-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by radrider

-

Looks to me like it normally would have a large lever on it that would be used to do something, maybe raise the feet or raise the foot clearance while sewing? Mine doesnt have the lever unfortunately so it will be difficult to tell.

-

I think you need to get out the Dremel and do some sculpting ;P Also depending on what machine you use, there are feet available that have little guides built into them.

- 22 replies

-

have you tried right / left zipper feet?

- 22 replies

-

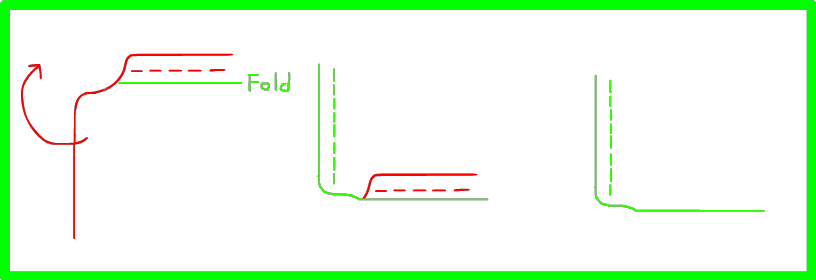

something like this to remove the bulk of the corner fold. Maybe without the rounded edges though as it doesnt fit the raw angle corners of your design

-

This is what I would do. Simple large pocket on the front to meet the lines of the bag. making it this large allows a wide opening that still conforms well with the closed lid. Keep the bottom seem hidden with a fold to make the bottom of the pocket have some room so things dont get wedged to the bottom.

-

Impressive. You guys just went up a notch or 2 in my book. and Christian...maybe lay off the whiskey bud.

-

Sounds like you need a better tech to stop by. I think an experienced tech would know what the issue is on a simple machine like that. "stitch throwing off the time" is a real non-answer to whatever the problem is.

-

Converting Efka 3 phase to single without convertor

radrider replied to radrider's topic in Leather Sewing Machines

my motor starts with serial number 12! looks like im in luck so far! tons of "real" sewing work to do today but ill get back ASAP with my progress in converting. -

Converting Efka 3 phase to single without convertor

radrider replied to radrider's topic in Leather Sewing Machines

@Uwe yet again with an amazingly helpful reply, thankyou! Also I found out what the "bulge" in the middle of the sewing arm is, it has the ability for a lever to attach that allows manual lifting of the feet, seemingly a very rare addition to a 291 machine(I still have not found any photos of a 291 with this addition, however I saw some 219's with the same attachment) I owe you big time @Uwe! -

Durkopp 291 walking foot machines for sale (22)

radrider replied to CaptnCaptain's topic in Old/Sold

@CaptnCaptain check my latest thread about converting without a converter :D- 18 replies

-

- walking foot

- industrial

-

(and 3 more)

Tagged with:

-

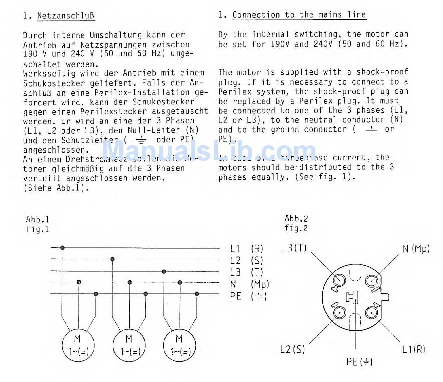

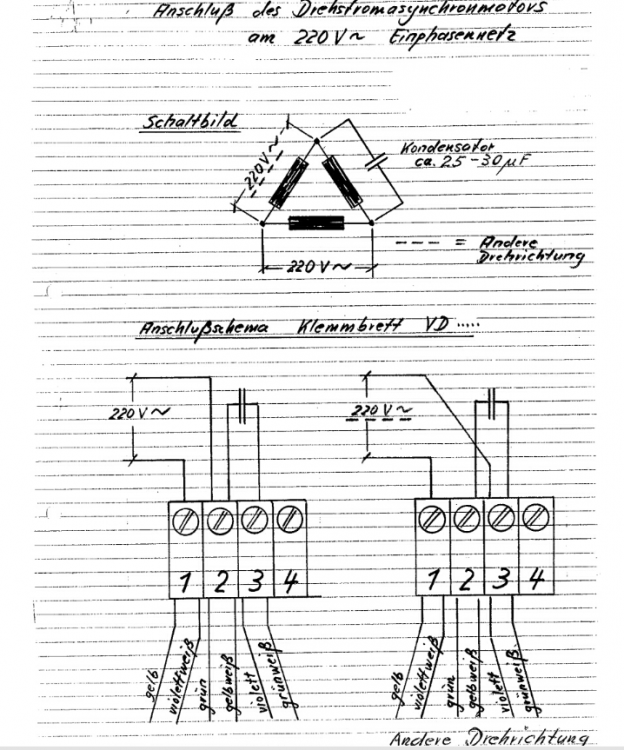

Hi all. Last week I posted about a couple 291's I picked up with complete old efka variostop motor/control. They have 3 phase and i was curious in how to convert them to single. The all knowing @Uwe found a page in the 291 instruction manual that seems to hint at the possibility of an internal switching of somethings to convert it to single phase. I contacted Efka and they said it is indeed possible and sent a diagram of their own, but in German ...Schiesse! - "Attached you find the manual how to change the voltage from 3ph to single phase. But attention our company didnt take any warranty if you do that!!!!!! The motor can burn up!!!!!!!!" Thats OK, I've got an extra motor should this one burn up, and I am planning to purchase new efka servo system in the future. So my question this time. As I have electrical knowledge somewhere between kindergarten and grade 1, I could use a little pointing in the right direction. (OK thats an understatment) Ill work on translating the German text to English in the mean time.

-

Durkopp 291 walking foot machines for sale (22)

radrider replied to CaptnCaptain's topic in Old/Sold

Do not buy sight unseen! many are missing important parts you will need to go over the machines there yourself. I was the first there and grabbed 2 of the nicer ones but there was still plenty of "good" ones.- 18 replies

-

- walking foot

- industrial

-

(and 3 more)

Tagged with:

-

trustworthy or not, i spoke with him a fair amount and it seemed like he didn't really know much about sewing machines(misspelled Pfaff and Durkopp in the ad, didnt know what any of the models where). The machines are not testable unless you fix the power cable which seems was "hard" connected before and has been cut. It is a HUGE factory and I walked through most of it to get to the machines. There where very few machines there and what I saw looked nearly brand new. He said they source nearly all of their fabric sewing in china and now do final assembly there. The factory is called Dynasty Furniture. For $180 it was well worth the risk I think, these original Durkopp feet alone are nearly worth that. Time will tell. I for one love a bit of a challenge.

-

Thanks UWE! that is a great find! I will surely try this out.(may need to take a refresher of electricians for dummies though ;P)

-

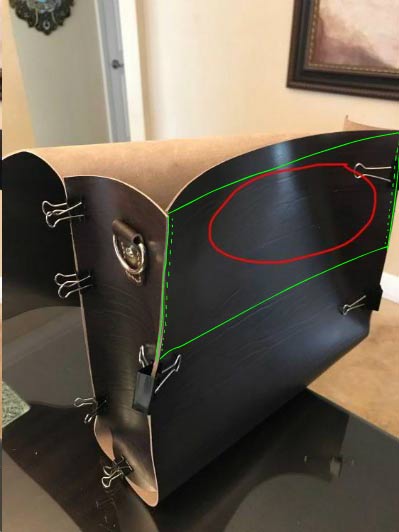

Swap to a 110v and lose all the auto features? My sewing shop seamed to think that was the better route to go, but I do very much prefer an automatic machine at this time, especially if it all works. (ive got an adler 167 and pfaff 545 and 1245 manual setups, but id like this to be an efficient workhorse) I may just be too noob but I couldn't locate a manual foot lift on the machine. The knee lift is air as well. Difficult to find much info on the 291, especially this variant with the big bulge on the bottom/middle of the machine arm, I havn't seen any photos of a machine with the same "bulge".

-

Make sure to go over them and check that bobbin cases arent missing, they have the correct walking feet, etc . also some had considerably more play in the needle bar than others, some where missing the efka display The seller is very friendly and seems honest, hes selling them for his boss to make room in the factory.

-

I did not buy the remaining machines, the number you can call if your interested in buying them is 647-459-0110, 5 hours ago there where still 30 remaining, mississuaga just beside the airport.

-

couple more pics. Does anyone know what the bulging chunk of metal in the middle of the motor is? I havnt been able to find any photos of a true twin machine online.

-

Hi all. Ive been lurking on this site for several months. It is a goldmine in knowledge no doubt...so here goes post #1 Just today i happened upon an ad from a furniture manufacture pretty much tossing out their machinery. 30 adler 291's with efka motors/control. Although they are 3 phase and i havnt got much clue how difficult it will be to convert i thought i would pic 2 up and see what you guys would reccomend. At 180 canadian each it felt like a pretty good deal. They are seemingly in good condition however i only have the word of the seller that they where all running 2 years ago and have been collecting dust since. So. My question is. Does this look like something i should invest time and money to get working? If so what would you recommend for conversion, what are the draw backs. Could anyone chime in on this setup and what they think about it?