Search the Community

Showing results for tags 'tree'.

-

While browsing Youtube for videos of English saddle construction, for some very strange reason this suggestion popped up. I speak very limited Spanish, so I can't make out what kind of straw that they use, and I think the saddle might be for the horse mounted person in a bullfight arena, but I am not sure. The interesting thing is that the saddle is built without a traditional tree. All the stiffness comes from straw. There is also some interesting decorations, that I guess are traditional. Definitely worth watching.

-

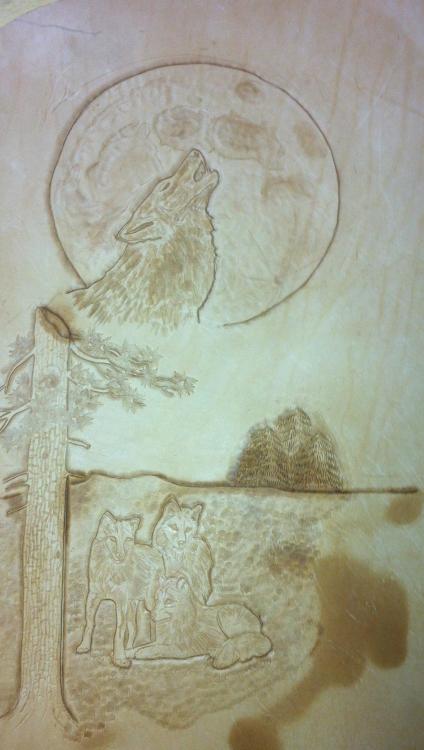

I did this for a girl who wanted me to make a gift for her boyfriend (now husband) for Christmas. I’ll just show the finished art without dyes. Each item was done individually and at separate times, when the picture was take it was still drying. Yes this is on 9/10 ounce leather!

-

Hi everyone, starting build for the first time. I'm going over the tree and there are some fairly craterey holes from the nails in the rawhide around the base of the forks and a few other places. I was going to start laying some leather strips in to smooth out the areas but I was wondering if I could put a filler in the deepest holes first. I feels a little sacrilegious to use bondo but I saw someone using it on here before. Also found plenty of proud nails in the seat I need to hammer down too. Thanks!

-

Hello, I was wondering if anybody out there has either a Wade or 3B Visalia tree they'd like to sell? I'm not making this custom for anyone but would like it to be all "average" sizing, no extremes on bars, seat, width, etc. Preferably between 15 - 16.5" finished seat. No production line or fiberglass trees. Not looking for cheap, just something I don't have to wait 2 - 4 months on. It's for a fall/winter projects to keep my mind off of my surgery that will keep me house and on crutches bound for a few months!! Thank you, Carol

- 3 replies

-

- wade

- saddle tree

-

(and 5 more)

Tagged with:

-

Hello All, Finished this saddle last weekend. It has just two coats of light oil. Specs are: 16" seat, Ben Swanke tree (4-1/4" x 90 w 5x12 cantle), Guadalajara horn, daisy stamp, 5" monels, in skirt rigged - Placed between 7/8ths and 3/4 position. Still lots of imperfections - Dented cantle sewing cantle binding - Awl snapped and I jabbed handle into dish...Also, the seat has a little too much rise to it by my eye. Wish I had of got about an extra 1/4" out up front... Look forward to any critiques folks might have - Always looking to improve my work. Thanks - Ron L

- 9 replies

-

- wade saddle

- inskirt

-

(and 2 more)

Tagged with:

-

I am starting my fourth saddle and I always try to lay out and mark some reference points on the tree such as boundaries for stirrup leathers, center lines on the horn and cantle, etc. Since there is no flat or square area on a saddle, does anyone have a better way than measuring/eyeballing/measuring/eyeballing until it looks right to mark reference points that are true? Any input would be appreciated. Thank you.

-

I have rustic forged chopper I made ( no pics right now) and wanted to do something freehand to kinda match. I know this isn't pretty, just looking for tips on where I can improve next time, and maybe make some alterations before I stain. I also understand tooling is difficult at this stage, but I kinda want to add a moon and clouds upper left but don't know how. Thanks Chris

-

I am looking to buy new or used poly trees made by Laporte saddle trees or Chicago stockyards. Especially those with a cable rigging. I mostly build on association trees but could use wades as well. I appreciate any inquiries. 970-946- six zero six zero

-

- poly tuff

- cable rigging

-

(and 3 more)

Tagged with:

-

I want to build my son a saddle. He's about 5 years old. I have experience building saddles. I've built about 12 now but only for adults. Just wondering what size of tree should I order how much leather I can expect to use a good tree style any other tips would be appreciated. Thanks.

-

I am just starting my first saddle project... Tree: Timberline Wade - 15.5" finished seat, 13" cantle, 1.5" dish, Horn 3" x 4.25" cap @ 1.25" tilt - Bars set-up for typical Canadian ranch horse... Leather - Herman Oak Hardware - Stainless Steel from Sheridan leather I have attached a pic of the tree - What I would like to know for starters: I am trying to achieve the look / feel of the saddles you see Buck Brannaman riding - Really like how his horns are set-up - Sloping top, lots of diameter. This tree - Seems like there is a lot of undercut under the front of the top cap, a little more than I hoped for...Would there be anything wrong with cutting and skiving a piece in that woudld wrap around the front face of the horn post only to build it out? Nailed and glued of course? Would this be a bad idea? Basically it would reduce the undercut by 1/4" or so... How much undercut will dissapear once I finish this - wrapped in leather and then wrapped in 'mulehide'? Also, have read that some don't finish their horn posts in leather - They just use donut cap and proceed to finish wiith the horn wrap? Any comments on this? I'm inclined to think I want my horn post finished in leather and then wrapped in mule hide... On a horn this size - Cap and wrap or donut & filler - How to finish post with donut & filler? Any advice and comments will be appreciated! Also, a bit of background - Fairly new to leather work - Have built several pairs of tooled chaps / chinks, built rear cinches etc. Have all of Al Atohlmans saddle making books as well as Harry Adams, However, going to be using Steve Brewers ground seat techniques as they seem like a better way to go... My goal is to build a plain, smooth out working saddle - Be nice to have it ready for branding season.

-

From the album: Various Book Covers