KillDevilBill

Members-

Posts

61 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by KillDevilBill

-

That's what I'm thinking, but don't have all the details.

-

-

I think I got it figured out. Needs a little tweaking, not crazy about the buckle but pretty happy with the results. Pattern is available for free if anyone needs it.

-

Don't know about Ferg, but I'd definitely be interested!

-

I just bought a kangaroo hide. Wow. Although a little pricey, this is going to be a game changer for my wallets! Great stuff, and I haven't even used it yet!

-

Has anyone had experience making watch fob straps? Seems pretty straightforward, just a mini belt. I'm confusing myself thinking about how they're folded, and where all the holes go. I'm also wondering if/how to get fancy with them, not much room for tooling. Suggestions on leather type?

-

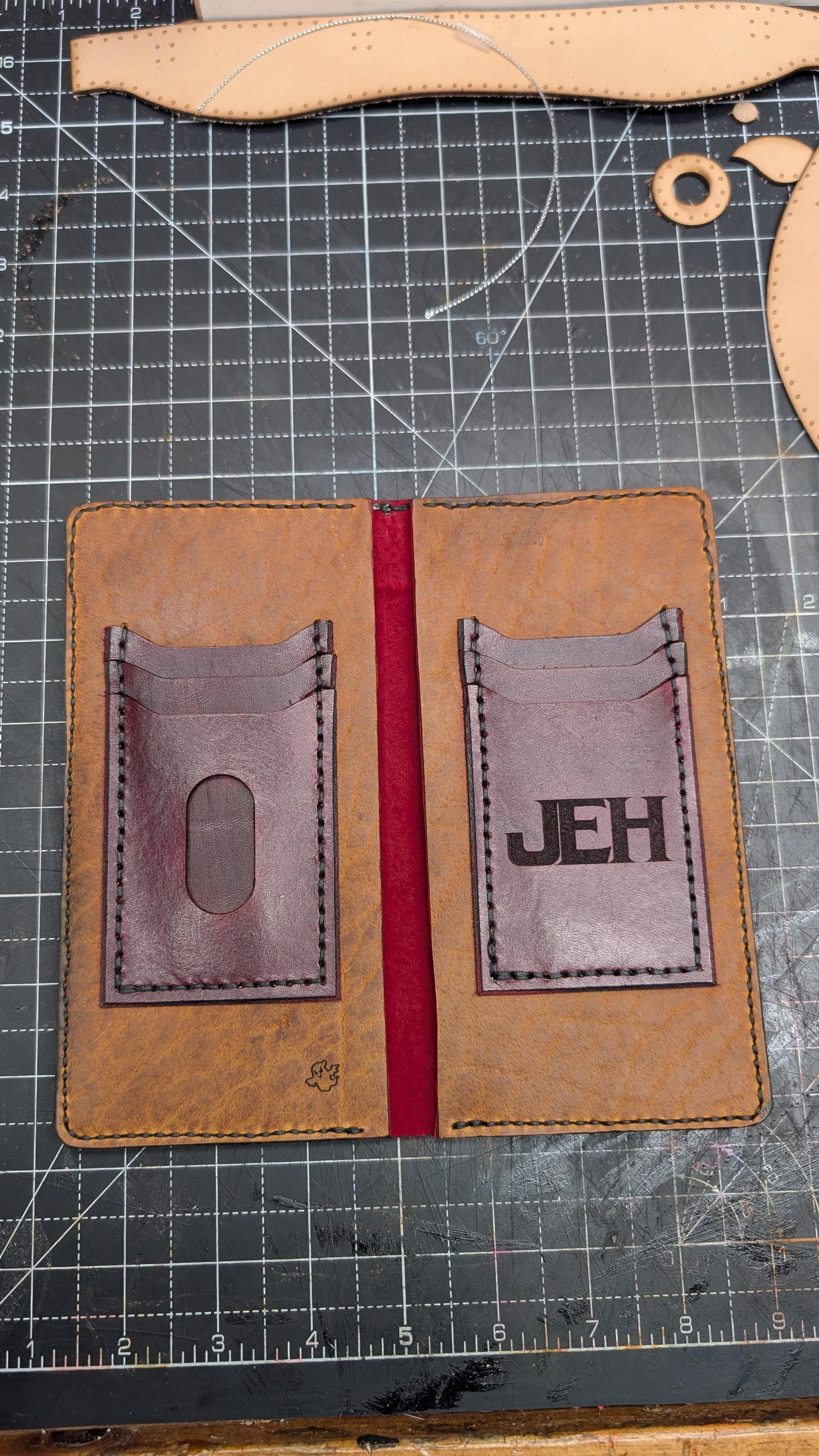

Decided to update/upgrade my own wallet. My own design, version 2.0 Hand tooled, hand stitched as always. Was trying to make it look like an old tractor with the dye/paint. Didn't come out like I had it pictured in my brainus, but I'm happy with it. Questions and comments are always welcome.

-

I've been seeing a LOT of these "minimalist" wallets. Screenshot added for reference. Not my style, I'd probably never build one, but how in the hell do they make them so thin? I'm obviously doing something wrong because my wallets are fat. Well, comfortably plump. This is 4 layers in the pic, and it looks like barely 1/8" thick. I understand it's pretty thin leather, but is there a certain way to cut the pockets? On the edge of the stack, it only appears to be 1 or 2 layers thick. I'm listening.... Learn me something. Lol

-

This was one of those "hurry up on Christmas morning" projects. New wallet for my mother-in-law. I was terrified of tooling the hummingbird, so I kept putting it off, until I couldn't any longer. I need to learn how to add card slots without making the wallet so darn thick. I see wallets with 6 card slots that look great. I haven't figured that out yet. 4/5 veg tan outer with real gator accent, pig suede lining, "peanut" bison dividers, 2/3 veg tan pockets. Bismark brown dye, black acrylic antiquing.

-

This is pretty cool. Blade shape alone makes that one a challenge. Looks great!

-

This is fantastic. Nicely done!

-

New sheath

KillDevilBill replied to KillDevilBill's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Knife is in Washington State, I'm in Ohio I honestly thought about more of a bevel, have a new unused beveler.... I was afraid to screw it up. -

Customer wanted something budget friendly and not too fancy. Part of a gift to his father. He made the knife, asked me to make the sheath. I found out that both he and his father are veterans of the 82nd Airborne. This is the first sheath I've made without having the actual knife. Customer took very nice precise measurements, and good clean photos of the knife. I really like the natural grain on the front. Can't see it in the pics, but the antiquing laid down in there nicely. I just hope the dang thing fits!

-

Thank you!

-

Finished up a phone holster, came up with a good idea by accident. Kinda put the logo a bit too high, didn't want the strap to cover it, so I flipped it over and secured it to the back. So now I have an "ejector strap" which works out kinda nice!

-

I want to see this when it's done! Cool project. I'm gonna go measure my pens.....

-

I'm gonna go with Dwight on this one. Very similar to how I line my holsters, and as a bonus I may have just learned something. Holster or not, just even a test with some scraps on the bench, I can't even imagine a single layer being stronger or more durable than 2 or more pieces making up the same thickness. Multiple pieces have the grain going in multiple directions, then the glue adding a bond. Just my $.02 and some good reading in this thread. Thank you!

-

That's a fantastic idea! Thank you!

-

I should have clarified in my first post. This old gal's working days are OVER. She's a retired garage queen now. I'm not looking to rebuild the pulley, just want to make a nice leather "show cover" for it.

-

The wheel is staying as is. Taking it apart would leave a HUGE mess. It's actually made from paper! It acts and feels like wood, it's nailed together at the factory (79 years ago). I'm liking this Dwight! Got the brain wheels turning.

-

This is a personal project, not a customer. I'm "restoring" my old tractor. It's almost mandatory that it has a leather seat, but I also thought it would be cool to wrap the belt wheel in leather also. My first thought was to stack rings on so the edges face out and burnish the heck out of them. That's gonna take A TON of leather, wheel is 6" diameter. Next thought was flesh side out and burnish, but I'm not sold on that. Right now I'm thinking tooled with the "IH" logo facing out. Just wondering what the talent here comes up with. Looking for ideas! Thanks!

-

I thought I was the only one that obsessed over such things. Lol This is slick!

-

I wouldn't carry such a thing in my pocket, but customer is always right! I had fun with this one. Not much to it after the design and layout is done, but that was the fun part of this one. Sewing was a challenge, and learned a few things. Double stitched on all the corners. Who doesn't need more sewing practice? Lol

-

Desert bighorn holster is finished

KillDevilBill replied to DoubleKCustomLeathercraft's topic in Show Off!!

This is classy! Nicely done!- 15 replies

-

- desert bighorn

- holster

-

(and 1 more)

Tagged with:

-

Choosing durable dog collar thread... linen, Nylex etc...?

KillDevilBill replied to LakeOtter's topic in Sewing Leather

Yeah, what he said. I'll add my thoughts on the groove. If you're making padded collars, the stitching is no longer decorative, it's structural. You mentioned the inside will be protected by the lining, so I would absolutely groove the outside to protect those half of the stitches. I only do straight stitches (my brain shorts out when I see the ugly diagonal stitches. Just my opinion!) and a nice tight stitch in a groove looks classy and clean. If I'm building a hunting collar, absolutely groove even if it's decorative. I've had ZERO issues with Tiger thread. I've had dogs tear the leather but the stitches held up. Good luck!