-

Posts

146 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Wicked Welts

-

Hand Sewing Thread Comparison - 10 Threads In A Row

Wicked Welts replied to Wicked Welts's topic in Sewing Leather

Thank You and yes, all were prewaxed, albeit very lightly on some. No opinion on the Brabours linen or any other natural or unwaxed jobs, I've never tried them (don't plan to either). I'd like to see a comparison on them though, yah never know..... My only experience with linen is with the stuff in this comparison and recently tried it for longer (14") runs on a project that is somewhat outside the norm - leather that's harder and thicker than my skull but same spi and techniques as the flat braided threads - now it would be wrong to base a comparison on that, or to tell you that it sucked so badly that I stopped mid-stitch and tossed that linen right in the trash, or that the synthetic braided thread kicked it's arse in every way imaginable, so I won't. -

Hand Sewing Thread Comparison - 10 Threads In A Row

Wicked Welts replied to Wicked Welts's topic in Sewing Leather

Not sure if I'll update with that one. It's not bad thread butt it's hard to get past the stink. I've got something better on the way, film at eleven or early next week maybe...... -

Hand Sewing Thread Comparison - 10 Threads In A Row

Wicked Welts replied to Wicked Welts's topic in Sewing Leather

Thanks to the thread donations from you and Doug I reach for braided rather than twisted threads almost every time now and only wish the $6 a roll cheapo threads came in larger sizes. Beyond that, I couldn't care any less about whatever differences there might be in construction or wax content or whether they put a tiger or an eagle or ahole on their packaging. -

First attempt at a case.

Wicked Welts replied to Wicked Welts's topic in Satchels, Luggage and Briefcases

Thanks Monica! I should have put a regular, non-dizzy pic and a bit of info in there. 8/9 oz all around except for the gusset (only) flanges which I skived down to somewhere near 4 or 5oz. Per request, the edges where only lightly sanded and burnished. -

Expecting to learn a few things I took the minimalist route and learn I did! As you can see, I've got a long way to go but I'm not sure if my thumbs are going to make it!

-

Hand Sewing Thread Comparison - 10 Threads In A Row

Wicked Welts replied to Wicked Welts's topic in Sewing Leather

Thank you and you're welcome! -

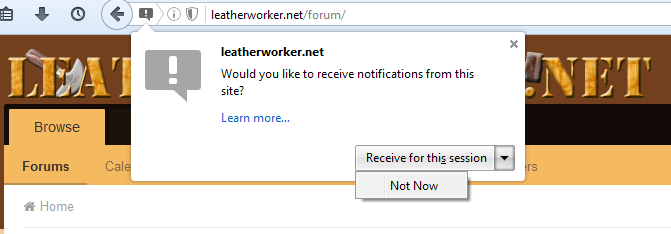

How do I block irritating web push pop-up???

Wicked Welts posted a topic in Feedback and Suggestions

I'm not sure if it's the new site or something with Firefox but I can't get this notification request thing to stop popping up when I select "Not Now". If I refuse the notifications (my preference), this box pops back up with every page change or refresh so it's constantly nagging while I'm on here (this site only) and following the link to Mozilla/Firefox help does nothing. Any help please? Oh and where's the 'preview post' option when writing a new post in the text editor?? -

I wear a 9.5 or 10 depending on the shoe but that's a generous offer that someone should jump on!

-

Love those chukkas there Seeg and I agree, that Double Dong thread is awesome too!

-

Has Anyone Used The Soledi Thread From Amazon?

Wicked Welts replied to Dougster's topic in Sewing Leather

Thanks for the samples Doug, love this stuff and the Dowco, they both did well in my comparison. So well in fact that I ordered several rolls of both and they arrived the other day and I won't be looking back now. I now have no need for the overhyped and overpriced stuff and hope they offer this stuff in larger sizes soon. -

All threads stitched in the same sitting by the same person using the same techniques and tools @ aprox 7.5 stitches per inch. All threads where used as delivered except for one (see notes in chart) and most threads where donated by forum members - thanks. All threads where measured to the best of my abilities using a cheap digital caliper, your measurements will vary. Thank You.

-

Oh, I just realized the pics are blurry, sorry about that. My 'good' camera met it's maker the other day after it lost a rather viscous battle with my drilling hammer. I think this computer might be next.....And yes, the cabinet was overflowing the minute it went up so this may be an interim step as my empire of scrap continues to grow.

-

Recently things got to the point where I had to address dye storage in my work space. The goal here was to keep the stuff I use a lot right near the bench and have the larger bottles and back up inventory in my derelict 'explosion proof' type cabinet in the garage. This started with a search of my junk room and I discovered this wood cabinet that I haven't touched in years. I don't recall where or why I got this thing but it looked like I last used it for storing audio cassettes so that might give you an idea of how long it's been kicking around here. I think these cabinets where originally sold for curio or beer can display, it looks like a pair of tall boys would fit nicely in each cubby but it's been a looong while since a sheetmetal can of suds was in my hands so that's little more than a guess. Right now I keep the 4 oz bottles in here along with a few of my home brewed elixirs and of course, the dye caddy hanging at the bottom. The dye caddy is based on various ideas I got from the smart people on here. I keep gloves, applicators and a few rags in there so it provides for a simple grab-n-go deal that also makes it harder for Murphy's law to take affect and also helps me avoid repeating Monica's attempt to refinish her floor with leather dye. The plastic caddy has compartments in the front half that are perfect for holding the 4 oz bottles so I carry that to the bench and ALWAYS return the bottle to one of those compartments instead of setting the bottle down on the bench. This makes it impossible to knock just the bottle over since it's always put back in the caddy. Now, when I say that, I actually meant that and EVERY time I open a bottle to put dye on a rag or whatever, I immediately return the bottle to the caddy instead of setting it down on the bench. Since then, I've had zero dye bombs going off in the shop.

-

Thanks for sharing that idea James, I doubt that would have crossed my mind otherwise. I do like the idea for those instances where you don't want or need to line something but want something different to finish the backside.

-

PM sent - thanks. Hopefully this will stop my head from spinning!

-

This Is What Happens When You Cheap Out On Awl Blades

Wicked Welts replied to jdm0515's topic in Leather Tools

I appreciate your sharing of that image, that's an excellent comparison right there! -

Thanks for the update, I'm getting close to pulling the trigger on multiple rolls for restock and this helps a lot. One last thing that's still causing a bit of head scratching for me is getting the size right when switching to a flat profile thread. I've seen references to size comparisons that go every which way on apples to apples so if you could elaborate on this it would be a great help. I'm currently choosing between .75mm, .8mm, .9mm (advertised at .030", .033" and .035") depending on my project so 1mm or 1.1mm thread would seem way too large for me if it were round thread. So, this brings the question on how this stuff looks as it is presented to the eye in a finished stitch line. The advertised size/diameter is not important, the way it lays out and looks when done is. In other words, if the Eagle 1.1mm lays flat and looks just like round .035" or better yet, if the Chinese .8 flat looks just like .033" round does, then it would be full steam ahead for me. Does that make sense?

-

Has Anyone Used The Soledi Thread From Amazon?

Wicked Welts replied to Dougster's topic in Sewing Leather

Thanks for the quick response, I'm looking forward to hearing how things compare for you. Regarding wax, I'm no expert either but I agree that less is better to start, it's easy enough to add some. My experience with Maine Thread's polycord (.030" and .035") is that it's waxed to the point that it's visible but still very dry feeling compared to the other waxed threads that I've tried form Tandy and the thread exchange. I call it 'cobby' for the for the lack of a better way to put it as sometimes it both felt and sounding more like I was dragging a tow cable over gravel than sewing. I experienced the exact opposite with the nylon mini spools I got from the thread exchange. That stuff had enough wax on it that I was able to make a few candles as I was stitching along, so I'm reserving that for my caveman stuff and that's it for them (their CS rep was less than helpful with a follow up sale so...). You answered another thing I was pondering as well, how the flat thread lays out. I was hoping that friction through the material would miraculously roll the thread so the flat side was always presented cleanly rather than rolling around at random. At least that's what I've seen in most pics of tiger stuff, it seems to lay flat all the time? Right now I do not cast the thread over the needle as I'm pleased with the way my stitching looks front/back but I'd certainly try that if it solves any issues with the thread rolling. Please let me know what you think of the wax on Main thread's stuff. I think I have 7 rolls split over two orders and it all has the same dry, straw-like feeling to it. Other than that, I think they got the quality and price right, so I'm hoping the Soledi fits the bill without having to spend what I think is silly money for el tigre. It's just thread after all right? I mean, it doesn't come with any cake or cheese does it? -

Has Anyone Used The Soledi Thread From Amazon?

Wicked Welts replied to Dougster's topic in Sewing Leather

Thanks for pointing this out, I'll be looking to restock soon so this is on the list. What do you think of the wax and the diameter? Looking through the reviews there, I see opinions at both ends of the spectrum; too much/too little wax, and size matching .9 tiger and others saying it's smaller than .8. Also, what do you make of the 'Exquisite Material' they say it's made from? It's polyester right? Thanks in advance. -

Art - I've never used the #104 rivets but just looked at Brettun's and those look like normal double cap rapid rivets. Am I right in thinking these are much lighter or thinner wall than standard tube rivets? The only double caps rivets I've used came from a crafty type box store and seemed very frail compared to the tube rivets from Tandy so I'm curious if the ones at Brettun's are different.

-

I use the splash setter hand tool from Brettuns Village also and it works great. I'm still experimenting with tap-tap-tap vs a single heavy bash but the biggest help for me was using a block of steel as a base and using a heavy hammer. I'm using a split head hammer just like the ones they sell at Brettun's, it's a No. 3 but so it's so old the baso face inserts are roughly two points harder than the back of Superman's head so it's about the same as hitting with a steel drilling hammer. They don't recommend striking their tools with a steel hammer but like Tinker Tailor mentioned elsewhere, I treat it just like any other struck tool that might shroom at the top and need to be cleaned up every once in a while. So far the only issue's I've had setting tube rivets with this tool are on me and I think you covered most of them already; Rivet placed in an oversize hole - I now make the hole undersize so the rivet has to be forced through the material. Most problems solved right there. Another possible chance for bending is placing the rivet too close to a corner or edge. Nothing scientifical here, but me thinks if it's too close to the edge, there's a good chance for 'give' in the material when stetting the rivet and that could start the tube bending. I've had issue with them being a hair too long and that's never good but I have yet to try cutting the rivets to a more precise length. I do not own a dremel and my only cut-off tool is way too big and aggressive for this so I'm not sure how I would go about trimming the rivet length without collapsing the tube or making it into such a project that it would defeat the convenience factor of using the rivets in the first place. Any suggestions on that would be appreciated.

-

The basic face image gives a sorta creepy 'floating' feel to it which seems perfect for the joker dude concept. Normally I like borders around stuff like that but I like how plain this one is. It's one more view on how things can be done without a border so you get the double thumbs up for sharing this time - -

-

I just looked at my notes - the other thread on the wallet is the from a bigger spool you can get for those POS speedy stitcher awl things. I gave the stitcher away with a small spool and kept the big one. It maybe worth a shot if you want to experiment with something cheap. Mine is their "coarse #150" and it's a waxed ploy too. Comparing it to the sample card from Maine Thread, this awl thread is just over .030". I used it with the same #2 needle as the .030 from Maine and it actually seems to sit nice but it was a royal beeyotch to get it through the needle eye sometimes even though it's about the same size. I think that's because the awl thread isn't twisted up as tight as the other stuff and my eyes aren't the best either. Thumbnail shows a closeup of the awl thread on the wallet. I'm sure for many this is a horror, but works fine for me......

-

Folks on here steered me to Maine Thread and their waxed polycord - https://www.mainethread.com/index.php/waxed-polycord On that page there's a link to order a free sample card. I got the card and a few colors to try and testing it out now. I've only tested it on a few scraps so far and I like it, seems like a bargain too. I need more seat time to figure out which thread size works best with which needle and my irons. I got the .030" and .035" for thicker stuff like sheathes etc but wish I got some the thinner stuff too. I would need more practice to give you anything more specific. Edit - Here's a pic of their Olive green in .030 @ 7.5 SPI using a John James #2 needle. I tried it inside my practice wallet just to try it out. The lighter colored thread is something else, don't remember the brand.

-

4 Slot Bifold Template & Directions

Wicked Welts replied to ducjes's topic in Patterns and Templates

Thanks for sharing this pattern, I really appreciate it. I just made my first wallet using it and I really like it. I used 2oz for the card slots and 3/4 oz for the rest.