PheesOriginal

Members-

Posts

10 -

Joined

-

Last visited

Contact Methods

-

Website URL

www.pheesoriginalgoods.ca

Profile Information

-

Location

East Coast, Canada

-

Interests

Construction, Skateboarding, Travelling, Creating

LW Info

-

Leatherwork Specialty

Accessories

-

Interested in learning about

Business, Machinery (sewing, cutting, stamping)

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

PheesOriginal's Achievements

Member (2/4)

-

Thanks for those links, I've used most of these for odds and ends in the past although I haven't heard of Zelikrovitz they seem to have a decent stock of leather. We use a bunch of different pieces of hardware, probably 100 different sku's between belt buckles, centre bar buckles, double cap rivets, burr rivets, tuck locks, segma snaps, line 24 snaps, trigger snaps, sling lever hooks, fish hooks, key rings, grommets just to name a few - all in four different finishes (brass, nickel, antique brass, black pvd). So yeah, it's going to be a big task replace all of our hardware with new sourcing but we have to start diverting away from BG since the price jumps last year. Appreciate the feedback!

-

Buckleguy has been our supplier for years and although we love the quality, their prices spiked significantly last year. Alibaba has been suggested to me a few times but it’s such a complex platform with SO many options I don’t know where to start or who to trust. Would be open to suggestions of companies to look into on AB who are trusted sources. Does anyone have any sources outside of the usual suspects? We’re in Canada but willing to purchase internationally.

-

Just seeing this comment now after asking you about this same issue in another thread! Ha! Thanks so much for the advice. We got the machine and love it aside from the fraying issue. We have a Kwok Hing binding attachment setup. Any chance I could pick your brain about this modification sometime?

-

Machine stitching failing consistency Adler 669

PheesOriginal replied to Manuel55's topic in Sewing Leather

Hey @shoepatcher, any chance you can provide more info on this? Pictures or a bit more detail on what part you enlarged and how you did it? I have the same machine and I think I have this issue. I’m using smaller needles (I think they’re #120) but my top thread keeps fraying inconsistently. The fray only shows between the take up lever and the needle but I’m thinking the issue is happening beneath the feed plate like you’re saying. Very relieving to see this comment and know there’s a fix. I’ve heard from a friend with the same machine that this is an issue with the machine. It seems pretty shotty for such an expensive machine to have such an obvious issue. -

Hey Elon, I’m looking into these machines for bag making. We do leather and waxed canvas work and need a machine to bind edges with 1” and 1 1/2” bias tape. With pockets, some of these pieces might be fairly thick (3 or 4 pieces of 3-4oz leather plus edge binding). Wondering what your thoughts are on the Adler 669 after having it a while and if you think this would suit our needs? Any other advice from Adler users would be appreciated too!

-

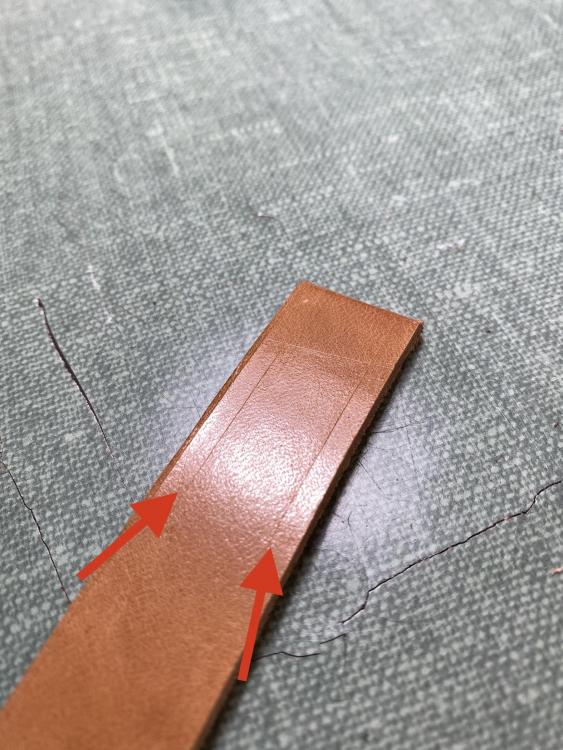

My Easy Edger is leaving lines on the bottom side of the strap where it comes into contact with the feet that press the leather against the blades. I’ve tried adjusting the position of those feet but it seems when the feet are loose enough to not mark the leather they aren’t keeping enough pressure on the strap and when they’re tight enough to keep the leather pressed against the blade they’re marking the leather. Has anyone dealt with this issue before? Weaver suggested I adjust the foot position but alas, here we are. Is this just a compromise people make for the convenience of easy strap edging? I’d just as soon bevel them by hand as to leave marks in my leather. The only straps I use are Wickett & Craig Harness leather which seems to be quite susceptible to this issue. Any advice would be appreciated.

- 10 replies

-

- edge beveller

- weaver machines

-

(and 1 more)

Tagged with:

-

TECH SEW 2750 PRO BINDING ATTACHMENT

PheesOriginal replied to Appaloosa's topic in Leather Sewing Machines

Curious how this binding attachment worked out for you? Also did it take much prototyping fro them to get an attachment that suited your needs? -

I am up against this same issue. Searching all over for a hemmer foot or attachment that will fold 15oz waxed canvas and leather. Contacted sail rite and they said they haven't found one that works yet. If I have any luck i'll post here.

-

Carpenters Tool Belts

PheesOriginal replied to PheesOriginal's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks Webicons, that is a great idea about making modular setups. As I produce a few more designs I’ll definitely consider this. Im currently cutting by hand but looking at making a clicker. The modified bearing press looks like a good inexpensive method but I’d prefer to make one with a swing arm. Haven seen any online aside from custom expensive ones. Looking to make one though.. any ideas on that? -

https://ibb.co/d6ACfz https://ibb.co/dBZG7e https://ibb.co/cPVCfz Hey there, I’ve made a few toolbelts over the past couple of months and have been looking to steer my business in this direction (work gear, pouches, aprons, tool rolls). The design of the pouches are done w the customers as far as placement and size of bags, and little add ons. I’m mostly looking for help marketing this stuff and making it. Looking for tools to help speed up the process, tough materials to make it with, and places to market this gear that tradesmen and women will see it. Have any of you dabbled in this area before? Any help is appreciated. Thanks! -Kyle www.pheesoriginalgoods.ca