DCKNIVES

Members-

Posts

696 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DCKNIVES

-

Where's The Quality In "custom" Gone

DCKNIVES replied to Chief31794's topic in Leatherwork Conversation

First ,I have to agree with rdb,discuss it but you don't have to pinpoint makers to ridicule.In this internet era, it only takes a short time to create a website to market your products and there are so many taking up leather and knives its crazy.Many have been at it a short time and start selling.As a 20 year veteran of making I have found that the market will weed out the ones not offering top quality, and reward those that strive to do quality work.As far as Paul Long and Sandy Morissey, Paul is a friend and has been doing leather work for about 40 years and almost exclusively sheaths for about 5.Sandy is a very dear friend and was and still is my mentor, he has been doing leatherwork for about 60 years and has produced about 30,000 sheaths in that time. Back to sheaths,alot of knifemakers don't like doing sheaths but see it as a necessary evil and attempt thier own, usually it shows.Many don't offer sheaths at all and will allow you to contact a sheathmaker and there are quite a few to chose from, some with a years time in others many years.Then are those that love both areas and try to excell at both.But I also think the word custom has become somewhat blurred .In my mind, custom means building something per the customer specs, not doing what you think is cool and selling it.That to me is simply handmade. Much of the stuff I make is straight off customer drawings, something much harder to do than most would think, but it usually results in repeat business. Pricing custom work is something most have troubles with especially when starting, and this is where most of those with lesser work get weeded out.Personally I don't think $95 for a sheath is high at all given the quality is ok, mine are generally higher sometimes much more depending on the job.Just a few thoughts.Dave -

Holster Liners ?

DCKNIVES replied to gearjammer711's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I do all my holsters the same as Mike above, with the exception being doing a requested period early Western holster.I also do inlays on about 99% of my holsters so lining is needed anyway.Dave -

Actually finding the steel is the easy part, there are quite a few places carrying knife blade steels.Here is where I shop alot Admiral Steel.A2 is a great steel, but being an air hardening steel and the fact it has a fairly narrow range of crtical temp makes it hard for the hobbiest to do without a good HT oven.Texas Knifemakers Supply will HT air hardening steels for you if you don't have a oven. Dave

-

Generally no, while there are some old saws that may make a reasonably good knife, it is still an unknown steel as many makers pick their own alloys.The ones with carbide teeth are mild steel and will not hold an edge,the same applies to circular saw blades.Your better off purchasing a known good quality steel with a proven track record and the ability to heat treat properly.1080,1084,1095, and O-1 come to mind, all good steels,reasonably priced and good edge holders when HT'ed properly.Dave

-

The Second 'new Holster'

DCKNIVES replied to katsass's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That one turned out super Mike.Love the inlay my friend.Dave -

Anyone In Orlando Want To Get A New Guy Started?

DCKNIVES replied to Calvin2's topic in Getting Started

Calvin,I'm a bit far, but I would suggest you go to the Tandy store in Winter Park and look around, ask questions and see if they know anybody or have classes and workshops.Dave here's the directions to the store Tandy store -

Luke, it used to be horse back several centuries ago now its refers to shark or in this case stingray. I use a belt sander to sand the back down and thin it.Dave

-

How To Do An Inlay Piece?

DCKNIVES replied to marine mp's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Mike,I have a small tutorial on my website listed under "Knife Info" that should get you started.You can also get your exotics from the Ostrich Market .I do holsters and sheaths for them, great folks to deal with.If you have any questions feel free to contact me.Dave -

Jake, try here for the Alligator back straps,Ostrich Market. I was over there last week and bought some.Talk to Henry or Jeanne and they will fix you right up.If you have never done an inlay I have a tutorial on my website under "knife info".If you have never worked with back straps, they can be a bear to work with.Be sure to have a Dremel tool handy for sanding the bumps that are covered, also the flesh side is usually rough and will need to be thinned and sanded.Dave

-

Casull 454 Rig

DCKNIVES replied to DCKNIVES's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Robert, a small sheath like that should take about half an hour.Basketweave lacing takes a bit of time, way more than some want to take but I like the look of it, and I do charge extra for it over stitching.I probably have about 6 hours of lacing on this holster.Dave -

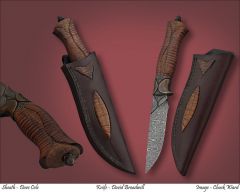

DC KNIVES and LEATHER

Images added to a gallery album owned by DCKNIVES in Our Leatherwork Galleries

-

From the album: DC KNIVES and LEATHER

© © leatherworker.net

-

From the album: DC KNIVES and LEATHER

© © leatherworker.net

-

From the album: DC KNIVES and LEATHER

© © leatherworker.net

-

From the album: DC KNIVES and LEATHER

© © leatherworker.net

-

From the album: DC KNIVES and LEATHER

© © leatherworker.net

-

Casull 454 Rig

DCKNIVES replied to DCKNIVES's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks everyone. Eaglestroker, I do have a tutorial on my website under"Knife Info".Dave -

Do you want real gator ?If so try here,Ostrich Market , I was there last week and he had a bunch.Great folks to deal with.Dave

-

Trophy Six Shooters

DCKNIVES replied to customcowboyleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Great looking belt,and the carving is really well done, but I have to ask why you ran your basketweave the same direction on both sides.Dave -

I'm sorry but I have absolutely no idea how to do a PDF file.Dave

-

Just finished this one.My 44SAA is used for the pics.Alligator inlay and overlay with basketweave lacing.Dave

-

Al Stohlman Brand Damascus Medium Round Knife

DCKNIVES replied to Phatdaddy's topic in Leatherwork Conversation

I know a couple of makers that bought them and they are pretty much junk.First ,That isn't true Damascus, I work with true damascus almost daily, and the real stuff will hold an edge as good as most quality steels, properly heat-treated.A good quality round knife needs a good known steel, properly HTed , hard to get a good one mass produced at that price.Dave -

Alligator And Leather

DCKNIVES replied to mmirob's topic in Gun Holsters, Rifle Slings and Knife Sheathes

It's smoother due to it being a belly cut, back cuts have all the horns and the problems of dealing with them.Bellies are much easier to work with, so naturally I get more requests for heavily horned back cuts.The holster is nicely done.Dave I get my Gator from here Ostrich Market -

I agree with Art, I also have a Baldor.I have been using it for about 20 years now with no problems.One thing you should know is the buffer is probably the most dangerous tool in most any shop, I hardly know any maker that couldn't tell you of at least one accident or close call with one, and if you don't hurt yourself you can easily damage your project.So a light touch ,clear head and alot of respect are in order.I would go with the slowest buffer you can find and use a soft flannel wheel.They grab more but don't build heat as quickly.I myself prefer to hand buff and use my buffer for knife handles,but I know makers that do thier leather on them but not many.Dave

-

As a knifemaker I can assure you there are No standard sizes, be it for length, thickness or height.They are all over the place,having said that, folders other than most slipjoints generally run between 3" on the small side to about 5"-6" on the large size.Since I am a custom maker,I usually have them send the knife to me, for a good fit. I also usually make open top sheaths so a little either way isn't going to be a problem.I also use a different design which will fit a larger number of knives.Dave