DrmCa

-

Content Count

1,065 -

Joined

-

Last visited

Posts posted by DrmCa

-

-

People who do not know or understand the difference between mass-produced and custom-made make me sad.

-

Cocobolo is pricey.

Any hard wood would work.

I'd be weary of soft wood as it breaks and wears easily.

-

Good for you, OP!

Up here we get squeezed dry, in all respects.

From the country where one is allowed to wear a holster only at home.

-

Someone gave me a present of a few dozen 1 1/2" latigo straps thinking that I could use them for making belts.

They have these strange linear marks on them. They mostly run parallel but at different intervals, along the length of the strap. Here, at this end, they are tight but further left they get more sparse.

Are they wrinkles?

-

57 minutes ago, vpd66 said:I have no intention of buying one.

Whew!

They probably do not have a following because at that price tag they are unlikely to have a niche. I am glad they do not.

-

This is a copy of a domestic machine. You do not want one for leatherwork, especially not at that price. I could sell you the original for, let's say, $20 that justifies my time of salvaging it from the curbside.

-

Sellers have a tendency of selling their servo motor on eBay and then slapping their old clutch motor back on, prior to selling the machine. Just like they sell floor mats and roof racks, before selling a car.

The price sounds about right.

Plates can be found on Aliexpress quite cheap. I know a few sellers, CKPSMS, Germany Quality Store and Evernice come to mind, if you are agreeable to wait for a month or so. Otherwise GSM Sewing is the way to go.

-

17 hours ago, Garyak said:or on Facebook

It is just too bad that your group and some others (like, Anet 3D printer USB driver group) only have presence on FB because I consider its creator a criminal and refuse to aid and abet him by using his services. Hacking into his school's computer and seeding FB's database with stolen personal information of unsuspecting minors is still a crime, in my books, even though nobody else seems to care. Not to start a flame war, just saying.

-

Just one question: why did you not have them make the whole length of the rack?

-

Perfest! I am still in the Kansay Special and Pfaff 335 mode (facepalm). They are much taller. Also, K-legs can be collapsed as well if needed.

-

1 hour ago, fredk said:do you have to move your item along and sort-of guess where to put the next stitch?

No, you do not. You simply allow it to advance the material, and you turn it by nudging it in the right direction.

-

Check out this image, and you will see oiling holes (painted red):

-

10 hours ago, Garyak said:China leather patcher, enduro pro 220v ran 110v.

Do you mind me asking how you transfer power from the motor to the handwheel?

-

It's hard to see the machines through the sticker camouflage.

-

The worst thing to move was my Kansai Special coverstitch: heavy and mounted to the table. I basically immobilized the hole table inside a minivan, by tying it down with spare seatbelts.

Light-weight heads like Pfaff 545 can be taken off and safely transported between the 1st and 2nd row seats, on the floor, wrapped in corrugated cardboard or old blankets. Old sofa cushions help as well.

Since it is a dry head you can also lay the whole table on its side as long as the trunk permits.

-

1 hour ago, nylonRigging said:Always push down little bit on the Reverse Lever, to release pressure on that Dial spring/pin , so it turns smooth easy when changing stitch length's

A neat trick to remember! The problem is likely that mine is too easy to turn due to the lack of the prong on the pin.

I cannot see anything but a dark mark on my dial. Certainly no wear exists.

-

My impression is that those who buy them from China wholesale and re-sell them locally actually do a pretty good job of QC. They weed out apparently defective units and sell only those that work. If they would not, then they would have too many returns and negative feedback. I personally would never buy this unit from China directly, but since it was already present in my city, I knew that I could return it in the worst case scenario.

-

Yeah, it is the abomination we are talking about.

-

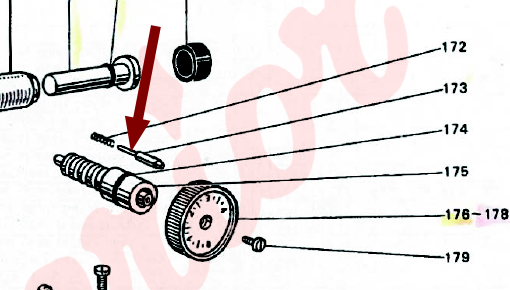

On my machine, the stitch regulator pin is broken. It does not have the thin section that lives inside the spring (pointed at by the arrow), and its tapered end that contacts the regulator knob is worn. I slightly sharpened it, on a lathe, and it holds slightly better ever since.

When I go into reverse, the stitch length knob sometimes turns all by itself. I lived with this issue for quite some time because I can simply keep an eye on the knob and turn it back, but since I was ordering parts from College Sewing anyway, I bought the replacement spring, with the idea in mind to turn my own pin. The problem is that now that I compare the old and new springs, the new one from CS is shorter and weaker.

I cannot understand how a shorter and weaker spring can keep the knob from turning any better.

-

Once I run out of their needles, I certainly will!

-

I got one, and it stitches, out of the box. Maybe I got lucky. Never tried it on the supplied "tripod" and instead mounted it on my own wooden base. There is a picture somewhere around here.

Since I got it and sewed it off, I never used it and am still contemplating either buying a copper and chromium plating kits and plating some parts myself or taking it apart and sending it to be chrome plated because all that is not painted is bare steel and doomed to rust.

I got this machine locally, from an eBay seller in my city, and it only cost me about US$150, at my door, so I do not see a point in buying from China directly.

Today it is even CD$20 or US$15 cheeper than what I had paid: https://www.ebay.ca/itm/193082243092

-

I too want that cookie!

-

Did you try hardware and fastener wholesalers? Not sure if HD supply has presence in Oz. They carry chains. Eh, I mean, they sell them.

-

You are my guardian angel, Fred!

What material makes the best burnisher?

in Leather Machinery

Posted · Report reply

Do not overthink it. Beech, birch, oak, all of the hardwoods will do just fine.