canonitr

Members-

Posts

96 -

Joined

-

Last visited

Contact Methods

-

Website URL

http://cdadc.wordpress.com

Profile Information

-

Gender

Male

-

Location

Singapore

-

Interests

Fishing, Photography, Leathercraft

LW Info

-

Leatherwork Specialty

Making leather scraps

-

Interested in learning about

Making nicer leather scraps

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

canonitr's Achievements

Member (2/4)

-

I got Ledafil Super as base coat , and orly bt extramat as edge paint, though I am actually using wuta for the above .. I also have some basco edge coat in clear (https://www.goodsjapan.com/basco-leathercraft-edge-coat-brown-leather-edge-dye-dressing-kote-finish/a-20161) and wonder if I could use it as base for painting as well.. seems to dry to the same as the ledafil

-

Thanks . I couldn’t find the pieces that I had .. but what I did do was get base coat and edge paint

-

Looking for one example.. might have thrown it into scrap pile…

-

This was taken from the internet.. not my edge.. I think the piece I have is chrome tanned too. Though it seems it’s not the type of tanning that is the root cause..

-

a picture i got from the internet.. the lower piece has loose fiber ,,, source https://www.leather-dictionary.com/index.php/Looseness

-

i have already sanded it, but its not actually fiber sticking out, but more of a loose edge..i have tried tokonole (similar) on other projects, and it doesnt really work, though i never actually compressed it after application..

-

What makes a good or bad hot foil machine?

canonitr replied to TestTube's topic in Leather Machinery

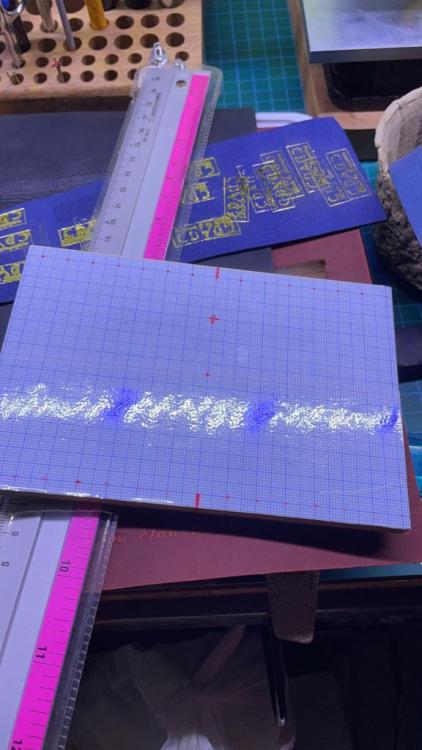

i recently got a hot foil machine from China.. about $170 SGD (~ $125USD) incl shipping or $100 SGD (~$75 USD) for the machine alone , though they have a slightly cheaper, smaller one (with smaller heating element). in fact a complete alphanumeric set (3x each char) cost 2.5 times the machine. the heating element is about 3x4 inch and is bascially a press with the heating element attached. For it's price, everything is manual.. there is no foil holder at all and no markings on the base plate.. What's worse is that the stamping die is connected to the heating element by use of a m5 threaded bar. In order to be able to remove the die, there must be clearance between the heating element and the base plate. However, with the clearance, the stamp is not able to meet the base plate.. the wooden board is used to raise the stamping bed a bit higher, though i have since changed it to a MDF board with graph paper for better and consistent positioning. the back of the base plate has a 1mm thick acrylic piece used as a stopper for the MDF board.. So the question is, is it worth it? Yes.. for my personal use only.. its very manual.. but it serves my need for its price. i would think that for a $1000 machine, you would want something with the ability to change the dies easily (slide in/out) instead of a threaded rod.. have a positioning guide or markings foil holder i spent about $700 SGD ++ for the machine, 8 foil colors, 2 full alphanumeric set (one script one normal), maker's mark, constellation and zodiac signs dies. the dies are cnc brass -

Hi, i'm not sure what's the term for it, so i am just going to use "leather fiber" for now.. basically, when i am about to finish my leather edges, i notice that for most parts, i am able to get the 2 or more layers sandwiched nicely (sanded nice and even).. however, i do get small portions of the edge, that just seem to not be able to be flattened down nicely, and looks like the leather fiber at that part is is uncompressed or loose. any glue or tape at that area is still there, between the 2 pieces of leather, but the fiber just behind the adhesive just loosens up. it happen whether i use contact glue, or double sided tissue tape.. it happens rarely between 2 vegtan pieces, but fairly often if one piece is goat or some other leather (in my current case, its nubuck). the nicer parts can get burnished with edge wax. bees wax or paraffin wax, or more recently with the Crimson OEM fileteuse, but that loose fiber is giving me some headache.. i'll try to get a picture of what i mean later on tonight (my time)

-

Basic question about glueing and stitching

canonitr replied to NeilMott's topic in Leatherwork Conversation

there is a product from columbus that is called rub-rub .. basically its a piece of rubber (raw rubber ?) .. after gluing, u use the rub-rub to, well, rub the squeeze out ... i used to have issue with gluing the soles to my shoes because of the squeeze out making it unsightly.. -

isnt the black stuff kiwi shoe polish ?

-

-

space is at a premium in Singapore, so we build upwards.. when i didnt have the rack, i had stuff all over the place.. the rack was to accommodate my fishing and leather working stuff.. it seems the leather stuff pretty much filled up the rack.. i dont lay them flat.. it's rolled up(have been advised that its better to store in this way to keep fibers tight (??)) the widest hide i have is maybe 4 1/2 ft wide, so it sits okay on the rack. have about 6-7 rolls of full/ half hides

-

i got a 4 tier, 4ft long, 6ft high boltless rack to store my hobby stuff, and 1 tier is dedicated to laying the leather horizontally..

-

i bought small pieces (20 x 30 cm) of crazy horse for about $6 (SGD) each .. waiting to receive as I accidentally chose sea freight from China.. now most of my hardware (not tools) come from wuta.. @BR79compare goodsjapan's pricing to leathercrafttools.com .. both are from japan .. have similar stuff.. but pricing differs as goodsjapan seem to factor in shipping into their pricing already, whereas LCT doesnt, and allows you to choose EMS or normal at the end

-

Sticking with chisels instead of pricking irons...

canonitr replied to scrapyarddog's topic in Leatherwork Conversation

i like my crimsons.., not sure if they are chisels or irons, though crimson calls it irons..