MattW

Members-

Posts

88 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by MattW

-

-

-

-

-

No offense taken about the location thing. I'm in so Cal as Art said. Here are some pics of missing tool impressions.

-

Terrible week, First day at work of the New Year and we discover that some scum had broken into the shop and made off with over $9000 worth of tools and leather. Among the missing items are antique stamps and punches along with over $3000 in my personal stamping tools, many of which were custom made by Bob Beard. The stamping tools all had some white tape on them. There were also Barry King, Gomph, Chuck Smith, Baron and Tandy tools in the rack. There were over 70 stamps in all. Hopefully, insurance won’t give us a problem in replacing them but it will take months to replace the Bob Beard tools and I doubt I’ll ever be able to replace the antique ones. I have had to call back customers and tell them that I won’t be able to do the job they want because the stamps are gone. Keep on the lookout for a collection of 18 Bob Beard Stamps. Two of the ones stolen were designed by me and they will be easy to identify. The other tools stolen are CS Osborne, Weaver, and custom punches. These tools may have some red paint on them somewhere. I can’t begin to describe how depressed I’ve been this week.

-

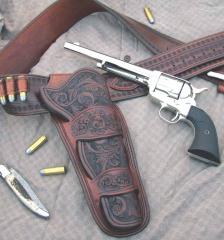

A Western Gun Rig For A Celt

MattW replied to MattW's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks for all the kindness. Where did you get that buckle and the conchos? Buckle is this one...http://www.highlandtradingcompany.com/shop/index.php?main_page=product_info&cPath=52&products_id=690&zenid=85a3ed46003808c64c788456ef3e86dd holster concho here...https://www.etsy.com/listing/168081480/concho-screw-back-rivet-celtic-openwork?ref=shop_home_active_5 belt concho here http://www.birdsall-leather.com.au/Y7936_dash_05w/Celtic-Rectangle-Concho-%28/pd.php Also what kind of stamp is that right on the holster? Barry King Double V Wave http://www.barrykingtools.com/page9.htm what would a rig like that run? Right about $1200 -

-

Muleskiner, I don't know where you got your information but John Bianchi has not passed away. He is now 78 years old. His father has passed away many years ago and bears the same name. The article at this link was also written by an uninformed person who didn't do due diligence before publishing a fabrication. http://www.sandiegouniontribune.com/news/2001/apr/27/john-bianchi-founder-of-temecula-business-dies-at/ Before you go around claiming that someone told a lie you better get your damn facts straight. John and I taught many years at the southwest leather trade show in Wickenburg, AZ. Uninformed people who pass on their ignorance piss me off.

-

John Bianchi uses his Ferdco for some work and his new Cobra Class 4 for other work. The motor on the Ferdco is an Efka. not positive on the model. The Cobra Class 4 has a NPS servo motor. AFAIK, all NPS systems have a synchronizer that attaches to the main shaft near the hand wheel. Heel down on the pedal raises the needle out of the work. If you take your foot off the gas the machine will stop with the needle down, just after the shuttle hook has caught the loop. This enables tight turns without any skipped stitches. The needle positioner motors are a godsend. It greatly speeds up difficult stitching. Both the Ferdco and the Cobra John uses have needle positioner motors. The new motors offered by Leather Machine Shop are much less expensive than the older NPS motors and give you the same results. (The ability to control the top speed. Stop the stitch in either needle up or down position. I hope this helps clear up any remaining questions about what John's machines are. If not let me know! The picture is of the motor on John's Ferdco. Matt Whitaker General Manager Frontier Gunleather

-

Helda, Nice to see you here......

-

Cowboy Couture Holster

MattW replied to MattW's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks guys. -

Anyone know where to track down the swivel hardware that is used on holsters to allow them to pivot?

-

I've got a deep scratch ( 3/16" wide, 3/4 long tapering to a point, and maybe 3/32" deep at the wide end) in the middle of where I want to cut my pattern. The end result will be black. I'd like to fill the scratch and blend it in to the rest of the surface which unfortunately will be smooth, not stamped or carved. I've tried using melted black wax before to fill scratches like this but the wax doesn't stay in the scratch. Any ideas? Thanks in advance for ANY ideas.

-

Holster Sewing Machines - Lets Talk

MattW replied to olliesrevenge's topic in Leather Sewing Machines

We (John Bianchi and I) just finished our Holster and Gunbelt workshop in Wickenburg last month. We asked Steve if he would let us use 2 of his machines during the class. We used a Class 3 and a Class 4. Both with the needle positioner. They both performed flawlessly. If you are at all serious about making professional looking goods a quality machine is the only way to go. If you start with a Boss, you will outgrow it soon and have a hard time getting your money back out of it. The finest stitchers in the world are now less expensive than they have ever been. The return on investment is incredibly good right now. If I were in the market for another machine now, the Cobra 4 with the needle positioner would be the way I'd go. The extra arm length is super handy when stitching on cartridge loops for western belts. -

fyi from Ketchum Thanks for writing Matt,,,,,, I ll do my best to help you ,,,, myfather , Cliff Ketchum opened the San Fernando Saddlery in the early50s with Art Hugenberger , off Woodman Ave, in Van Nuys , Calif. I justdrove by the area this year where the saddle shop once stood reflectingon my childhood days there climbing on the saddles ,,, the shop is longgone ,, They both did many things for the Movie studios in those days ,I m notsure with ones , and later my father bought out his partner . as i was told by an old timer ,when he was in his teens the saddle shopwas the place to hang out , if you wanted to meet some of Hollywood smovie actors , those where the good old days Cliff Ketchum apprenticed Saddlemaking at the Porter Saddle Company ,Phoenix Az. while in High Shool , under the watch full eye of LuisRinglero Master Saddlemaker ,,,, Sometime after WW 2 , pack his bags with his wife and young son andwent to Los Angeles worked for a few saddle shops til the San Fernandovalley saddlery was opened , and sometime during the 50s my fathertrained his horse that was in a few Disney's movies , Darby O'Gill andthe little people and Tonka , then began acting in a few movies ,,,,,,The Young Land , Pork Chop Hill ,,,, made guest appearances on GunSmoke and a few others A few other Great Saddlemakers worked at the San fernendo ValleySaddlery ,,,, Luis Ringlero . Mervin Ringerlo , Son of Luis . Iremember them , Art Hugenberger , Al Shelton to name a few ,, The waythey made a custom saddle to fit a horse and rider is a lost art thesedays , there are just a hand full of Master Saddlemakers left ,,,, Itsa dieing ART , a rider could ride all day without being saddle sore ,they where the most comfortable saddle made as one movie actor said Before the San Fernando Valley saddlery closed in 1967 someone said myfather was working on a saddle for the John Wayne ,, How many movieactors had saddles made from the the shop is unknown to me ,, whatfiles my father had where taken by someone after his death in Septemberof 1984 , many of his hand made tools too , sad , but his work lives on,,,, he engcouraged many other s to try there hand at saddle making ,like Don King , Verlane Desgrange , Pedro Pedrini , many other unknownsaddlemakers to me ,,,,, patrick ketchum