BeltFanDan

Members-

Posts

40 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by BeltFanDan

-

Apparently, a bunch of belt people stalk me on FB, so when I liked your page, people checked it out. Your videos are also helping get tons of new followers.

-

Andrew said you been helping him out for 5 years now? How that come about? Also congrats on all the new Facebook likes. Seems the secret got out and you are blowing up!

-

Plates are zinc that are acid etched using photonegatives. Cast plates haven't been used in a long time. Too heavy and they crack easily.

-

I tried all the tutorials trying to use a sponge, lambs wool, brushes, etc. Could never get it right. A friend told me if it was something serious, then I should invest in an airbrush set up. I already had a pancake compressor so I just needed the gun setup. Got a good Paasche set up for under $200 including a variety of tip sizes, quick connects, and jars. It took a little trial and error but it was well worth it. If you are doing any colors other than black or dark brown, in bulk, airbrushing is a life changer.

-

I tried for years unsuccessfully. Now I airbrush everything. Only way I can get uniform color on such large projects. With oil based dyes, I cut it 50% with alcohol. With water based, cut it 50% with water. Several light sprays with the airbrush. It allows me to build the color up evenly, and slowly. Applying it straight up with a sponge or brush always came out too dark, and uneven.

-

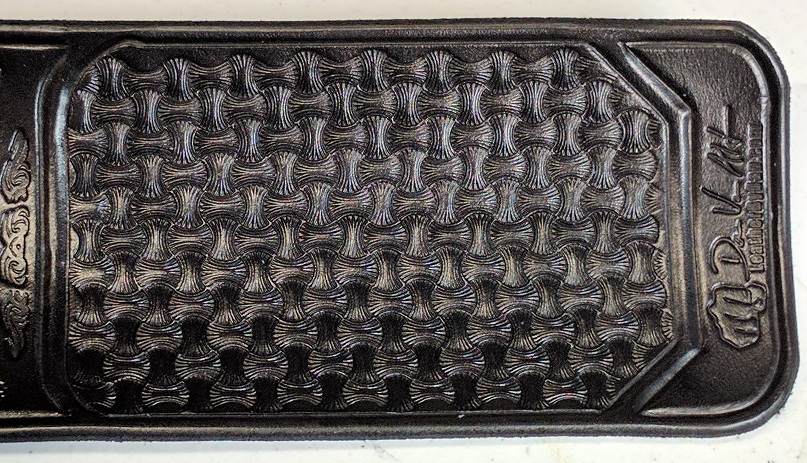

At one point I was buying a CNC machine to do my own plates. If that happened, it wouldn't be a problem making my own custom stamping plates. Unfortunately, I'm not doing that. I've been trying to find old leather stamps that are not made with some unique designs, but that's not reliable. Trying to find some out of the box thinking. My main areas are "fill" for the snap boxes like above, then the border that goes around all the plates like attached

-

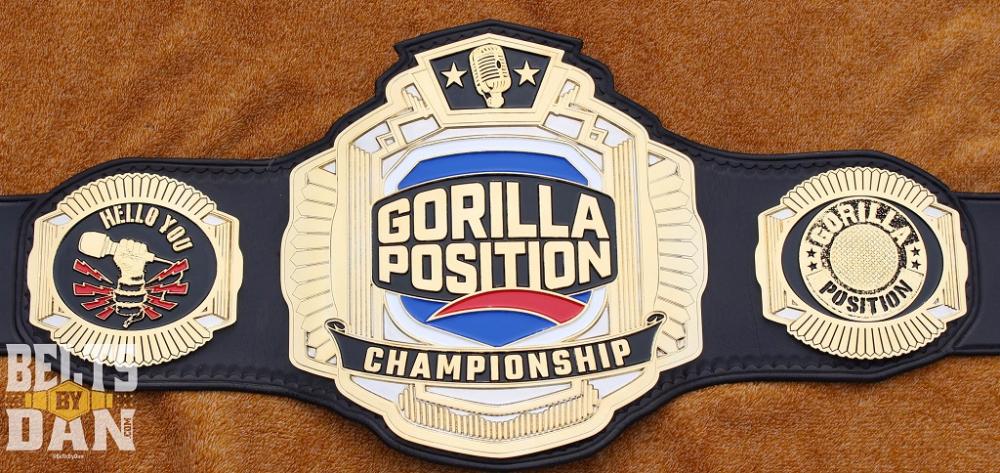

I make Championship Belts like the ones used on TV by big companies. The majority of my work has been replicating the straps that those who have come before me have done; replicating their style. I am trying to come up with new/unique ways to tool my belt straps, without turning them into long, laborious projects. Due to the amount of orders I get and the expected turn around time, I'm lucky to have a few hours to work on a single strap. While many of the intricate designs of traditional leatherwork would be great on a strap, the customers simply aren't going to pay for the labor. Attached are some different tooling styles I have been plating around with. I guess I'm at a road block and looking on some advice on some different stamps, techniques or designs to incorporate into my work. Thank you Insert existing attachment Due to the size limit here, my full gallery is available on my website, BeltsByDan.com

-

Looks great. Gonna pick one up this weekend. See how there is breaks in the post so it folds over? I have to do that manually with needle nose pliers with Tandy snaps, then I can use the normal anvil and hand tool to finish it off. Such a pain and waste of time.

-

I would advise to get posts too long, and grind as necessary. Another problem I had with a snap vendor is, that the male button pieces, the centers on the old stock, was at the bottom of the snap, and sat flush with the leather, so my posts were exactly correct, and curled over properly. New stock, the bottom of the male snap center is about half way in the middle of the snap, so now, a slightly longer post is needed (I use 8/9oz leather). Instead of buying all new snaps, I am just tooling the backside of the snap hole, so the post has a little extra room to clear the other half. Snaps give me more problems than anything else, but I really don't want to buy a snap press and die kit. Is that hand setting tool from Hobby Lobby better than using the anvil and setter tool?

-

DOT Fasteners is one company, but you have to sign up for an account and I believe there is a $50 minimum order.

-

I've had this problem for a while too. I've narrowed it down to the snaps itself. A few years ago Tandy Leather changed the manufacturer for their snaps, and they are not as strong. The posts are not strong enough to withstand the pressure of the anvil and punch, so the post collapses in on itself, and you don't have enough of a curl over on the top. I now buy my snaps through a few different manufacturers and have had excellent results.

-

What Color And Brand Dye Matches This?

BeltFanDan replied to BeltFanDan's topic in How Do I Do That?

-

My last Ohio Travel Bag order didn't go so well. it looks like they changed something with their snaps too. Their old snaps, the male end, the hole for the post was all the way at the base of the snap. The new ones, have this around the middle. Thus less of the back post folds over. Depending on the thickness of your leather, the snap might not be as secure and pull off easily. Why is everyone's snaps so difficult?

-

What Color And Brand Dye Matches This?

BeltFanDan replied to BeltFanDan's topic in How Do I Do That?

Thanks for the advice, I'll probably build the color up, do it like 40/60, 50/50, 60/40 and a little higher, then finish it with satin sheen. I'll let you guys know how it goes. -

What Color And Brand Dye Matches This?

BeltFanDan replied to BeltFanDan's topic in How Do I Do That?

I am doing a 5ft by 1ft wide piece of leather. Is that still a suitable solution? Thanks -

I am working on a project and looking to come as close to this color as possible. I would call it lavendar. It looks like an acrylic topical, not a dye. Is anyone familiar with anyone who makes a color as close to this as possible? Thanks; Dan

-

My First Hand Sewing Job, Now I Want a Machine

BeltFanDan replied to BeltFanDan's topic in Sewing Leather

Thanks for the suggestion. Any specific brands/models? The only thing I've seen so far is the Tippman Boss. -

This is the first hand stitched strap I did. It took way too long to do. I will be doing more of these likely in the future, and would like suggestions on a good machine to do this. I will be using 7-10 oz tooling sides, and want it to look the same as what I have done. Your suggestions are appreciated. Here is the hand stitched one: