DanishMan

Members-

Posts

303 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DanishMan

-

Hi Constabulary I will try to contact them The manual is available in German, but I would prefer it in English. Cheers

-

Dear friends I am looking for a manual for the Quick Rotan P70SE motor in english (all three parts). Does any of you have one, I am interested in buying it. Cheers Danish Man

-

Hi Mimicry Unfortunately not. Cheers Søren

-

Take a look at this. It helped me, when I was changing the knife of a Fortuna 520. https://duvallleatherwork.com/fortuna-sas-band-blade-replacement/

-

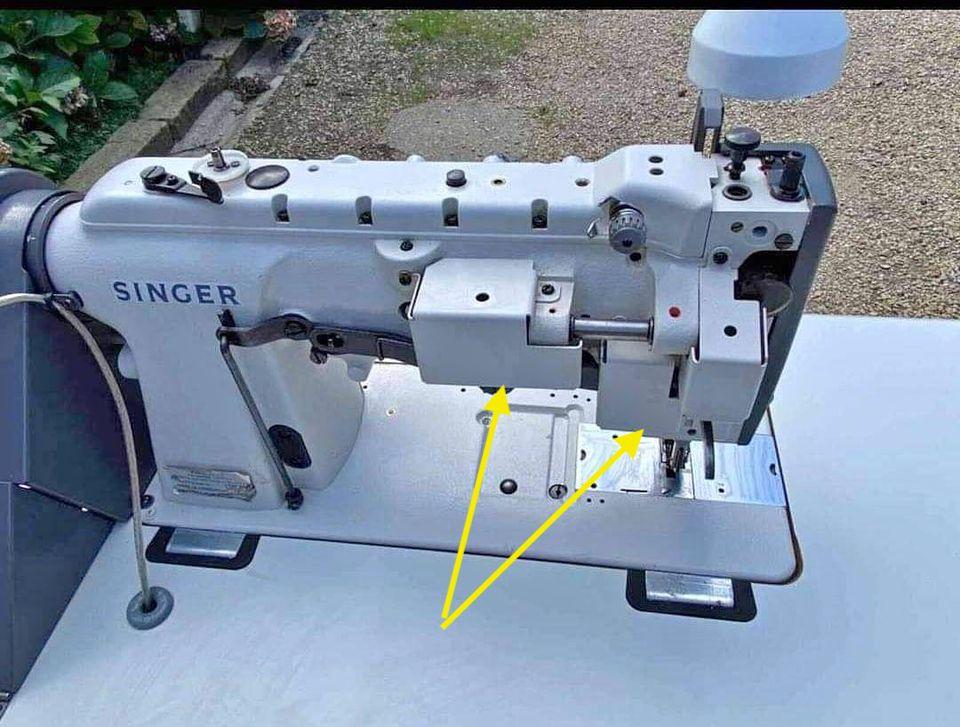

Dear Friends Just found this Singer 211 for sale on Ebay. Anyone who knows, what these two boxes are on the back site of the machine? Kind regards DanishMan

-

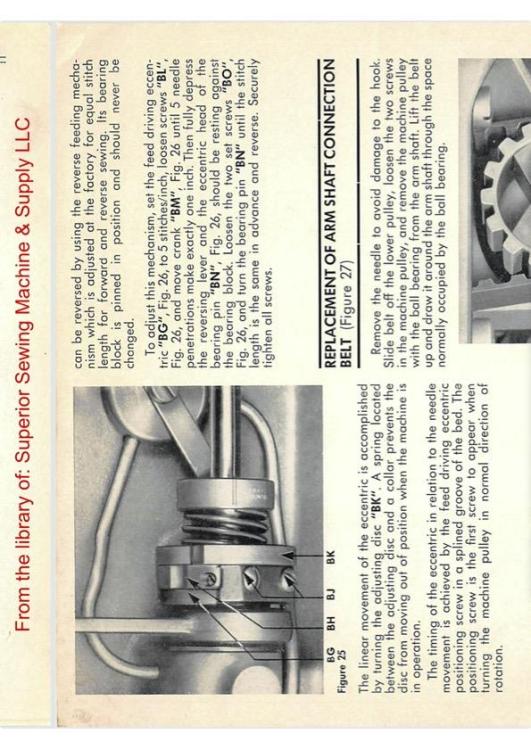

211U566 forward / reverse balance

DanishMan replied to vblouindemers's topic in Leather Sewing Machines

Hi I have the same problem as you, and I can not figure out the service manual. I can get 8 mm forward stitch length and 5 mm reverse. But if I reduce the forward stitch length. i.e. by 2mm, the reverse stitch is also reduced. Is that just how it is? Cheers Danishman -

The machine maximum forward stitch is 8.4 mm, and the reverse is 5 mm. But when going to shorter stitches - like 5mm forward - the reverse stitch is also 2-3 mm shorter. Is the machine supposed to have equal forward/reverse stitches when 5mm and below???

-

Dear Friends I have been renovating an old Singer 211G566 for the past weeks. It is a very nice machine, and I also have two 211U566's in the pipeline. The manual says, that the machine has a maximum stitch length of 8.4 mm, but is limited to 5 mm in reverse. I simply can not get my head around how to adjust the reverse feed. The manuals are not very precise, and I can not get it right. Anyone here, that knows how to do this? Kind regards DanishMan

-

Dear Friends I am working on a PFAFF 331 9B. I am puzzled about the maximum stitch length. It is sewing with about 3 mm stiches. I was expecting 4 mm stitches. Anyone here with knowledge of the PFAFF 331 9B? Kind regards Danishman

-

Thank you Quade

-

Hi Constabulary Normally I do not take sewing machines fully apart, but I have been looking for a Singer 211, that I could disassemble fully, as I have limited knowledge of these machines. If it turned out, that I brake it, I will salvage the parts for later projects (I have a Singer 211u566 in the pipeline). It has been going pretty well, and just now, I realised that the dodgy feed is related to the reverse lever. I will sort that out on Wednesday. Cheers Danish Man

-

Dear Friends Two weeks ago, I bought a Singer 211G566. It was in okay condition, but I decided to take it apart to get knowledge about the machine. Now I have put it all back together, and I have started with the adjustments. One thing, I can not get to work is the feed dog timing. I can time it reasonable, but when trying to change stitch length it messes up everything - and does not change stitch length at all. Is there any basic adjustment of the "adjusting disc" when installing the feed eccentric? Kind regards Danish Man

-

Hi I have seen the one in Australia, but with thoughts of tax, fees etc it might be too complicated. A good friend of mine is often in the US with his job. He has brought a few items back to me, when needed. Cheers Danish Man

-

Dear Friends I am looking for a reverse spring for a Singer 211. The spare part number is 267415. Please contact me, if any of you have one for sale. Cheers Danish Man

-

Dear Friends I am a curious about the Adler 205 sewing machine. Is the 205-370 the only variant with walking foot - or does some older variants also have walking foot? Kind regards Danish Man

-

Thank you Constabulary. One little question more. When the feed dog emerges it lifts the presser foot slightly. This will move the food lift bar on the back of the machine continuously. Is this normal? Kind regards Danishman

-

Dear Friends I hope you are all well. About half a year ago, I bought an Adler 204 at an auction in Denmark. It was in pretty good condition and the price was low. It turned out, that the various motor had to be scrapped. The motor started up, but when pushing the foot pedal, the cludge did not engage. Now I will fit a strong servo motor to the sewing machine. I like this better, though I have had to abandone the pneumatic foot lift. I will have to sort out how to make a manual presser foot lift. One thing, that puzzles me, is the presser foot. It appears to be fixed and to have no movement at all. Is this right? Kind regards Danishman

-

Dear Friends I am looking for an instruction manual for a Camoga C300. Anyone here, that has one? Kind regards Danish Man

-

Thank you Jonas My guess was 50 kgs. A few months ago I put a hot press machine into my car - weighing 70 kgs. Heavy duty stuff. Cheers Søren PS - It is a 204-64

-

Dear Friends I have bought an Adler 204 at an auction in Denmark.. I am going to pick it up next week. Any of you know how much the machine head weighs itself? Cheers DanishMan

-

Thank you Bob

-

Dear Friends Yesterday I found an Adler 204 at an auction in Denmark. I won the auction, and now my quiestion is whether an 204-64 has reverse? Anyone who knows? Cheers Danishman

-

Washing of machine and parts

-

After parting out the 543, I decided to take the 145 apart as well, as it was immense dirty. I use a water based industrial cleaner for washing all the parts and the machine itself.

-

First thing was to part out the PFAFF 543. Not difficult, when you do it in the right order. The most difficult thing is always to remove the main shaft. Before attempting to remove the main shaft - the take up lever must be removed. It is pretty easy, but it can only be removed in a very specific position. Regarding the main shaft, obviously one need to loosen all the screws in the gears, eccentrics etc, but still it is often very difficult. I have have found, that over time, the outer part of the main shaft often has small burs, gouges etc from years of use, in which the hand wheel has been on and off several time. These small damages makes it virtually impossible to remove the main shaft. They have to be removed first. Use a fine file or sandpaper. Using another main shaft - and a rubber hammer - prevents burs at the end of the main shaft.