a piece of flat granite with 10 lbs of additional weight and left for 24 hours to cure. The I left it uncovered for a few hours to allow the solvent to evaporate. The adhesion was minimal and immediately produce a failure at the fold. Does anyone have a suggestion of a flexible, bullet proof adhesive? Clearly the leather is loaded with waxes, especially the flesh side. I am willing to try any kind of adhesive, including construction adhesive. Plan C is to make another case and dye it red, but quite frankly, the finish of this Italian leather is fantastic..would not be out of place on a Gucci bag: https://poshmark.com/listing/Gucci-Soho-Red-Cellarius-GG-Logo-Leather-Chain-Tote-665df009d4b237570c0de87b?srsltid=AfmBOopRltHNRbM-wYsUmdGbLFBTBmDy9cWbp4lhx-eQ63TaTtKj24krs18&gQT=1#utm_source=gdm_unpaid Thanks! Bob

-

There are two reasons to sue for intellectual property infringement and AFAIK, this is a trade mark not an image, that can be or should be "circle C" I have to renew my trademarks every few years or risk losing them. The first reason is to prevent fiscal damage to the company by utilizing their trade mark on a copy or even counterfeit product. The second is the responsibility of the holder of intellectual property protection to prosecute any serious infractions or risk losing the protection. I wouldn't worry in the least! I did a quick search of Garmin trade marks and they hold over 7,000. Many are dead (abandoned) and ona quick search I couldn't find any any trademarks resembling your design.. Good luck! bob

-

There are a lot of different applications for this graphic, including municipal signs and other companies. There's better reasons to stay away from the US than Garmin!

-

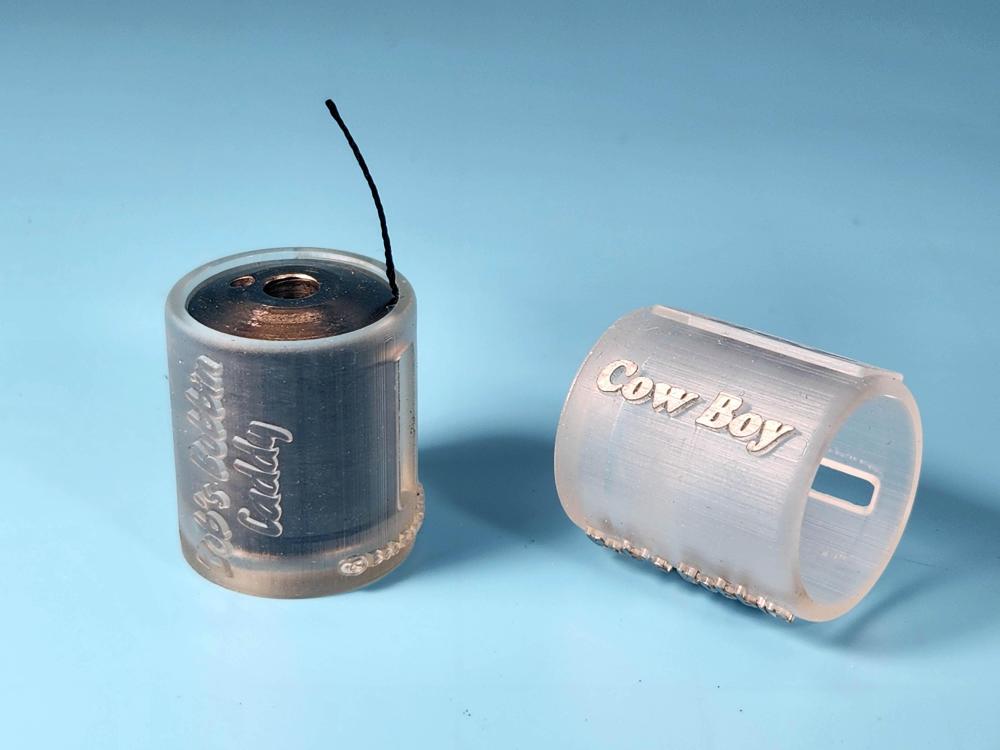

Here is the final version. There is a flat panel to write the thread weight with a Sharpie, transparent, so one can get an idea of the amount of thread on the bobbin, a slot to see the actual thread color, and the fit (at least on my bobbins) is snug enough to invert the caddy while retaining the bobbin in place. The resin is top of the line and should last for years. I have worked up pricing for folks on the forum: 6 Bob's Bobbin Caddys including packaging, USPS shipping and PayPal fees: $20 12 Bob's Bobbin Caddys including packaging, USPS shipping and PayPal fees: $30 Please PayPal to bob@sinkthestink.com (my day job: Gulf Stream International) Thanks for your interest! Bob Wiz: As promised, a box is on the way as a thank you for all the help I received from you when I was starting out!

-

Great. As soon as I have the first dozen finished, later tonight, I'll be able to work up shipping costs. Bob

-

Excellent! I have started printing Bob's Bobbin Caddy production versions made from transparent resin and with a slightly (.025mm) smaller for a snug fit. They have certainly cleaned up my thread drawer on my 3200 from the bird's nest it used to be. You can write on the flat panel with a sharpie with thread size, etc and remove it with IPA. Take care, Bob

-

Wonderful! That's where I got mine, 10 years ago! I have just received some transparent resin and I will do a test print tomorrow to make sure it works well and probably post the results tomorrow. At the same time I'll finalize the pricing. I'll work up a dozen price as well as singles. Thanks! Bob

-

Haven't a clue. These fit 23.77 x 30.36. Size is easily adjustable Bob

-

Yes indeed, using an 8K resin printer Pretty close. Just deciding on what color for the production run. Possibly white or yellow.

-

My 3200 is one of the best things I have ever bought. Hasn't dropped a stitch in 10 years. Mine must be an early one, as it doesn't even have a Cow Boy sticker! Somehow, it seems to work perfectly, even without one... I'll fire off a few of the final holders for you to have a look at. I am assuming they fit current spools..mine are all 10 years old as well. Bob

-

Nice but these are only for the bobbins. The larger spools are a different and simpler problem. I just use a wide rubber band.

-

I'm just doing some final tweaking so I have some extras. If you'd like to play with a couple and want to pay for postage (+-$5) let me know. Bob

-

Nor sure if anyone else will find these useful, but the drawer where I tossed my bobbins when changing thread, after filling, etc was a bird's nest of unravelling thread, broken rubber bands and unsticking painters tape. . I am sure there are other solutions, but these are prototypes that have made a huge difference in the sewing machine drawer. Not a nest to be fond now. I may add a textured flat panel to write thread info, and use white resin which will accept pencil marking. The spools are a snug but comfortable fit. Comments? Bob