-

Posts

972 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by gtwister09

-

JRedding/Romey, I had to chuckle :D when reading these posts due to the fact that all three of those tidbits and more were conveyed to me by my Dad or other ranchers. In fact I can remember one older hand (actually he owned several ranches but you would have never known it) asking a new hand if they used that nightlatch and he said, "Yes I do every now and then." Well he rode over and with his pocket knife cut it off and said to him, "Ride your horse not your saddle. I won't have you hurt riding with me." That same day he also modified his rope strap as well. Regards, Ben

-

Saddlemaking- Opinions on Instruction

gtwister09 replied to Ron's topic in General Saddlery Discussion

Got it exactly. You want to be known for the function (i.e. great fit and made well - not just for nice tooling). The point that I was trying to make about Jim L's knife was the the carving was extremely nice but the stitching wasn't up to the same standard and the knife fell out of the sheath too easily. In this case a portion of the art form - carving was great but the function was less than desirable. Likewise don't have you confused with another Dave. Regards, Ben -

Saddlemaking- Opinions on Instruction

gtwister09 replied to Ron's topic in General Saddlery Discussion

Amen to that David. Something that is near and dear to my heart. Using the many industries and careers to further another. Leading people or an industry through change is always difficult even though change is inevitable. Regards, Ben -

Saddlemaking- Opinions on Instruction

gtwister09 replied to Ron's topic in General Saddlery Discussion

That's right in line with my comment.... (I have seen so many people who are certified in databases, operating systems and networks yet they can't put that learning to work to correct problems and design. Not all of them mind you but enough to know that the certifications are no guarantee for fitness.) Just because they were trained and certified these weren't any guarantee that they could put the information to use or practice it. You have to apply and develop your own style. These are just the foundational steps. My first saddle I took pieces of information from Hooper, Jones and Yates to build the first one. I mainly used Hooper but I used Jones because he was the one who had a leather ground seat and that was what I wanted to use at the time. Just a case in point for developing your own style and methods. In business process reengineering they call this methodology a couple of things (1) information reuse or (2) benchmarking - another term for stealing shamelessly. Regards, Ben -

Saddlemaking- Opinions on Instruction

gtwister09 replied to Ron's topic in General Saddlery Discussion

Ron, Philosphy comments are dead on. It is a lot different from the working end of the saddle or any other career. I presently work as an Independent Executive Consultant in Information Technology. I have seen so many people who are certified in databases, operating systems and networks yet they can't put that learning to work to correct problems and design. Not all of them mind you but enough to know that the certifications are no guarantee for fitness. They understand the hows just not the whys. If you understand both the how and why then you can also evaluate new techniques as well. With that being said, I am a firm believer in a library. I read once that, "A person is only as good as his library." There is considerable truth to that statement assuming that the books and videos are used, read and watched. This is especially true for saddle makers because there was limited ones available. However there have been more and more books and videos available over the years. The same holds true in the engraving, machining and woodworking worlds as well. You must study in order to improve. Some do it like Dave did by moving around and working under some of the greats. Others have to glean through other methods like books, videos and other methods including discussions like these. Start a library and add to it constantly. Unfortunately many of the books and videos associated with saddlemaking are expensive. Good work is rare and it takes a lot of time, effort, photographs and such (don't forget $$$$) to publish either books or video. However remember that not all books or videos represent high quality or good work. One such saddlemaking one that comes to mind is Lee Rice's information on "How to Make a Western Saddle". You will learn to discriminate between what is good and what is not, Try to incorporate some of what you see into your own work. This is the best way to grow. On another note concerning a good library... it can supply you with an endless source of inspiration as well as a means of researching style. I have the luxury at this time of being able to purchase a library for some of my passions in woodworking, saddlemaking/leatherworking and engraving/bits and spurs. It is also a double-edged sword on the other side in that it limits my time in being able to constantly pursue these passions. I started gathering saddlemaking books almost 30 years ago and haven't stopped yet. (as far as saddlemaking I have almost all of the books out there except for Beck's and I have almost all the videos from well know people like Harwood, Gomer and Watt to less published ones like Harry King). In fact the last few years have created a lot more information with videos and books as well as the internet. Once you identify an area of interest then utilize the power of the internet to gather information on that subject with search engines like google, wikia and others. I capture pages and photos from people's web sites using Adobe Acrobat but any PDF creator can do that. Don't overlook the power of forums like this one either. There are ones for bits and spurs, knives, metalworking, computer controlled machining, welding, shoe making and list can go on and on. Utilize them because you can glean a lot of valuable information that is close to being priceless. Save the information and store it away in order that you can utilize it later. This is not to say that the wealth of knowledge that you can gain from actual work with a saddlemaker wouldn't be GREAT. It would have been wonderful to work alongside some of them. I know from talking and developing friendships with some of them that they were a wealth of knowledge just in talking through a project and listening to them. It is just that many of us are unable to do that. Regards, Ben -

A few more Sheridan practice photos

gtwister09 replied to Chuck's topic in Floral and Sheridan Carving

Chuck, Cool on the tools. As always the right tool for the right job. Regards, Ben -

Not the only one Johanna. I too know him via his work. By the way he has GREAT business cards as well. Steven will be well served with his services. Regards, Ben

-

I like it! Thanks. Regards, Ben

-

Saddlemaking- Opinions on Instruction

gtwister09 replied to Ron's topic in General Saddlery Discussion

Interesting comment given the story about the knife case that Jim L. made (in another thread) especially in light of the functionality and stitching. Regards, Ben -

Saddlemaking- Opinions on Instruction

gtwister09 replied to Ron's topic in General Saddlery Discussion

Ron, Not Bruce but Tandy Leather Factory is about as good as it gets unless you can spot a set on eBay a little cheaper. Harry's daughter is selling his manual now for somewhere around $80-90. I would really agree with Bruce on Jeremiah's videos. I have all of the ones that Bruce has mentioned as well as some by Cheaney, Gomer and Adal/Conway and agree with his comments wholeheartedly about the videos he mentioned. Regards, Ben -

Quick question.... What did you do around the 40th Anniversary? Regards, Ben

-

Let me be the first to welcome you aboard. All nice work! Saddle looks very nice. Knife work everywhere looks very nice and tooling looks great. I like the lines of the square skirts as well. Quilted inliad seat is a little unique as well. Once again welcome aboard. Look forward to more of your work. Regards, Ben

-

A few more Sheridan practice photos

gtwister09 replied to Chuck's topic in Floral and Sheridan Carving

Chuck, I agree about the artboard. It will surprise you. The artboard will give you some more depth on the beveling and background. I would also consider smaller mule feet, backgrounding and definitely smaller veiners. I'm not sure that I would have chosen a checkered shader for the flowers but that is a preference. However, I would also thin the width of these shaders down as well (especially for the flowers). Study the width of actual Sheridan shaders and you will see that they are thinner. Others have already discussed the decorative cuts. On decorative cuts try not to cut across or into the flower center. Now the rope....that combination looks pretty good. I have a beveler modified to do that but it's great to know that Barry has one that comes fit to order (less work that way). Keep up the work! Smaller designs always present their own set of problems as you already stated and know. Regards, Ben -

Luke, I liked them. If you want to test drive before you buy then check out Smartflix. Bianchi Western Holster Making DVDs Regards, Ben

-

Dave, Here's another place that sells HDPE (if that's what your looking for). I have used them before. Of course if you can find a local dealer it would help with shipping. Interstate Plastics There is also LDPE. If I remember right from my manufacturing days there is only 3-5% difference in the density rating. I think that the HDPE os 0.95 or 0.96 whereas the LDPE is 0.91 or 0.92. I can't remember exactly. Regards, Ben

-

Marlon, I like them a lot. In fact Bob Dellis first turned me on to their blades. Bob liked wide straight blades. I have never liked them much myself but he also told me that they were some of the best steel that he had ever carved with so I talked with them and found out that they had 1/4" and 3/8" blades. Well the rest was history. I have tried Bob Beard's and Chuck Smith's as well. I have lent my Bob Beard knife and blade out to a person that is just starting. As far as barrels.....both barrels are 3/8" fine knurl 1.5" long. The blades that I purchased with them were a 1/4" angle fine detail thin (5/64" thick) and a 3/8" straight thin blade. I also bought a 1/16" beader blade. I pulled the 1/4" angle fine detail thin and started using the Peter Mina modified Henley for thinner material. I liked the Peter Main one better (it seemed to open the cut of the lighter leather up more). If you PM me offline I can put you in contact with someone that usually buys a large lot and get's a discount each year. That is how I bought mine (quite a bit of savings that way). Regards, Ben

-

Fair enough but it shows people what options they carry for the barrels and blades. Regards, Ben

-

Bruce, WOW! That was a wealth of information. I was thinking about doing that as well in the future. I will have to keep this information. Thanks! Regards, Ben

-

They do have a web page (not site) on tripod. Henley Blades & Swivel Knives I have a couple of their knives with blades as well as a couple of blades that they made for Peter Main. Regards, Ben

-

Hmmmm...... Here it is. On another note concerning the crease versus cut groove. As bcurrier stated, the difference doesn't amount to a hill of beans on most applications. However here's some food for thought. If you use that logic no carving that cuts the grain should ever be done on a piece of leather namely swivel knife cuts. Just something to think about. I know that I heard some old saddlemakers give the same logic in choosing used saddles with basket stamping or ones with floral caving. This is one of those function things and many are very strongly opinionated about the subject. Regards, Ben

-

Semantics...but there is no actual groove cut into the leather only a crease. (Kind of like how you say potato or tomato) Regards, Ben

-

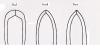

Bruce, Ken is no longer making stitching horses. He mainly made harness makers stitching horses and not saddlemaker's stitching horses. Ken's jaws were generally too thick at the top and didn't allow you the ability to truly do fine stitching. The jaws should be worked down so that you can get your knuckles in close to the work. Saddlemaker's stitching horses will have the jaw closing mechanism below the seat whereas the harness maker's stitching horse will have the jaw closing mechanism above the seat. There are a few variations of the saddlemaker's stitching horse including one that has a slot cut in the front of the seat in order to allow larger items to be stitched. Saddlemaker's stitching horses usually have 16-18" of clearance in them. By contrast, the harness maker's stitching horses have less jaw space due to the strap going through the jaws to tighten them. These will limit you as to the size of the projects you can put in them. If it's straps or billfolds you stitch, these will work fine, but larger items will not fit (about 6-8" clearance). I am including an example of stitching horse jaw profiles and what they should look like from bad (absolutely not to be purchased) to best profile. Regards, Ben P.S. I am a groover front and back except for very light leather and then I use a creaser to create a fake stitching channel.

-

As mentioned earlier, Hidecrafter has some PX series tools that have some "steep" bevelers that are checkered. They aren't smooth. These cost a little more than Craftools but definitely less than Custom tools. They are quite good. Regards, Ben

-

YR, I'm with Bruce on the cantlle/seat. I even pulled the pictures down and tried to zoom in. Still looked like it might be separate pieces but that could be the pictures. Welcome aboard! Regards, Ben

-

I have had success with clear shelf, 3M and Office Depot carton tape. The ones that I have not had success with are all brands of label tape (tried 3M and others - way too sticky). I have not had a lot of success with masking or painter's tape. In fact I would steer clear of any label tape, duct tape, masking or painter's tape. They either don't limit the stretch all that way or they are way too sticky. As far as curl up on edges, I have not had that problem. I layout the tape overlapping a small amount with each piece of tape in one direction. I make sure that the first layer of tape is slicked down with a glass slicker. Next I usually layout another layer of tape at about 90 degrees to the first layer of tape. I have not had any issues with the edges curling even with basketweaves. Bruce hit upon the fact that the basket weave and geometric stamping will definitely have much more stretch that a floral carving. This is so true! There's a lot more of the the leather being worked than with the floral. A couple of the older saddle makers told me if you had a choice for a working saddle to always choose a basket stamped saddle over a larger floral carved saddle because the leather would be compressed more on the basket stamped. Their thought was that the compression of leather fibers extended the life of the leather. Regards, Ben