Landcruzer94

Members-

Posts

29 -

Joined

-

Last visited

Profile Information

-

Location

United States

LW Info

-

Leatherwork Specialty

Watch bands

-

Interested in learning about

Finish techniques

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

4,862 profile views

Landcruzer94's Achievements

Member (2/4)

-

I'm putting together a tote bag and noticed something about my stitch quality on the underside of my bag handles compared with the rest of the bag. Two layers of chrome, whether it be 2x 4oz testers, or the parts of my bag (2x 2oz) turn out beautiful top and bottom, no knots visible. My handles started as a laser cut top glued to a larger back, then trimmed after the sewing was done. Im disappointed with how the bottom turned out vs the top. Is there a reason why it would be so different when nothing else changed except the leather? I tried to add a few clicks of top tension but decided to finish the job before making any drastic changes. The only other variable I can think of is the speed of the machine changed as I tried to stay on my stitch line, but seems unlikely. Size 18 needle, Relicate serafil tex 90 thread Any ideas would be appreciated!

-

I enjoy my class 26. While I use mainly 92 and 69 thread, I have no doubt it'll do 138 nicely (EDIT - I forgot that the machine I bough came loaded with a bobbin and spool of 138, so that's actually what they set them up for out the door). I also have a class 4 set up for 138 and 207, and I appreciate the ability of the 26 to do thinner leathers. The class 4 (CB3200) I have really benefitted from a custom narrow feed dog I got from @RockyAussie, it was significantly easier to work with both thinner leathers and closer to the edge of my projects. If 138 is your go-to, you could maybe look into that option as well. As far as timing goes on the class 26 I recently posted a thread about the machine that I have, you've likely already seen it a few subject lines below. I do have to say though it's a lot easier to time than the CB3200 FWIW.

-

Uwe completely saved my ass with my CB3200 thanks to the same video! This community is awesome

-

The manual I used specifically was the juki engineers manual PDF from the thread I linked in an earlier post, it's for the 341N. Being that they use a different (bigger?) bobbin than the 26 there may be some differences and probably why my hook position was off when I followed the first set of their alignment instructions Here is an after video so you can see and hear the difference. Im sure there's maybe a liiiiittle bit more headroom to adjust, but I'm satisfied with the way it's sewing.

-

The slow grinding noise? Sounds like Owen from Planes, Trains and Automobiles? Believe it or not that's from the servo motor that they're putting on these machines. The motor unit itself is smaller and I'm assuming the same power as other motors, but compared to the servos on my CB3200 and Yamata 810 it's a clunky mess. The two aforementioned machines have a silky smooth run up, very low speed capable and are super quiet. This motor has a very touchy pedal that--while it can go slow--is either on or off. I get that it has the control unit for EPS, but if I had an extra servo motor I'd swap it out in a heartbeat. On top of that the motor pulley is slipping, causing a harmonic resonance and I have rubber dust all over the belt train. I've tried to tighten it briefly as I've been messing with the other bits, so now that I'm done I'll look at that deeper.

-

Okay, another 8 hours or so worth of fiddling and I can say that the machine is working great (in the forward position, see belopw) and I completed a flawless spiral while being able to lift the presser feet to make 90deg turns! Some things I noticed: I set my machine to the timing specs EXACTLY in both Al Bane's and @VanPlew 's video (two separate attempts to reset timing) I still get that Twang sound as the thread gets hung up between the hook and the inner hook race, you can actually hear it in his video too (Timestamped in the link). I feel that this is wrong after hearing what a machine sounds like with no interference. I ended up going to the Juki manual and set my needle bar to the specs they note, but for some reason when aligning the hook to the center of the needle at their spec of 2.4mm above BDC, the hook ends up at about 2 o'clock when the takeup lever is at TDC. I retarded the hook back to 1130(ish) after seeing how Uwe's machine was set up in his video and this was the fix. The factory setting of the hook assembly "saddle" was outside of Juki spec, so I also shifted that closer to the needle. The only issue I now have with the machine is that the reverse stitches don't exactly align with the forward, but I think I may need to mess with the feed dog height and research where others are hitting the reverse lever in the stitch process. If the hook timing doesn't alter that at all (which I doubt it does) then it's probably user error. Thanks everyone for the advice!!

-

Hi all, thank you for the responses! I stumbled upon a thread from last year that showed the exact situation creating the binding/noise below the bobbin case. Surely enough I was slightly out of time: I took a few hours this AM and adjusted the hook timing to spec, made sure the bobbin case opener was adjusted properly according to what I'm seeing on the videos within that thread. The noise is gone and stitches look great. The only thing I still have is the knot poking up when turning a corner. The check spring was the last question mark for me that I've been trying to understand the adjustments for. The only thing I've touched on it has been the bottom U-shaped limiter so far. @Wizcrafts I'll take a look at some of those adjustments you suggested. I'm confirming there is absolutely no tension on the upstroke where I would stop and make my turn. I watched inside as I turned to see if there was anything binding and I'm not seeing anything. At this point I'm suspecting either my needle is pulling the knot upward as it's coming out or there is some loss in tension on the bobbin, which wouldn't make any sense since it's a constant setting not impacted by anything other mechanisms, right?

-

Thank you all for the suggestions. I tried the suggestion by TomE, switched to veg and a diamond point needle and unfortunately did not remedy the issue. I did however uncover the source of the sound I referenced earlier. The slapping sound is because of the top thread binding within the shuttle(?) below as the string goes around. The below video shows the two slapping sounds, first as the thread goes over the first gap, second as it binds down below and finally the takeup spring slaps upward as it breaks free. This does not sound/look normal to me and may be the source of at least some of the tension issues that I have. You may be on to something, per the video I just posted.

-

Yes it's 1/4" or so above bottom dead center before I do

-

I have an issue with setting the tension on my Class 26. Here is what I'm working with Fresh size 20 LR needle 92 thread 2 pieces of 3-4oz leather Threaded and bobbin loaded according to LM Co's instructions. When I'm sewing I have the tension adjusted to bury the knot equally between both pieces of leather, but every time I stop and turn a corner (1/4" above BDC) the top thread pulls the bottom up and leaves the knot exposed. Doesn't matter if I use the foot pedal to raise the foot or just turn the piece under pressure the same thing happens. If I lower top tension to help the corners then all the knots start showing on the bottom. There doesn't seem to be a middle ground that will solve everything. I'm only adjusting the main tension knot, everything else is factory from Leather Machine Co. Sewing size 69 thread didn't seem to be an issue with a size 18 needle. I also note that the tension mechanism seems to be making some extra clang noises that I don't hear on others machines on YouTube. The final cycle is done by hand to show the kind of tension that's on the top. It doesn't feel right to me so maybe others can confirm.

-

441 Clone stitch length lever adjustment question!

Landcruzer94 replied to Landcruzer94's topic in Leather Sewing Machines

Well thank you to everyone that responded. I woke up early this morning and poured through a bunch of old threads and located the 441 engineering manual. Turns out the eccentric was still improperly adjusted. At 30* timing the needle should only move back 1mm when going from full forward to full reverse, the Uwe Grosse tuning video made it seem like it was 1mm from neutral to full reverse, so in all it was moving almost 3-4mm. Made some more adjustments and wow this thing is bang on throughout the gate and sewing better than it has in a decade. Super excited I feel like I can finally move on with my life! Lol Thanks again! -

441 Clone stitch length lever adjustment question!

Landcruzer94 replied to Landcruzer94's topic in Leather Sewing Machines

Thank you! Yeah I already have one half jacked up with about 1/8in total thickness of washers, and actually running out of thread on the screw! I figured there was something I'm still missing. I'll have to call Bob, I actually bought the machine from him back in 2014, I keep forgetting that! -

Hi all, I have a cowboy cb3200 that I have been adjusting on and off for about 4 years. Reason being, my stitch lengths in reverse are not consistently hitting the same holes in forward. I adjusted my machines hook timing to the specs graciously provided by Uwe Grosse, and then adjusted the feed dog cam eccentric touching the stitch lever so that (by Uwe's instruction) at 30* timing when pushing the reversing lever all the way down the needle assembly movesto the rear about 1mm. That all seems fine and good. My issue is that at full length of the stitch lever back and forth my needle hits the stitches perfectly, but when I use the threaded collar to lock the stitch length at a certain point it swings more in one direction than the other, messing up the reverse hole alignment again. In other words, the length in reverse is still going further than forward.... Now if I go by the gate itself, measuring it into equal subdivisions with masking tape and moving the lever to precisely those locations without the collar being used it works perfect. It seems that it's just the collar that's off? I'm sure there has to be something off that I'm just not getting. Any advice???

-

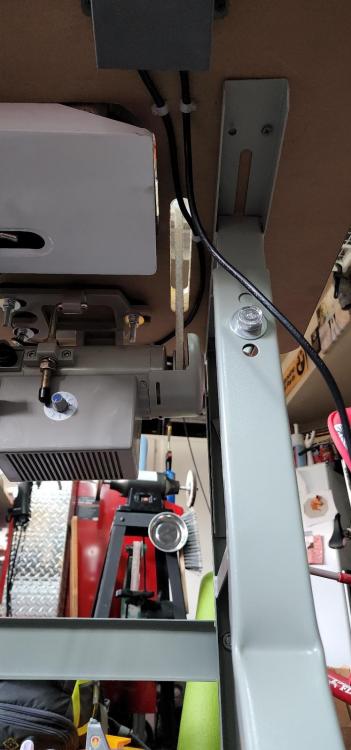

Acquired a Yamata 810 machine local to me, sold by a sewing machine repair man and seems pretty well sorted. I researched this machine for a little while and never came across a casting like this, and it even has an integrated bobbin winder. The peculiar thing I wanted to ask about was the stitch length wheel. It seems to only go up to "4", but has an unmarked zone where every other machine I've seen has additional range. Tuning it to this area seems to be okay, and it can still sew, but want to make sure I wouldn't cause any damage. Am I good using this range, as long as the reverse bar has more room to move? Second, for sewing leather I definitely need a speed reducer. I'm not seeing much space to work with under the table, how would one route the pulley? Lastly, any good part resources one would recommend? I have my eye on a rubber roller but wasn't sure if there were any other cool accessories that are worth looking at. Thanks!

-

CB3200 Inner/Outer feet timing

Landcruzer94 replied to Landcruzer94's topic in Leather Sewing Machines

Update: worked perfect. Thank you so much!!