-

Posts

1,330 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by PastorBob

-

-

I love the simplicity of the design and the carving. How they (chisels) get bent is beyond me. My first set was from Tandy and lasted about 2 months. I ended up getting the Weaver chisels. they are nice, but too short for my hands. ended up making a handle out of wood dowel rod (1.25" diameter) that I can move from one chisel to the next. Works out pretty good. So far, they are holding up and its been several years.

-

St. Michael

in Art

13 minutes ago, immiketoo said:This was done with a stamp, not hand carved but I did crisp it up with a spoon

Very fine work. Very tedious to crisp, I am sure.

-

Incredible workmanship. the holster has really held up well. I love the double stitching too. Nice job!

-

St. Michael

in Art

I thought it was done with a stamp. Did you carve the design @immiketoo?

-

My area is not nearly that big. You will definitely be able to store your rolled leather under your cutting table. I placed a work bench (2x6') against a wall and use it as my work space. On the back edge, against the wall, I have my wood blocks holding my stamps and other round metal handled tools. On the wall, directly above my blocks, I have some 1x4x6' pine mounted with leather loops to hold my edge bevelers, round end punches, etc. Above that are 3 shelves 1x15x4' I store my threads, and larger bottles of dyes, glue can, etc.

Beside the work bench I have some of those plastic stackable drawers for hardware, misc tools. I also have some under one end of my workbench for work in process and small pieces of exotic leathers. On the other wall is a 3x6' folding table my wife uses for her sewing machines.

-

Anxious to see your progress....practice, practice, practice. Now you know why really good leather work is priced the way it is.

-

Very nice work. Getting any leather work done? LOL.

-

Wow! very impressive. You're right...the gold addition really does make it pop. Kudos!

-

24 minutes ago, JayEhl said:

I like the art work and admire, too, anyone who can put such detailed finesse onto leather. I've always painted my colors before I put on a resist and antique. Not sure if that is the right order/process but figured it kept the paint/dye from rubbing off so easily? Just curious.

I tried painting a piece prior to adding supershene as a top coat, only to have the paint smear all over the piece. When I inquired of the guy at a Tandy store, he said he always paints last, then applies a spray coating, instead of a rub on. That seems to be working for me. The spray coat I use is Saddle Lac. Expensive, but seems to go a long way.

-

Man, you do nice work. So clean!

-

4 hours ago, Guest Xig said:

Hi.

Why my leather is so soft But the leather I see in the tutorial videos is not like that?

My leather is so soft, that its edges cannot be rounded with a beveler.or it is the cheaper veg tan leather that varies alot in thickness and you are edging a thinner piece.

-

Wow. Nice work. How do you get it in the sheath? Looks like the top part would prevent it from going straight into the sheath?

-

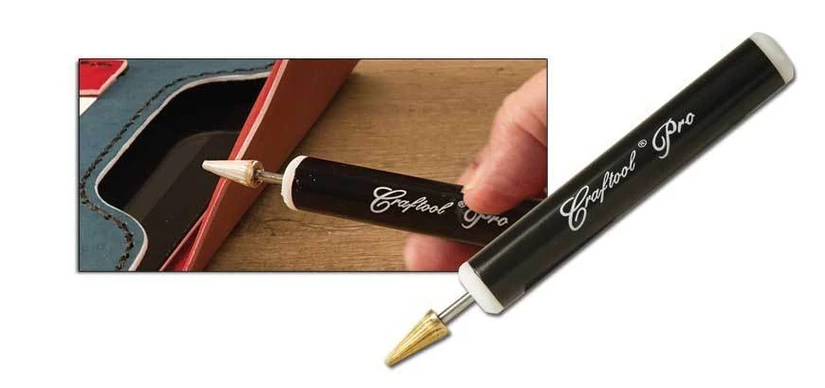

edge applicators....I like the simple one from Tandy. Nice work on holder. Amazing how much a routered edge changes a simple block of wood to look fancy.

-

i am still on the fence. The machine is close by...just spending that much money on a hobby, versus hand stitching. the more I think about it, i will probably pass.

Thanks for all the help and timely advice.

-

6 minutes ago, kgg said:

Does it have a servo motor if not add at least $150 to the price you are paying. Without photo's that shows the overall condition and detailed ones of the thread path and bed, getting an answer is going to be difficult. If the machine is in mint condition no missing parts, no thread worn gouges in the thread path tensioner's, no path worn off the bed, servo motor and most importantly sews properly then I would.

kgg

I can't tell much from the pics...they are from far away and don't really show much. i will call and if I find out anything I will share.

-

3 minutes ago, Wizcrafts said:

Yes and yes. It is an excellent machine for sewing leather up to 3/8 inch, with thread sizes up to #138 top and bottom, or #207 top and 138 in the bobbin. It is just a step down from the top of the line LU-1508N and NH.

Thanks!!!! Is is a good price for a 2007 model?

-

This will be my first sewing machine and don't know enough to be dangerous. I found a Juki 1541S with a walking foot. The owner says less than 100 hours. $1200. Is this a good price? Will it sew 12 oz. leather okay? Thanks for all your help.

-

Thanks for sharing the photos. I like the basketweave and stars on the one. Something to consider when basket weaving...to ensure there are no unfinished basket weave stamps around the edge, follow up with a border stamp encapsulating the entire area that has been basket stamped. It will literally look like the basket weave continues under the border stamp for a really neat affect.

Do you have the actual firearms now so you can make a pattern? If so, I would definitely use them. 10cm is about 4 inches. That seems like a lot. if you don't have the firearms, based on the pics, you could probably add 1/4" to each side(1/2" total) of the flat cut piece. So yes, just extend the width and not the length of the piece.

-

I have never worked with "oakleaf" veg tan, but do know if there is no top coat (pro-resist, supersheen, etc.) natural veg tan will absorb the oils from one's body when making contact. It will get darker as you mentioned, over time. Not sure about the greyish color you are speaking of. From the pics it just looks like normal wear marks. What process did you use to slick the edges? Gum Trag? Tokonole? water?

-

it was $300 in your original post. How is $350 a drop? LOL. Are the tool holders included?

-

Looking good.

-

Thanks @LatigoAmigo for fixing the photo. What process did you use to dye the belt? Dipping, dauber? Any top coat applied like Super Sheen? I would think it's not enough dye or like you said, no NFO (neatsfoot oil) applied.

Welcome to the forum!

-

the holster did get to dry overnight before shipping. It looked great. After I mailed it, guess what my wife found in my inventory bin? You guessed it, the holster I thought I had in inventory. All is good. Off to the next build. Thanks for all your insight and advice. I do like the drying cabinet idea to speed up the process. I am using Pro dye so it seems to dry pretty quickly compared to Eco-flo products.

-

13 hours ago, Minnesota said:

Sorry about the delay. My niece claimed the bag the moment she laid eyes on it. I had to get it back from her to snap a couple of photos. The bottom is all one piece folded length-ways. The two ends each have a notch cut in them so that the ends could wrap around, be stitched together, and voila! A bag is born.

Thanks for sending. i will have to take a crack at it one day. Unfortunately my scrap pieces are less than 6" x 6", anything larger i use for projects. Will have to bite the bullet.

Finally made something for myself

in Archery Quivers and Bow Cases

Posted

Beautiful!! Nice craftsmanship! Is it deer hide around the arrowhead as well?