Sledzep01

Members-

Posts

106 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Sledzep01

-

Had it out twice already now. You? were right, it was not being touched when I lifted the foot. But I still broke thread after I adjusted it to be touched. Now about to watch again because I am not picking up the bobbin thread...I now have the little bar touching at rest and want to try again. I really believe my thread was diving down between the tension discs before this... Certainly not time to step away yet. I am very mechanical, BUT the only sewing knowledge I gained in the last 2 weeks. Wish my Mom was still with me. She worked for singer back in the day and made all her clothes, all our suits etc. Forget Halloween or the school play I had it all. Now I dont even know how to wind a Bobbin!! Sewing first, I need stitches!! Thanks for everyone helping! I would probably be done by now if I had some OMN's (Old Man Needles) Sled

-

I know his, and that video well. I understand what you mean I will check it but already bought the unit too, mine looked like it needed to be polished anyway and I want it to get set right in the beginning so later all is smooth Thank you Sled

-

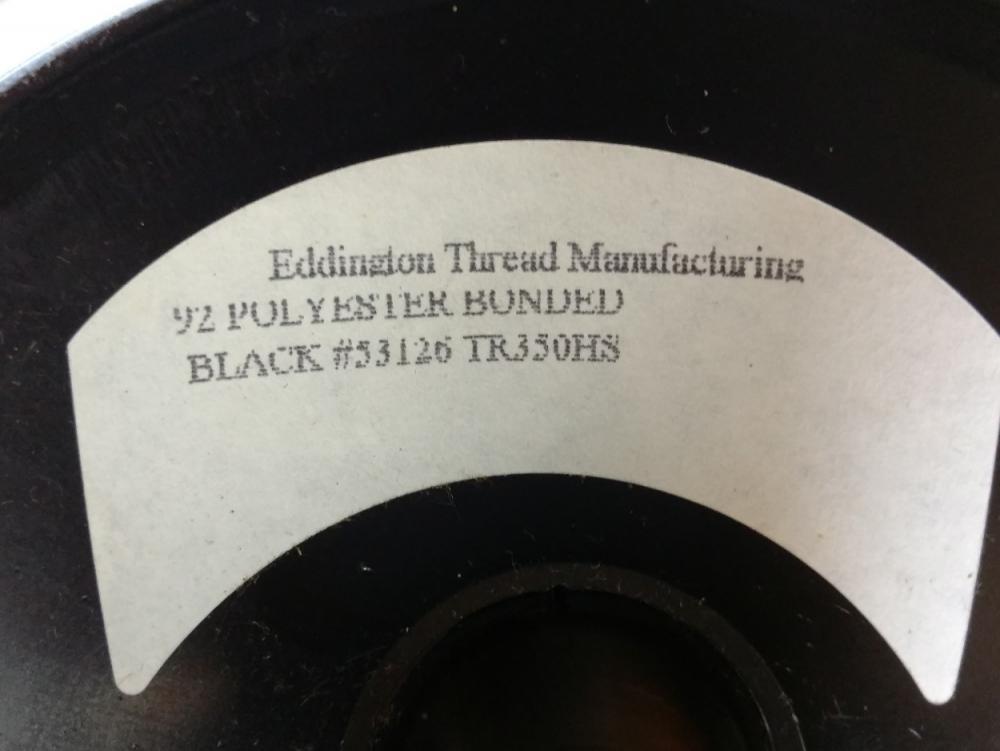

I have 12 1lb spools (1 full see the rest ) of Eddington #90 black bonded nylon thread. I kept plenty for myself so I would love to trade for a colored bonded nylon thread in #90 or something else I do not have. I do hand stitching too and do not have everything I need. Mallet? Carving knife? Stamps? Snap tools etc. Make an offer!

-

Bought, thank you. is there a trick to installing? or just screw it in? Thnx Sled

-

No matter how tight I made them they wiggled. I am sure they are together right, it's as if a washer was missing or something. the thread was literally running on the shaft. I added a washer at the machine side and was able to tighten to make them meet and have adjustment capability... Without it they wiggle when tightened to the end of the threads on the bolt. I will look at the parts manual to see if something official is missing. Is it possible the discs have flattened over the years?? I am sure I am following the manual for the thread path. The only changes I made was to use fewer (Just 2 in different ways) of the 3 where you make the S shape. I used less because it broke and I thought I had Too Much upper tension. The stitches did not change, they just went further before the TOP thread broke Sled

-

Your a Pro Bob, don't you mean "Reform it" BadumpBump! Tsch! I will check all of this, thanx guys

-

Really? I trust you and will do it, it just seems so tight through there already. Maybe the thread is stronger than I think. Also, if you look at the bottom/brown side you can see that the feed dogs are leaving marks on the leather, Does that mean that there is too much pressure and I should back it off??

-

Just threaded up my machine for the first time. 92 bonded nylon. #20?? needles? I keep breaking thread even if the tensioner is rattling loose. there are 3 holes on the machine I have used all 3 every way I could and switched to only two... Discovered that it is never tight before the tightener. The thread was seeming to pull easily, it certainly pulls easily from the bobbin. I have followed all directions, and tried 3 diff bobbins The machine thread keeps breaking leaving me with the mess below. The darker leather is the bottom bobbin side what needs adjusting?? Heeeeeellllllpppppp

-

I just moved one myself in my Venza. thanks to this post I tilted, Drained, Funneled, Removed the head AND the motor (and light) and then it slid in on its back into the hatch. From what I have seen and read when installing the motor should sliiiiide onto the bolts with some washers and nuts just there to hold it until you get the third one in and tighten it up. Not in my case, there were some super rubber and metal bushings on there. I had to hold the motor up with 1 hand while I put a bolt through the hole and then a nut on the bottom. Whew it's done! Its running but I do not believe it is oiling well. thanks Sled

-

So I did slow down # 2 and if, IF, it is fair to judge the pulley size on the motor to the shield protecting it I think I already have a small pulley there. I put it back together filled it with oil and it is running!!! Still very touchy, I need to adjust it so that it is harder to press. But I am very happy I have it. I will need to train my foot. I am also hoping to get a larger pulley (Hand pulley??) How much oil should be in the window?? when I have it running at medium speed aI get a drikp a second. Is that right?? Or should it be filling that window?

- 7 replies

-

- 241-12

- industrial

-

(and 1 more)

Tagged with:

-

So I have enough cleanout oil I can run this tonight. any ideas on how long to run this oil through it to clean it out while I wait for my internet oil to arrive?? I plan on doing both these upgrades in the next weeks Slow Down #1 Slow down 2 Heavy Duty Sled

- 7 replies

-

- 241-12

- industrial

-

(and 1 more)

Tagged with:

-

The hole in the middle of the front piece here. If it will not shoot oil out I may not need it... BUT If you are parting out maybe I can add to that so that the shipping is worth it for me and the trip to the post office for you. Can we take this offline for that part? will send you a PM

- 7 replies

-

- 241-12

- industrial

-

(and 1 more)

Tagged with:

-

thank you. I ordered oil. 1940, WOW!

- 7 replies

-

- 241-12

- industrial

-

(and 1 more)

Tagged with:

-

Also there is a missing cap (Not this one on top, but looks like it) missing on the front. Can someone tell me the name so I can try to order it? there are plenty of parts lists out there but none with pics pointing to the parts for us dummies Sled

- 7 replies

-

- 241-12

- industrial

-

(and 1 more)

Tagged with:

-

I Just bought one.I have transported it home and will be adding new oil to clean it out before I add the oil that will stay when I operate it. How long should I run that first oil to clean it out? The oil I removed was not clear. I was told it was Synthetic Honda Motorcycle oil... There is/was a little bit of brown staining in the oil tank. The oil did not look bad but I am going the traditional route. Also, Is there anything special about these machines I should know? Any parts that regularly fail? Common problems? anything like that? I am extending the clutch actuation? arm to make it less sensitive. (Possibly a servo motor later this spring but not right away I may want a smaller pulley on the motor. I definitely want a larger hand wheel with larger pulley. Not just for speed but for my large hands. I have searched but nothing specific came back and said yeah this is bigger and fits. Also the serial # is AF677193 can anyone tell when it was made? what year? Thanks Sled

- 7 replies

-

- 241-12

- industrial

-

(and 1 more)

Tagged with:

-

I did a search on "oil" and received nothing. I am going to pick up a 241- something tomorrow. If the oil looks dirty what do I buy, and where is the best place to get it?? Should I replace the filter when I change the oil too, like my car? Thnx Sled

-

I did read that, and everything related to the 241 on this board. And you and everyone here have been very helpful. But I cannot do what's "right" for leather at this time. I am not a full time leather person or anything else except Network Engineer. I don't know what I will do with this machine but I think it will be mine Saturday. $200.00 plus gas with the extra parts, looks clean... After a quick servo motor I probably won't even sew my finger to something. So far in the 6 weeks since I have owned stitching needles I have not even touched any Veg Tan leather. Just leftovers and couches and coats. I don't mind that the machine is not rated for making bags, but it does seem like a decent deal for the combination stuff I want to do on it. It still seems like it will hold up better than some of the others I considered like the 401A. Yes I will need to rev it up at (at least) the beginning of each session to get the oil going, but considering how often most home or other non automatic machines probably get oiled I hope to be fine. I watched about a dozen videos about it today and I am hooked on the all metal puzzle of cleaning and adjusting it. I have worked on much more complex machines in the past (Not sewing machines though) The only downside in my mind is that if I get to using it well I will stagnate on my hand stitching!! Keep the opinions and tips coming if anyone wants to, but my mind is made up at this point. I really did/do appreciate all of the help. Hopefully this will be soon, just not as skilled Sled

-

To be honest I am not aware of anything... And thank you all for helping so far. I am sure there is a way to slow it down right? the 241-12 that said consew said 1725 rpm on the back. I figured it would be close to that, and somewhere I read that was not too bad... better than a motor that was near 3k (paraphrasing what I read somewhere) I do know about the bath. If I can handle it will it sew jeans, light canvas and light upcycle leather from couches and coats? It looks great (although I do wish it was the black and gold...) this is what the ad says. Certainly looks strong, and worth $200.00 Am I wrong??? is this NOT variable speed?? Wow that would be bad!! Wizcrafts, you seem to be very knowledgeable, can you tell from the pics which model it is and if it is variable?? Runs good, only selling because I have cancer having to quit sewing.Will sew heavy material, leather, canvas layers of denim Includes: 100 bobbins100 needleslight with extra bulbextra long cordowners manual on CDseveral spools of Mylar thread. Sled

-

OK Update If I can get a truck I will buy the grey 241 for $200. This Saturday They said it comes apart... I might need to do that if I cannot get a truck. I have a Toyota venza hatch back... PRayers needed if I dont get a truck Can anyone tell me what I will need to do that. I have tools and I am mechanically inclined I am going to bring an empty gallon container and funnel for the oil... I was told its expensive and the tank comes off too. Will I need to drain it? or just put it on plastic??

-

I see 2 singer 241 near me on tables, one is black and says 241-12 Listed as that but says consew on plaque in pics The other is grey and justmsaysn241 Any info on these?? the 241=12 is $200 and close, the grey 241 is $250 and is further away, looks newer and comes with hundreds of needles and bobbins. and some thread Can the grey one be easily removed from the table for transport?? I read the 241-12 article here and fear the oil on needle thing. will the grey one be the same?? Sled

-

Sorry to be a pest I only need forward and reverse, do the other 2 i linked to accept stronger tread and needles?

-

I see a Black 301, the 401a, and a 500a. All look metal on the outside... What about Pfaff?? 301 500a

-

so they would just be singer 127... not 127### or something? How old are these models, will they be one of those cool looking old black ones? How about the white rotary? I am on shopgoodwill.com and see some of these. There a million machines there in general White rotary singer

-

I read the other thread about the 301 and 401. Nobody liked it for leather. Is that because of he type of leather you use. So, I don't even know how to sew yet, I want to be able to sew some jeans, light canvas, and leather from couches and coats together occasionally It is a hobby, I do not have a business, Hell I only just made my first stitching pony a week ago... So will kit really not sew leather from an old couch onto some jeans. If it can do what these videos show I would be happy. It will probably cost me under $75 video 1 video 2

.thumb.jpg.a36f517b745a416d2c2419053fde7c53.jpg)