nycnycdesign

Members-

Posts

49 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by nycnycdesign

-

Over many years we had most of our machines serviced at Jado in Long Island City. We also used to use Gregg at Keystone occasionally. We tried some other folks in the garment district (City Sewing etc) but were never too impressed with their work. Same with an outfit in New Hampshire. Does anyone have a good recommendation for supplier or repair folks in the Northeast? It's getting harder and hard to find good ones it seems.

-

I've only seen a dozen or so posts since May so I wasn't sure how active it was here anymore. I think it would be a great help to reduce the amount of sub categories on the marketplace. Why does there need to be an entirely separate page for used vs new? We're talking about so few posts that the division seems unnecessary. I think it would help make the marketplace streamlined and more active. This is what many collector forums have done to counteract hemorrhaging users to facebook marketplace, reddit, etc. Just a thought.

-

Not sure if the marketplace element to this forum is dead but reposting in case anyones interested. Pickup in the Albany, NY area. Zip 12834 Here's an imgur link with more photos. https://imgur.com/a/6iFmjwK Feel free to reach out with any questions. Need the space in my shop and we don't do strap work really. $2000 OBO

-

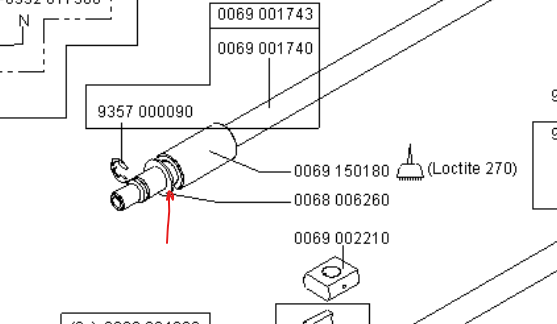

It does seem to be in the parts diagram. I'm not sure what it's purpose is though. My initial thought would be to reduce wear on the lock spring to the left but only the shaft moves so I don't see how that would wear over time really.

-

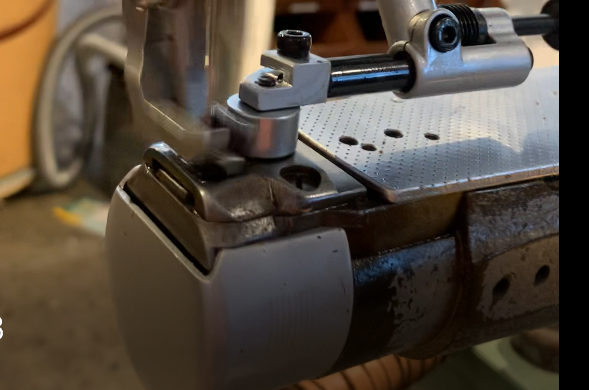

Thanks Uwe. Appreciate it. Found quite a bit of contrary info on the needle system online so when I saw that some folks used the 134-35 I just snagged a few from my 669. So the main issue was that the hook wasnt seating far enough on the shaft to allow for needle clearance. This is different than any other machine I run where I usually have a mm or two to play with the needle and hook daylight. Here you can see the contact the hook is making with the needle. There is literally no more space to move the hook any further and it's actually making more contact than the picture shows. Kind of a deceptive angle. I have another 69 here and the hook shaft is recessed back further in the casting than the one I'm trying to troubleshoot. This allowed hooks to seat and adjust properly. Unfortunately that machine has an incorrect needle bar and no tension setup (need one if anyone has one!). I removed the shaft from the machine and saw the washer that sits behind the spring clip. Im sure that this is important to reduce wear on the spring clip but I removed it anyway for testing. This now allowed the hook to move 1mm deeper to the right of the shaft and allowed all of the adjustment I needed to retime it. Now the machine is running and stitches well. I don't know if that washer is a critical part but if the Germans put it there it had a reason Im sure.

-

Hello all, I’m having an issue with a 69-373 I picked up. When I put in a 134-35 needle I’m getting contact on the hook and the needle is deflecting left. I’ve tried two OEM hooks and a brand new one from Bob at Toledo Sewing. Seems like the shoulder on each hook is too long and I can’t move the hook to the right on the shaft any farther so the needles are deflecting. The OEMs are better than the new one. Any ideas?

-

bump and price drop to $2,000

-

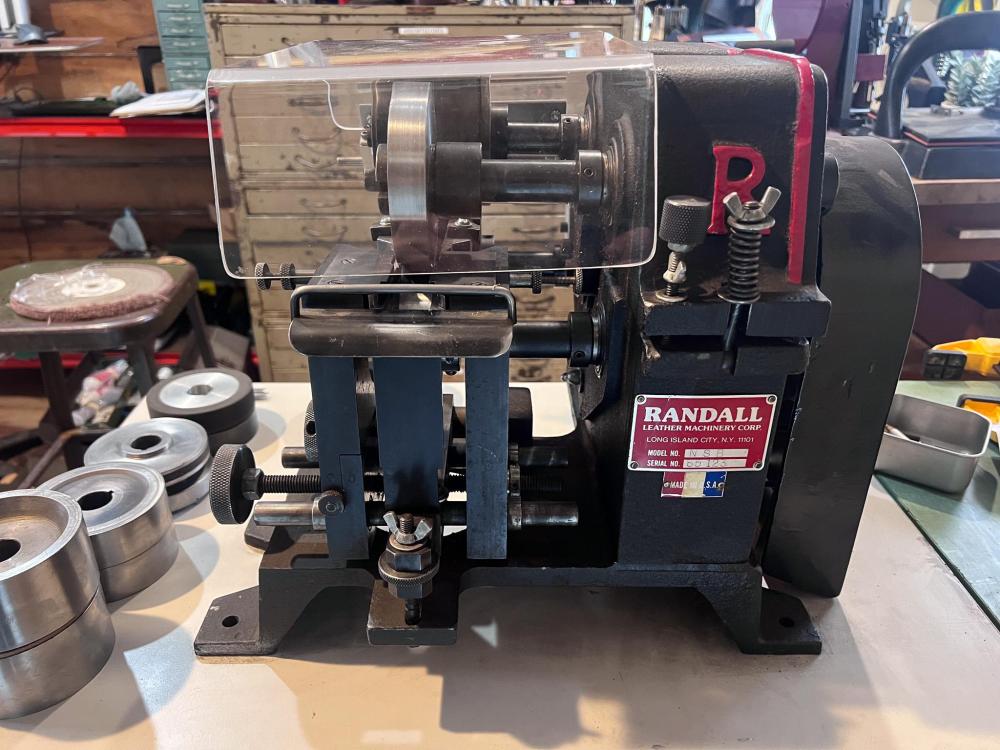

A nice Campbell Randall NSB machine with a few upgrades I bought from Dan. The acrylic safety cover has a switch that can be wired onto the motor so that it will only run when the cover is down. New table from CR with variable speed. Various sized spacers and a set of #1 blades on the machine. A few spare blades but unsure of their size. Pickup in the Albany, NY area. Zip 12834 Here's an imgur link with more photos. https://imgur.com/a/6iFmjwK Feel free to reach out with any questions. Need the space in my shop and we don't do strap work really. $2500 OBO

-

Personally, if it was me, I would look for a Kwikprint Model 55. It's portable, bomb proof, and most use a simple robotemp controller. You can't beat them. I have about 8 in our production shop and rebuild them often. Foil stamping is a delicate balance between pressure, dwell, and temperature and springs will probably get in the way of that. I have a dozen or so Kwikprints for sale in the New York area. Some 55's, 86's, and some goose neck stands. Reach out if youre in the area.

-

Retrofitting XY milling tables was pretty common on old school toggle presses like Kensols. I did exactly that on a Kwikprint 86 and used an old Palmgren XY Rotary table which gives me the left/right and a full 360 of adjustment. It's improved that machines capability significantly. I was only able to make this modification because the KP 86 has adjustable head height. Even the cheapo XY tables you posted probably wont fit under head most of the Chinese hot stamping machines. That includes the Dream Factory for sure. The other issue is the platforms relationship to the stamping head. They need to perfectly parallel across the board to stamp evenly. You will have no way of adjusting that on the XY in relationship to the chase/fixture/stamping head of the machine using the pictured set. The design of the Kwikprint gives you control over the platforms level using four leveling screws. It's a nice feature when you need it but it would still be better to have that cast into the frame itself as those screws work themselves loose over time (even with threadlock). In the photo below you can see the Palmgren rotary table bolted to the dovetailed platform of the KP. A ground 3/8" steel plate was then bolted to the vise as a work platform.

-

Not to split hairs, but Lucris is in Australia. Based on your first post I gather that Allpress dropped the ball and not Lucris themselves? It's important to be clear whos at fault if you're going to post something less than ideal about a company. You know what they say, bad press......is bad press.

-

I'm not sure who you bought it from but most of us in the states buy them from Henry Veenhoven and not Lucris directly. Good chap. Easy to deal with.

-

Nice! I always recommend the Lucris whenever I can. I bought on when I started and I still use it everyday even with cnc cutters and clicker presses.

-

We run a cnc cutter and two 25 ton atoms in the shop and I still use my little Lucris everyday. Great for wallet parts, coasters, dee ring components etc. It's also a good spot to stick a new employee until they get comfortable with the process. They're also a great option for smaller lexan dies that are highly accurate but delicate to say the least. Also, I don't agree with the notion that these little presses are a waste of money and I'd point out that bringing in a hydraulic clicker is prohibitive to most hobbyists for more reasons than I can count.

-

Personally, I always recommend the Lucris MA III over the Weaver. It's better built and comparable in price. The originals are built in Australia and available through Henry Veenhoven in Canada. Buckleguy and others carry a chinese clone.

-

Never seen a cylinder arm like this. Anyone know what they were designed for? Darning machine of some sorts?

-

I agree but there's definitely a "if you're buying it you already know how to use it" vibe going on with him. I'm happy with the machines I've bought from him though. He does his homework. I got a manual from Techsew for a similar clone. Can't attach it due to size reqs but PM me if you need it.

-

Hi all - I bought a 17" High Post machine from Sergey at Sew Pro. Obviously a Chinese machine with model number 85017. Techsew and a few others seem to have the clone as well. The only difference that I can tell between his and the Techsew is that the tension disc plate (?) on the Sewpro has a black lever that when pushed releases all of the tension on the discs. Unfortunately there was no manual provided, only a parts list. Does anyone have anything comparable?

-

Low Profile/Buckle Foot for Adler 69

nycnycdesign replied to nycnycdesign's topic in Leather Sewing Machines

Thanks mate. Very cool. Would you mind dm’ing me the STL? I’ll print one out tonight. -

Low Profile/Buckle Foot for Adler 69

nycnycdesign replied to nycnycdesign's topic in Leather Sewing Machines

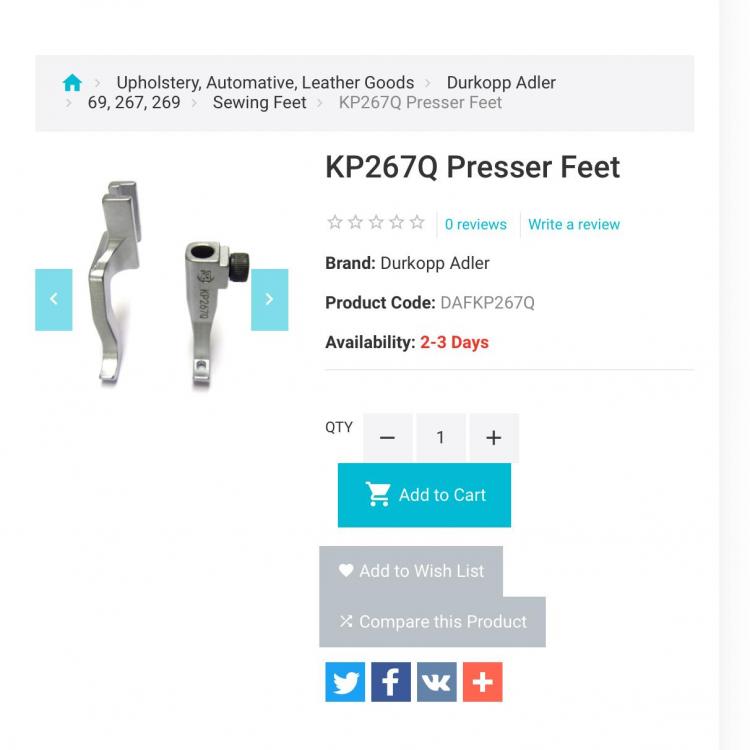

Thanks chaps. Im not in the shop right now but I had this video on my phone. LW wouldn't let me upload due to size limit. Uwe, sorry for the teminology mixup. I meant arm cover not throat plate. I had used your breakdown on another thread to convert another 69 into a binder. Worked great. I'd like to set this one up for narrow/tight stitching which is why I thought those feet would work well. So as I gather it, only the 267 needs a different gauge set and the 69 should work with these sans modification. VIDEO: https://vimeo.com/683961357 -

Low Profile/Buckle Foot for Adler 69

nycnycdesign replied to nycnycdesign's topic in Leather Sewing Machines

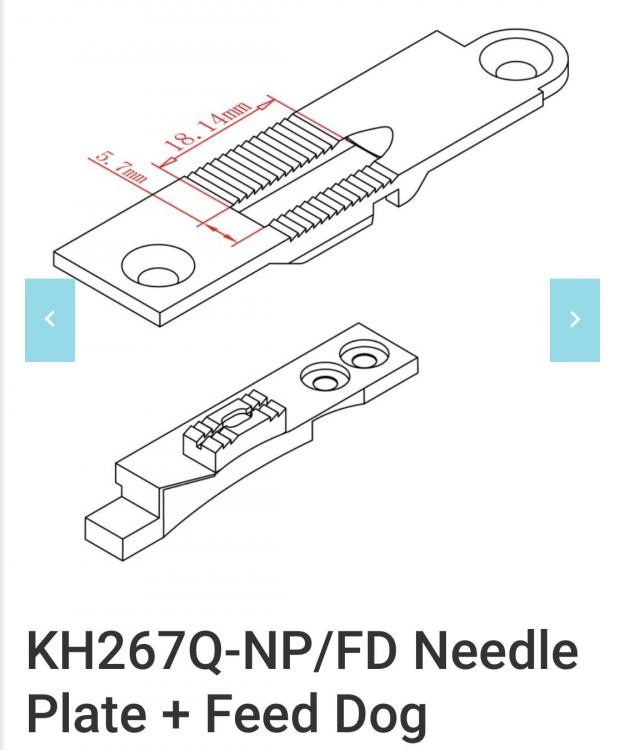

Really appreciate the responses chaps. I thought these were triple feed? It’s a 69-373 just without the moving throat plate but I believe it’s perfectly capable of having one without modification. I don’t know for sure though. Does that sound correct? KH lists the foot as needing this feed dog and plate but it’s unclear if that’s for the 267 only doesn’t even seem like it would fit the 69? -

Hi all Any ideas if this KH foot will work on an older Adler 69. Standard model not vibrating arm. I can’t get an answer from Kh. I’m looking for something very low profile like this for tight spaces.

-

I've got one of Dan's dual motor FAV AV2TE. It's a fantastic machine but if I did it again I'd forgo the second motor. Like a vacuum system, I don't think they're necessary at all outside of extensive production work. You'll get good enough at the machine within a few months that slowing down the feed becomes irrelevant.

-

Any of you chaps familiar with this machine? Similar to a Landis Model D I gather? I'll be picking it up tomorrow and will get a better idea of what it needs as far as parts go but looking forward to adding this to the shop. Thinking it will work nicely on a servo motor with a momentary foot pedal.

-

Anyone you'd recommend stateside for this? It's a damn fine piece and I'd hate have it fudged by my local fabrication guy.

.jpg.1144eb06e18a00d2117da5f449b07fb0.jpg)