Search the Community

Showing results for tags '111w'.

-

Hello all, and Merry Christmas: I was hoping to get some input on whether I should go for a 111w155 or a machine that is either a 112w139 or 140. I have done as much research as I can, and I know the 155 is a great first leather machine. However, the 139/140 is cheaper and possibly in better condition. Parts for the 155 seem more readily available, from what I can tell, but if the 139/140 is going to be more useful, I would consider it. The 139/140 is a dual needle, vertical hook lockstitch machine with compound feed. If it's a 139, it has alternating pressers; if 140, I'm not sure. I would mostly be looking to use it for fairly thick belts (ideally up to about 12 oz of pretty stiff leather). If I can do a little bit of bag work as well, great; if not, that's fine. I work almost exclusively with vegtan. At any rate, just looking for votes/tips/other considerations. Thank you all in advance. ~Lawrence

-

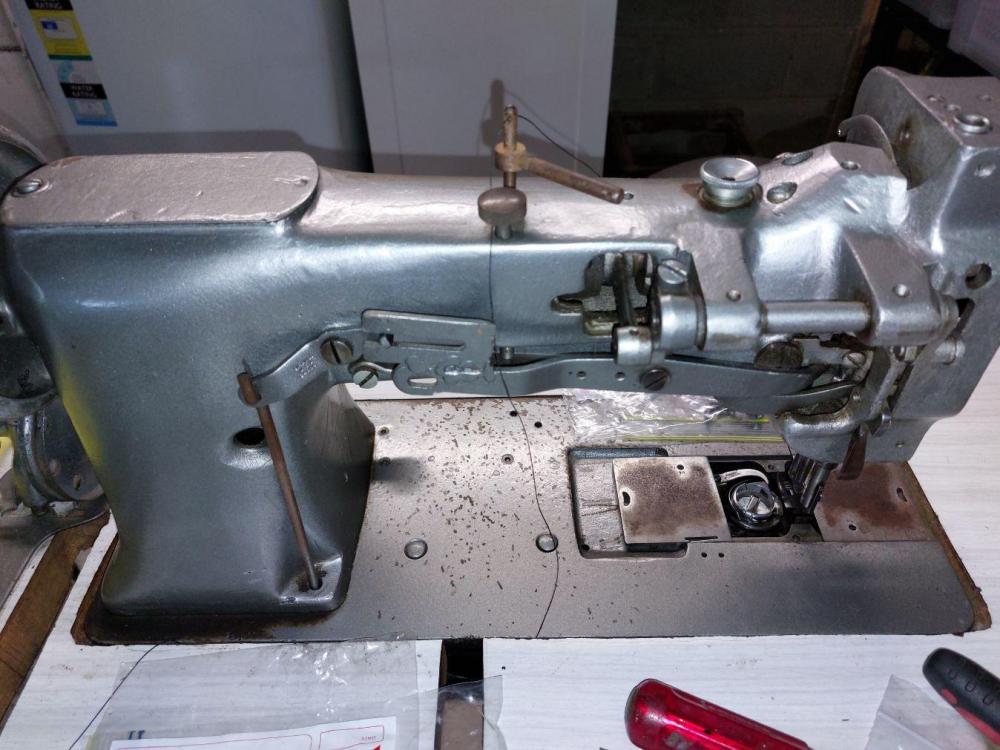

I just bought this Singer 111w113 machine from a guy in Ohio who said his son used it for years making Corvette covers. It was serviced within the last few years and apparently runs great. Well when loading it into my truck, the guy dropped it and it hit the ground hard. He assured me it was fine, but when I got home I discovered the extent of the damage. The flywheel had broken from how it landed during the fall. I've seen replacement flywheels online, but the problem I discovered was that I couldn't adjust the stitch count, and it seemed to be stuck in its highest setting. Upon further inspection, it looks like the shaft the flywheel sits on has bent and also the threaded part has cracked. I can't figure out what this piece is called, or how to find it. I've checked some online retailers and even PDFs of original instruction manuals, but I can't find how to get a replacement for this piece. I hope someone is able to identify what I cannot. Thanks in advance!

-

I'm working on my 111W153 and reading lots of resources. Somewhere on this forum someone mentioned that another adjustment went hand in hand with hook timing (can't remember what, offhand). I'm wondering if there's an order of operations or list of other adjustments to make when looking at hook timing on these 111 machines? My timing seems to be right on but I'm not entirely convinced something else doesn't need to be tweaked. Thanks

-

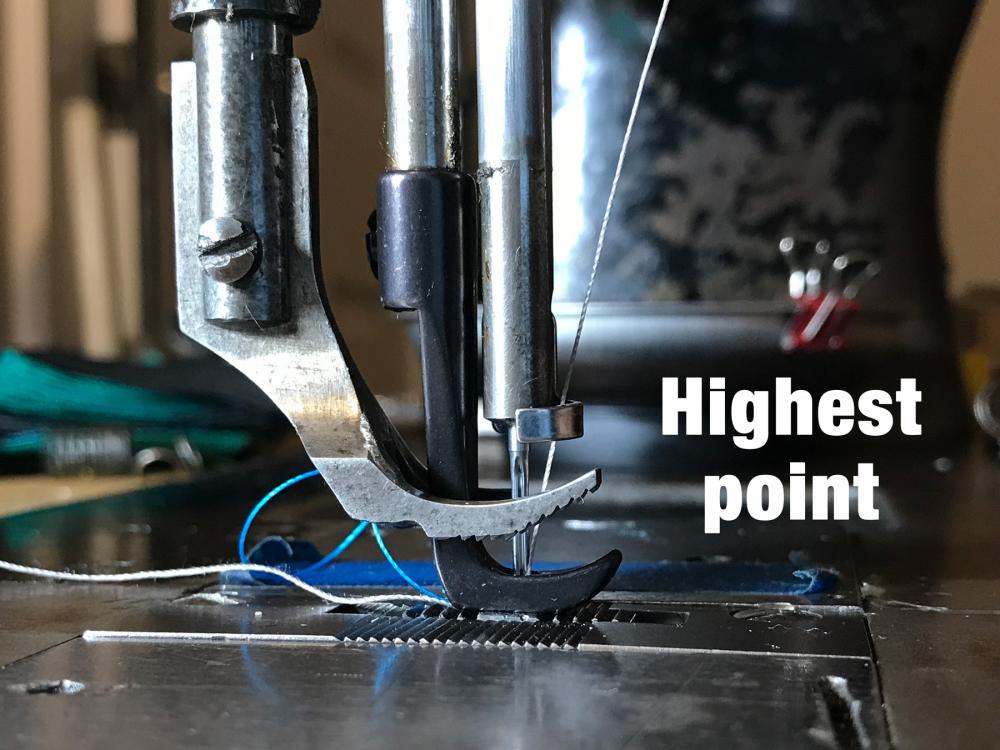

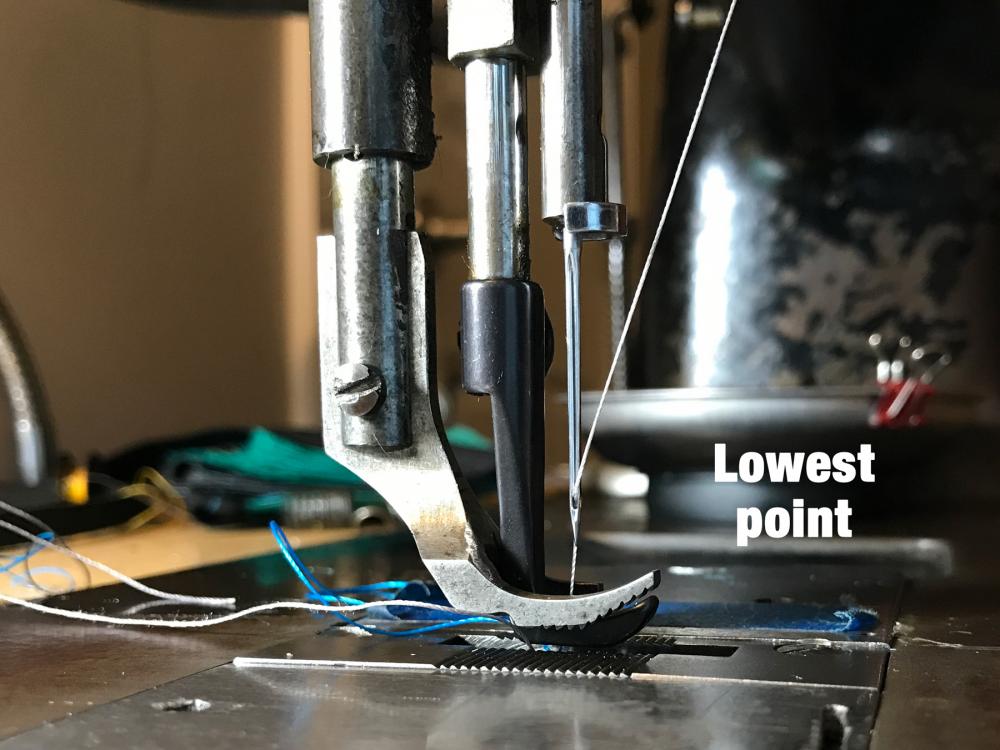

I bought a machine over here in Australia for my better half. I figured these machines are built well and parts are available, so just took the plunge. The timing belt had broken and the previous owners had sourced a new one they were supplying with the machine. The machine was looked over by a mechanic late last year so figured it was a safe buy. I removed the arm bushing (banged it up pretty bad removing it) and installed the new timing belt. I timed it with the take up lever and the arrows and then timed the hook, so she is capable of creating a stitch but there are a few things not right. The presser foot doesn't lift as part of the mechanism just sort of sits on the leather with constant pressure and the feed is out of time. I get the feeling a few things have been moved by the previous owner and trying to figure it all out leaves me feeling a few things are missing. From my studying, mostly from looking at the Consew 226 exploded parts list and the Singer 211 drawings and cross referencing with the 111G156 parts list, I think I am missing at least: 240500 - Tension release slide 240142 - Tension release slide spring 240185 - Vibrating presser bar extension 240188 - Vibrating presser bar spring 350299C - Vibrating presser bar thumb screw (pressure regulating) 200996C - Lifting bell crank cap screw Could the experts here and those with the same machine have a look over these photos and advise if these are required and any other missing parts I may not have picked up. Thanks Clive

-

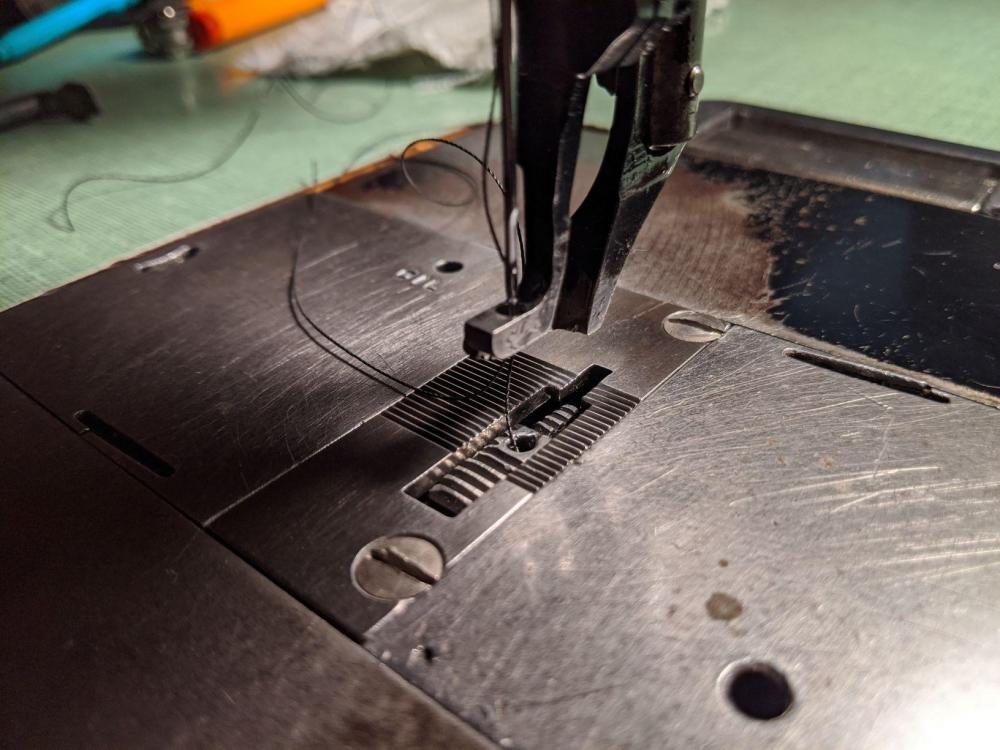

Hi All, I recently purchased a well used Singer 111W155 locally. Came with an old singer table, GE motor and Singer Clutch. I transplanted it into a more modern table. It was sewing fine but seemed to be skipping stitches. So i went shopping for new parts. So far i replaced the Timing belt (Was not broken but seemed about to), Hook (The basket was loose), New Tension Disk set, new bobbins, new needles. I cleaned it and lubricated it, Timed it and it is still skipping stitches. I tried everything... new needles, different thread different material and feed speed and still no luck. It seems to work fine for a while then every once in a while, it skips a stitch, sometimes 2 or 3 then goes back to normal. This can happen consistently on test pieces with about 3 inches of stitch so its pretty bad. The machine is quite worn and the feed dogs and throat plate seems worn also. The foot is a narrow foot set and also seems to be worn. I suspect what is happening is that the hook is able to get the loop most of the time but due to the slop in the foot or dogs or throat plate, the needle deflects and its just enough to miss that loop. I keep playing with the hook adjustment to get it close to the needle scarf and it seems every time i look at it, its in a different position (Either too far or touching the needle). I thought about the worst, too much wear in the needle bar bushings or even worst a bent needle bar but im really thinking it needs new feet, a new throat plate and feed dog. Before i drive myself crazy and spend more money on parts, can anyone think of what i missed? Thank you!!!! Andre

-

Hi All, I have just recently picked up a Singer 111w154 from and old trim shop that have got themselves an upgrade. After using this great forum to time the upper and lower shafts and then set the hook and needle timing it appears i'm unable to get less then 6/inch. I plan on using this machine for automotive upholstery and would be great to get 5/inch for when i french seam. The machines width selector does appear to work when increasing the stitch count but when it is set to 5/inch i only appear to get 6. Does anyone know the best way to adjust this from below the bed ? thanks in advance.

- 6 replies

-

- compound

- stitch lenth

-

(and 1 more)

Tagged with:

-

Just acquired this singer 111wsv31 looking to find out some history if anybody knows anything. All I can find is by SN# it's pre 1940'. The W is made in Bridgeport, CT and the SV is what some call "special variety" or custom made for customer. From what I can tell this is the predicessor to the 144w201. It's a 20" throat with no reverse. It seems that it takes quite a few normal 111w parts but obviously there's many that aren't. It sews beautifully and has some unique cast iron legs with the singer insignia casted onto them. Anything helps. Probably going to sell if anyone's interested. And I'm sure this being my first post to the site... I'm probably in the wrong spot. Thanks in advance

-

Just acquired this singer 111wsv31 looking to find out some history if anybody knows anything. All I can find is by SN# it's pre 1940'. The W is made in Bridgeport, CT and the SV is what some call "special variety" or custom made for customer. From what I can tell this is the predicessor to the 144w201. It's a 20" throat with no reverse. It seems that it takes quite a few normal 111w parts but obviously there's many that aren't. It sews beautifully and has some unique cast iron legs with the singer insignia casted onto them. Anything helps. Probably going to sell if anyone's interested. And I'm sure this being my first post to the site... I'm probably in the wrong spot. Thanks in advance https://photos.app.goo.gl/PNDNwHAKxe8sbBmM7

-

Hi Everyone, I know the 111W is really popular, but I'm wondering if there is a good comprehensive listing or history on the model variations that someone can point me to. I'm considering a Singer 111W113 that's quite a bit of distance away from me, and I'm wondering if it's worth picking up. Here are the listing photos: https://imgur.com/a/94YcVXW The only info I have so far is that it "runs well, and includes many spools of thread" since I've only just contacted the owner. Thanks in advance for any help.

-

I'm relatively new to the world of sewing and I've begun to get my Singer 111W113 back in working order after having it in storage for the past two years. When I bought the machine back in 2014 everything was aligned and the outer presser foot operated properly. While putting everything back together I'm realizing that the outer foot has far too much clearance, especially when sewing a few layers of material. I'm currently working with a lot of Cordura and heavy canvas for making bags. 6+ layers of Cordura are thick enough to make contact with the outer foot and provide pressure. Less material just slides around freely. I've made attempts to adjust the height of this bar but it seems to be in it's lowest possible position. Is there more to adjusting the outer foot pressure / clearance than just the screw on the top rear of the machine? Thanks in advance!

-

Hello, all. I've spent more than a few hours in the last few months lurking and dreaming, and finally lucked into two free blind stitch hemmers on Craigslist that I turned into a trade-in for a beautiful Singer 111WSV65 with new table and clutch motor. $100 on top of the trade and I was out the door from the fantastic Ralph's PowerSew in Denver...I think I scored, to say the least. My first industrial! I have a few month's experience with a crazy left-handed cylinder bed machine with no reverse making medical leather ankle-foot orthotics a few years ago, so I know I have a steep learning curve ahead of me, but I'm going to have fun with this one. For some reason, making a beautiful tooled leather clutch purse for my daughter to treasure and use as she gets older is my first dream project, but maybe a little upholstery repair is on the horizon, too. Staying handy for my employer with some canvas medical instrument covers in the next few weeks might be one of my first projects to rebuild my skills. I doubt I'll ever step up to holster thicknesses, but want to be ready for projects a little thicker than garment leather. Like I said, I've lurked, and now searched, but would love help with specific info and resources to get me up to speed on this machine, whether in this forum or elsewhere on the net: - history (I'm guessing this is a "special variance" machine from about WWII, but what does that really mean?) - capabilities (what thicknesses and thread, etc., can this machine handle?) - manual - service manual - parts / clone-parts - accessories - tips and tricks - modifications to consider Thanks for your help!

-

I have two walking foot industrial machines for sale. Singer 111w155 and 111w153, complete with industrial tables and motors. Both are in perfect working condition, timed, oiled and ready to go. Great for leather, denim, canvas, vinyl upholstery, and more. $600 each, or $1000 for both. I am located in New York, NY. Willing to discuss shipment options if local pickup is not possible. Text or call Jeff: 646-470-9445 https://www.youtube.com/watch?v=H-8c1LN6usA

-

Hi there, I'm in need of some help/advice on my Singer walking foot machine. It did work when I bought it, however it would jam pretty quickly. That's what got me started messing with it. Plus I like to learn how things work and I'm usually pretty good with fixing things. One issue is this is a first for me, so I have no reference point to work from. It could be a little messed up or really messed up and I wouldn't know. I was able to download many Singer instructions etc. But the images are always poor, and again they don't really start you from scratch. I'd like to be able to start at zero and check everything along the way so i don't mess something. That seems logical to me. I have a bunch of videos showing the problems I've had, some of which I did fix, but then something else would go out. The latest issue is that the feet are not working right, they feed the material back and forth not front to back. Also the stitch length is at the largest yet the stitches are tiny. Maybe b/c the feet aren't working right? Any help is appreciated. This is the link to my Youtube videos. https://youtu.be/hTd43J64xmc Alan

-

I just committed to buy an old Singer 111w105. I don't know much about them other than they're old, and they weigh about as much as a refrigerator. Has anyone had one? The foot looks like this in its current state. Any intel would be appreciated. This is a little side project I may live to regret!