Sledzep01

Members-

Posts

106 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Sledzep01

-

Is tooling the same as cutting in your opinion? Because I have no plans for actual tooling/carving. My brain says I wish, My hand says HAHAHAHAHA! Sled

-

Knife Sheath for Esee 6

Sledzep01 replied to Firewalker's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I cant wait to get that good! sled- 23 replies

-

- tiger thread

- air brush

-

(and 6 more)

Tagged with:

-

Is tooling the same as cutting in your opinion? Because I have no plans for actual tooling/carving. My brain says I wish, My hand says HAHAHAHAHA! Sled

-

I see statements like this all the time. Many work as intended... someone comes along thinking they would like to do this and gets discouraged by the statement. thereby creating 1 less competitor on Etsy or whatever... I remember taking a class on marketing a Loooooong time ago and the key thing I remember was that the teacher would take the sunday ads and spread them on the floor, go make coffee, walk back in and see what caught his eye. He would then examine it for whether he could use the design elements in an ad campaign he was involved in. Then he copied the ??? Integrity? thought? or whatever of the add and ran it till he received a cease and desist from the company. Never sure he was truly over the line, he knew he could not fight the large companies sohe stopped or changed... Point is scare tactics are always used and copying is always done. By that time he got good exposure for very little cost (since he copied) Stay on the right side of YOUR heart an morals and you should be OK. Otherwise do the dance and take your chance Sled

-

So guys, what areas should be separated from others? Since I have room I want to be smart about it. I like what Mhicks is saying above. I think my first move is a second table to separate any pounding from the rest. stuff gets crazy when I rivet things. I guess my primary table is not sturdy enough. Plus only 2 people have ever used the guest bed in that room so i guess it goes the way of the Dodo... Currently I just "make stuff" and give it away as I practice so I have not thought through "flow" as if I was producing several of a product. I did 7 Key/watch/coin stuff holders (2 tone with a tan and a black leather some with copper, others brass, and some stitched) last night, and 5 mouse pads are glued today awaiting stitching tonight. So... what goes with what? Pounding with cutting? stitching with cutting? Dying with??? Would most agree with this flow? I love rivets (copper in general) so where does the hammering go? Sled

-

I never have that problem, mine is that I can't choose what I really want to say with one. Hee the choice is limited, on my phone I barely try... Sled

-

Welcome aboard from another newbie!! Great help here. Sled

-

There are a few running workshop threads. What I want to know is what is optimum? For instance,nobody told me to have either a sturdier table or a separate area for hammering... Anything not in a bucket screwed down along the back of the table is always on the floor... So if you have some room, whats best? Sled

-

Time to replace the Shetland Pony/Foal

Sledzep01 replied to Sledzep01's topic in Leatherwork Conversation

-

I was hoping to hang a flap of leather over it with one of those... Grrr, cant remember... too lazy to look it up. Let's call it a Tom Jones rivet? you know where it is like a knob that gets screwed on and the leather hole snaps over it... Like a Chicago Screw. Searching now and still cannot find the name. Whew, I know it's seconds there but 10 minutes later here.... Sam Browne Studs...! BUT Thank you for the idea, I had thought of my idea and then forgot it.... Boy thats ugly, watching someone think out loud on a forum...But thats me Sled here is the finished top... anyone want to stop by and build one??

- 3 replies

-

- stitching pony

- clam

-

(and 1 more)

Tagged with:

-

Time to replace the Shetland Pony/Foal

Sledzep01 replied to Sledzep01's topic in Leatherwork Conversation

HAHAHAHAHA!!!! -

Time to replace the Shetland Pony/Foal

Sledzep01 replied to Sledzep01's topic in Leatherwork Conversation

You named my last one... What's this ones name?? Secretariat? Bog Hoss? Sled cant cut straight? Sled -

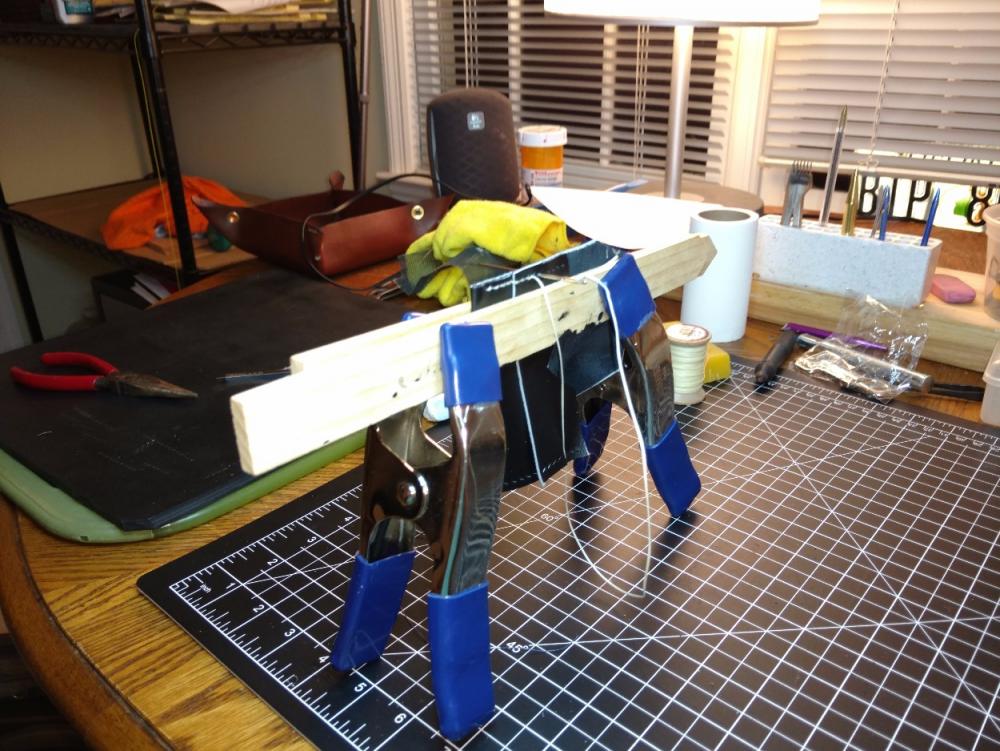

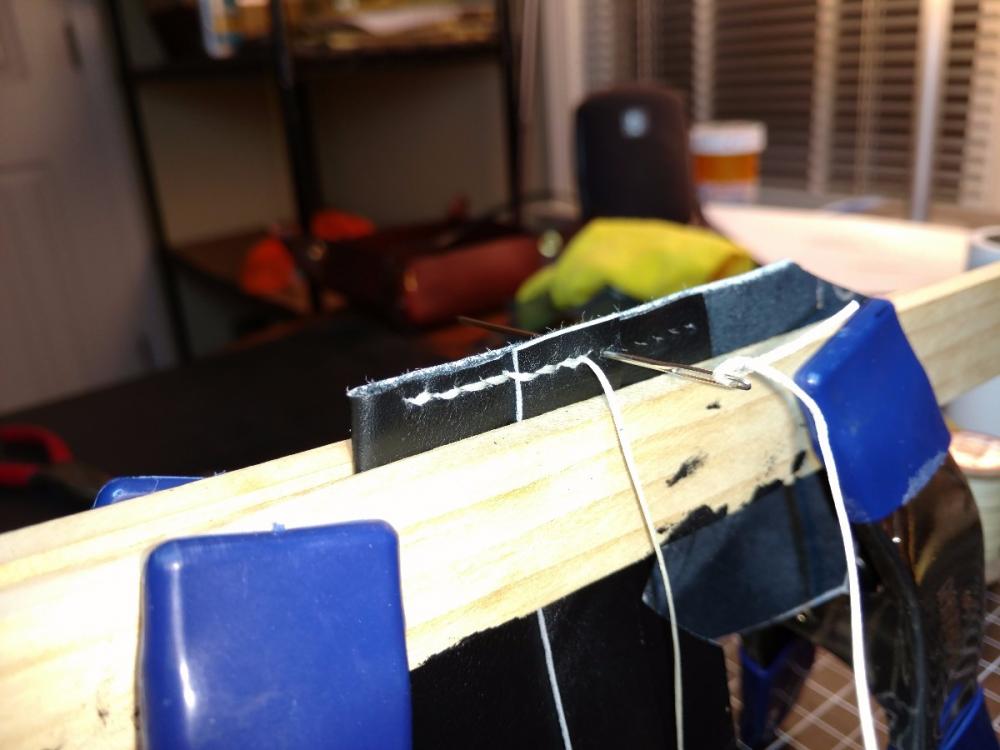

So I have a bunch of wood. I just made a stitching clam (Pics below, not great but it will work) I already have wood cut for another and enough to make at least 4 more kike it. I also want to make 4 (1 for me) stand up clams also. Literally standing on the floor 4ft tall out of 2x6x8 cedar boards. Free wood, a saw, a drill, and router to you... Help for me. I even have a few hinges if you are not particular. Win Win I am tired of drilling an screwing everything to my table to hold it still. Anyone up for a Pony Party? You bring the bolts & HW, I used a 5 and 6 inch in these pics. Here is a thread with ideas I had, and here is what I made. PM me or respond here. No staining involved this way we are done in 1 day. http://leatherworker.net/forum/topic/78885-time-to-replace-the-shetland-ponyfoal/

- 3 replies

-

- stitching pony

- clam

-

(and 1 more)

Tagged with:

-

Time to replace the Shetland Pony/Foal

Sledzep01 replied to Sledzep01's topic in Leatherwork Conversation

And here is what I made. Keep in mind my Brain thinks straight... But my hand does not. you will see that the bottom needed "adjustment" but the top matches pretty good. Yes I will cover it with leather later tonight. I was just excited to share. I will sand the top even before I add the leather. -

Time to replace the Shetland Pony/Foal

Sledzep01 replied to Sledzep01's topic in Leatherwork Conversation

Well my thought is that I have all of this wood. Enough to do at least 4 more like I already made (Pics here later) and I have 3? 2x6x8 pieces of cedar... Cut them in half, add hinges, attach to a piece of plywood to stand on and I would have a 4 foot tall standing clam. Since its almost as easy to make more than one at the same time I was going to see if there was anyone else in North GA that needed one or the other and invite them for a building party. I could easily just make it with a bolt or cam lever across, but your thought on having the clearance inside made me think of this... My plan was to have it to one side (in the middle) of a 2x4 piece of plywood so I could stand on it... and your board off to the right... Just that my creativity wants something done with that cedar since I found it in my basement (I live here 8 years) Besides all of the other wood. Sled -

Time to replace the Shetland Pony/Foal

Sledzep01 replied to Sledzep01's topic in Leatherwork Conversation

Do you think that system would work and 2 4ft tall pieces of 2x6 cedar? What wood would I use for the flexible part that gives the pressure? My creativity wheels are in high gear. Sled -

Time to replace the Shetland Pony/Foal

Sledzep01 replied to Sledzep01's topic in Leatherwork Conversation

That looks great, and the no catching on handles is a good idea. But that looks too something for me, hard to say for sure, I think I would break the thin pressure board. I have a habit of over tightening many things. I do own a TV but do not watch while stitching. I do listen sometimes, but mostly its music in the background. I would consider something like that (Standing and nothing in the center) when I move up to real bags. I have cut enough pieces for 2 clams already, and even found some of the star nuts mentioned above just laying in a tool box. I just needs some bolts for now... Naturally I am already thinking of a way to upgrade it. how do you determine the angle and length of board to use in your design? Sled -

Time to replace the Shetland Pony/Foal

Sledzep01 replied to Sledzep01's topic in Leatherwork Conversation

I have been fighting that for over a year. Her Name is Quinn. she is 1.5yrs old now but still a kitten. if she sneaks in the room anything is game! If I understand YOUR meaning its sand and seal everything? -

Time to replace the Shetland Pony/Foal

Sledzep01 replied to Sledzep01's topic in Leatherwork Conversation

Exactly what I want. Since posting my question earlier I have almost finished cutting 2 out. but when testing my "Girth Adjustment I realized it needs More adjustment I found everything just walking through my house. All the wood, some bolts, hinges. I will definitely be ordering those 2 items you posted, My plan is to create a padded 1x10 of correct girth adjustment. Attached to 2 2x4's with their outer edges made 1/2 round with a router. a 2x4 between with a hinge on 1 of the 2x4 towers, and at the top 2 pieces of 45 degree 1x3 cedar 8 inches wide that I found in the basement. So very similar to yours, but with an 8 inch jaw -

Time to replace the Shetland Pony/Foal

Sledzep01 replied to Sledzep01's topic in Leatherwork Conversation

Whoops I think I want a clam?? Not a Pony. So I would sit on a board on a chair. I do not want to make an entire bench. Sled -

So after trying to stitch a few times with the Shetland Pony (Thank you Thor's Hammer Milinior???) I have decided to actually create something to stitch on. There are many designs I can find online. The question I have is... How wide at the top? All the ones I see are only about 4-6 inches wide. I certainly expect to make mine at least 6 inches wide/long. Should I? or is there a reason to keep it thinner? Also, is there a name for the type of thing that can be adjusted (threaded rod) but then you just lever it up or down and it's locked? I would love to Google that and use it instead of just a wing nut type thing. Also, I you have a link online to one you chose and built and enjoy I would certainly accept that. I have plenty of 1x9's, 2x6 & 8's, 2x4's plywood etc etc I have basic tools, so this cannot be fancy

-

I was downstairs taking pics for something else so... Since many of you made me jealous with all of your tools and Experience ambience I figured I could return the favor by showing you all the room I have for when I need it. These do not show the shed or garage... The first is the next place I will move into. The other 2 are just in case I end up with a successful business (not really trying for that but who knows) That's the next leather doner in the back there

-

I think its more of a Foal, than a pony! Don't make me show you the stack of 6x1's, 6x2's, 2x4's etc down stairs. Any normal person would have built a stitching pony by now, but are any of us really normal?

-

Lets get the honesty out there right now... The pics were taken directly after I created the space. I was jammering on the kitchen table the day before... Yet I had this space with all the furniture and tunes and TV just sitting there. Also, (Ducks head to avoid swipes to back of head) I have a 2 car garage I could use, a 10x16 shed, and a full finished basement with a heavy duty 4x8 table (another thread) Here is my stitching pony and first stitches Its funny, ALL the steps seam like the easy ones on YouTube... Till you try thrm

.jpg.d60258221c476480a6e073a8805645bb.jpg)