wrightsofman

Members-

Posts

7 -

Joined

-

Last visited

Recent Profile Visitors

1,658 profile views

wrightsofman's Achievements

New Member (1/4)

-

Various Hand Tools For Sale - Vergez Blanchard + Barry King

wrightsofman replied to wrightsofman's topic in Old/Sold

Both pricking iron sets, the half-moon knife, and the [very slightly] larger of the two creasers are still available! - Ross- 7 replies

-

- pricking irons

- vergez blanchard

-

(and 3 more)

Tagged with:

-

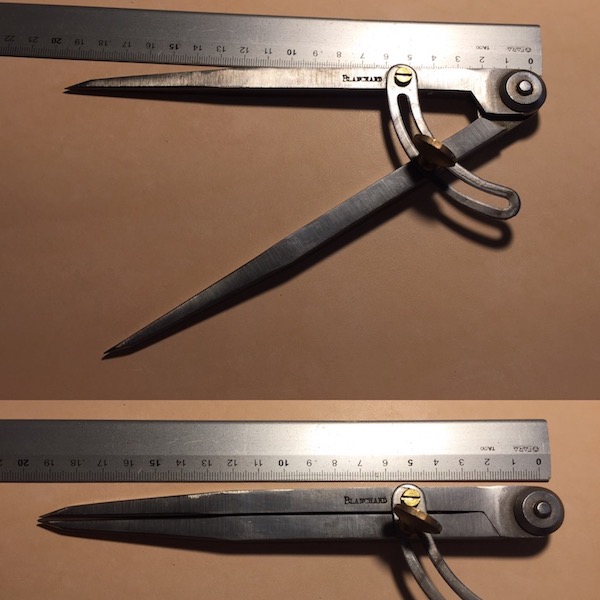

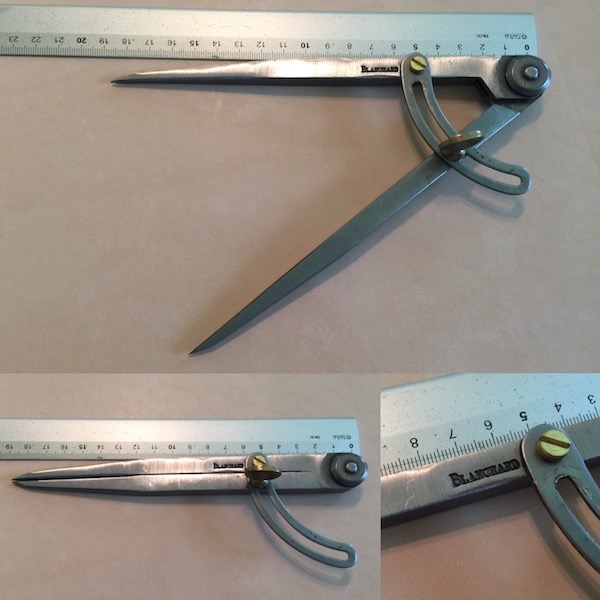

Continuing with the downsizing of my shop, I'm selling some of my lesser-used tools. I purchased all of my Vergez Blanchard tools from VB themselves. Vergez Blanchard Pricking Iron Sets: #9 (9 teeth per inch, 12 teeth and 2 teeth) - BARELY USED - $239 #6 (6 teeth per inch, 10 teeth and 2 teeth) - $219 (The 10-toothed iron has a bum tooth on the end that I haven't taken the time to sharpen out, because I rarely use it. Otherwise it's in excellent shape. Two Vergez Blanchard scratch compasses / Wing Dividers - I use these to mark my stitch lines. The two are slightly different sizes, but hardly noticeable. $59/each Vergez Blanchard "Couteau a Pied Demi-lune" No. 7 (200mm) - $109 I've sharpened this on my buffing wheel - it's big and as a sharp as a razor! Vergez Blanchard "Fer a Filet Maroquinier" (filleteuses, creasers and folders) - would like to keep them together, $149 for the entire set. Lastly I have a large, round, 64oz Barry King Mallet - minor dings, in excellent shape - $75 PRICES INCLUDE SHIPPING (to continental USA) AND PAYPAL FEES. Willing to ship elsewhere but will have to add additional cost! Here is a link to a Google Photos album if you'd like to look at the pictures full size: https://goo.gl/photos/vDfx17xTdqSzSHrH7 Thanks for having a look - let me know if you have any questions! - Ross

- 7 replies

-

- pricking irons

- vergez blanchard

-

(and 3 more)

Tagged with:

-

I'm preparing for a move to a city and my workshop is in need of downsizing - and the first piece to go is my beloved Fortuna Skiver! She was a pain in the beginning, until I realized it was operator error o_O, and then she worked like a charm. I've recently replaced the bell knife and have got two feeder barrels (one emory and one grooved metal for thicker leather. Comes with two sharpening rods for getting the burs off the inside of the knife after you sharpen it. I'm not sure how old it is, but it works really well and exactly as you'd expect from a well-made machine like this. I'm asking $1990. I'm located in East Texas and not unwilling to drive a few hours to deliver or meet someone for a handoff if that's convenient for you. If you have any questions, let me know! Here is a Google Photos gallery with more pictures: https://goo.gl/photos/VNukvumE6V5oCXpT7

-

Fortuna V50S Skiver grabbing and scalping leather...advice?

wrightsofman replied to wrightsofman's topic in Leather Machinery

Well, I spent almost an entire day practicing and trying to figure it all out - and now I see why you were having a hard time describing it! But as soon as I felt it, I knew exactly what you meant. It feels almost wrong, like it's not going to work properly, but it works like a charm! I've been skiving the past few days with no accidents yet (knock on wood!)! Thanks so much for your advice and responses - I really really appreciate it! - Ross -

Fortuna V50S Skiver grabbing and scalping leather...advice?

wrightsofman replied to wrightsofman's topic in Leather Machinery

Thank you so much for the quick response, Electrathon! What exactly is your set up? Like the placement of the presser foot, feed roll, and bell knife? I'm not sure how I could pull it through how I have it now - presser foot just at the edge of the bell knife and feed roll as close as possible to the edge of the bell knife. Your method makes complete sense, I just can't seem to visualize how you do it! Thanks again! -

I'm hoping one of y'all can give me some advice, because this machine is costing me a fortune in lost leather! I'm using it to skive 2-3oz down to 1.5 or so - and I go nice and slow, starting off with it barely gripping the leather at all, slowing lowering the presser foot bit by bit barely removing anything. Then it works really well for a spell, then as I move to a bigger piece or a piece I can't mess up on, it grips it and ruins it. I just can't understand it, and I'm hoping there's a trick I'm missing? I have replaced the bell knife, replaced the feed roll with an emory type (it came with a metal toothed roller), and the front tension spring did not provide much tension, so I added some electrical tape around it and that actually helped a lot to decrease the frequency...however, it still happens too frequently. Here's an album of the machine and some leather it's ruined! (https://goo.gl/photos/pPdV57qhxAp1Kha48) Any ideas? I'd be forever grateful for any advice or tips on more efficiently using one of these machines! Cheers! - Ross

-

I have 9 bottles of Tandy-Fenice leather edge paint for sale - ideally to a fellow leatherworker in Europe, as I am located in Brussels, Belgium. The 9 colors I have are: Navy Blue, Green, Yellow, Red, Neutral (clearcoat, basically), White, Black, Dark Brown, and Light Brown. I bought these just a couple of months ago in October and November from Rickert Werkzeuge where they sell for €29.95 each. In this photo album, you'll see the paints themselves, and I am also including the two projects I completed with these paints - a phone case with orange edges and a black stingray handbag. Other than a tablespoon of the yellow and red and about 20% of the black, the rest of the paints were not used any more than on a sample piece. I am selling them because I am moving back to the US (didn't know that when I bought them all!), and filling my suitcase with these 9 bottles of leather edge paint isn't really an option! I'm not expecting to get back what I paid for them (which is/was ~€300), so if you're interested, just make an offer and let me know your location to calculate the shipping costs! Thank you! - RF