Search the Community

Showing results for tags 'vinegaroon'.

-

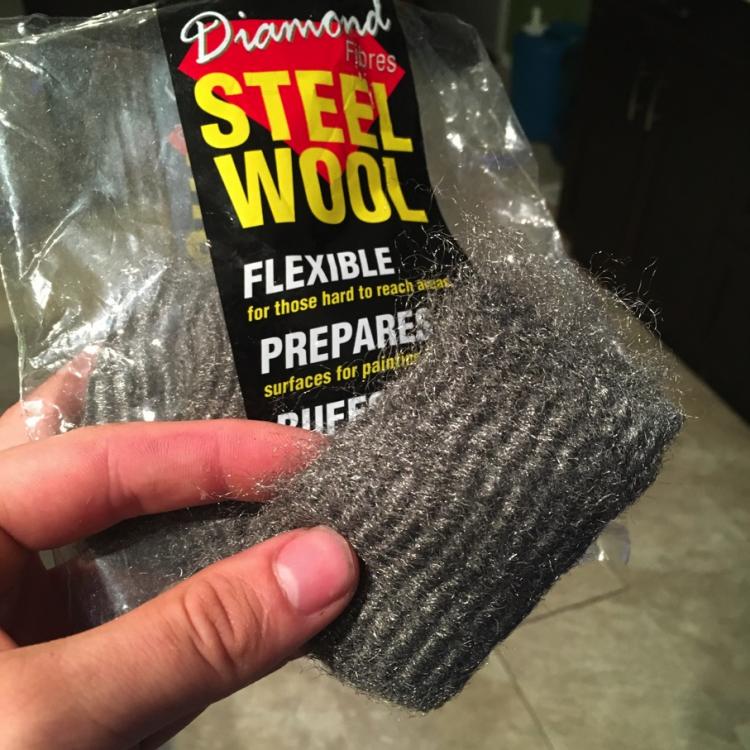

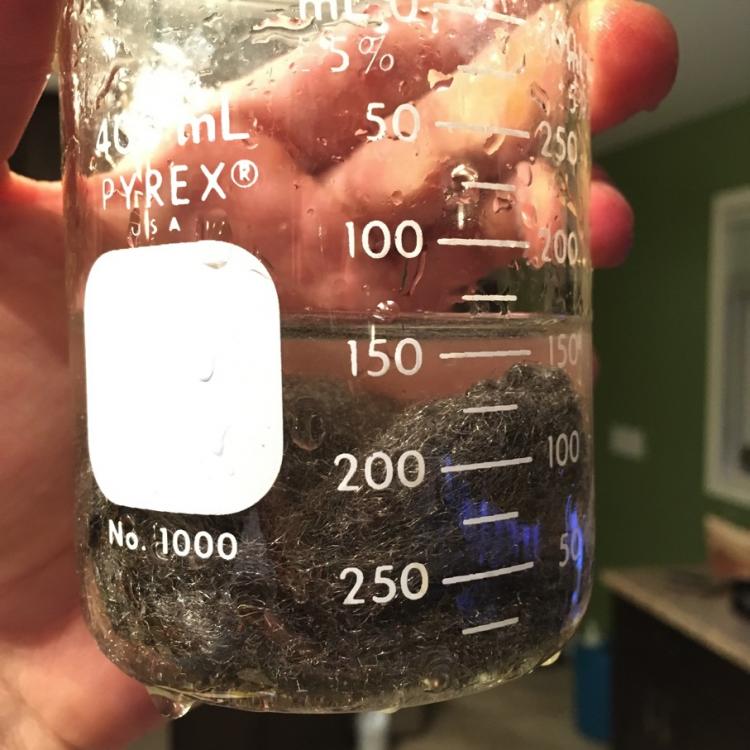

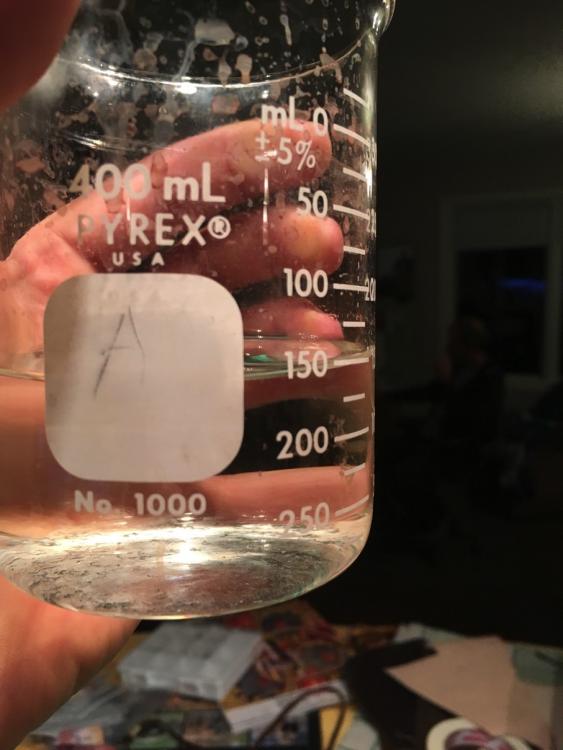

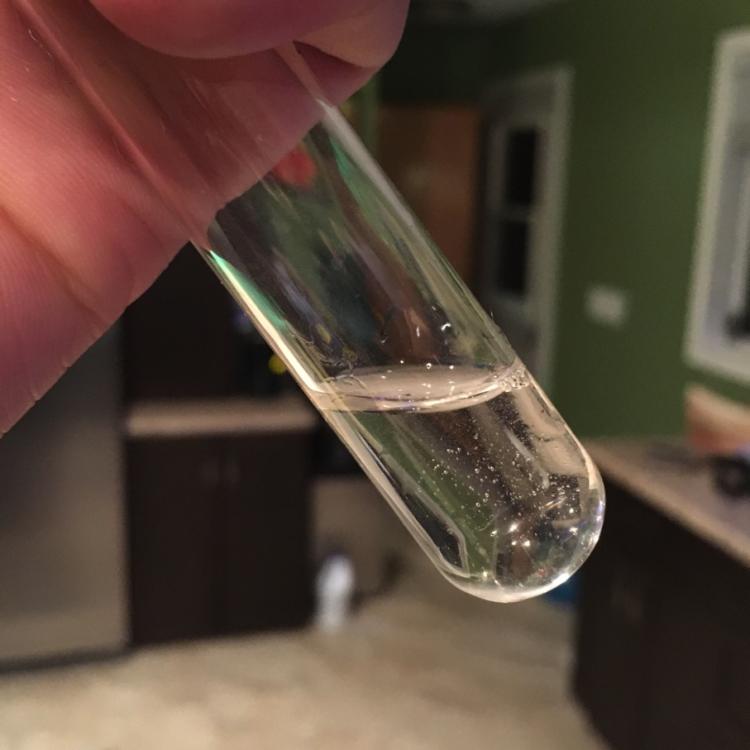

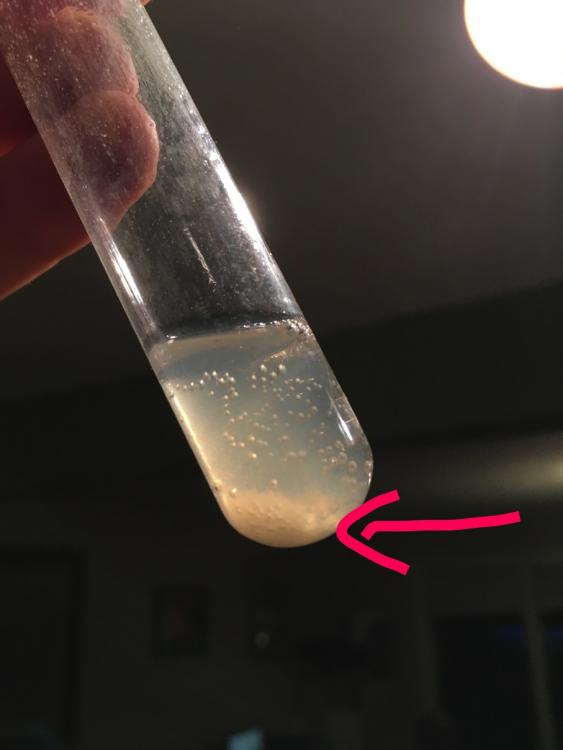

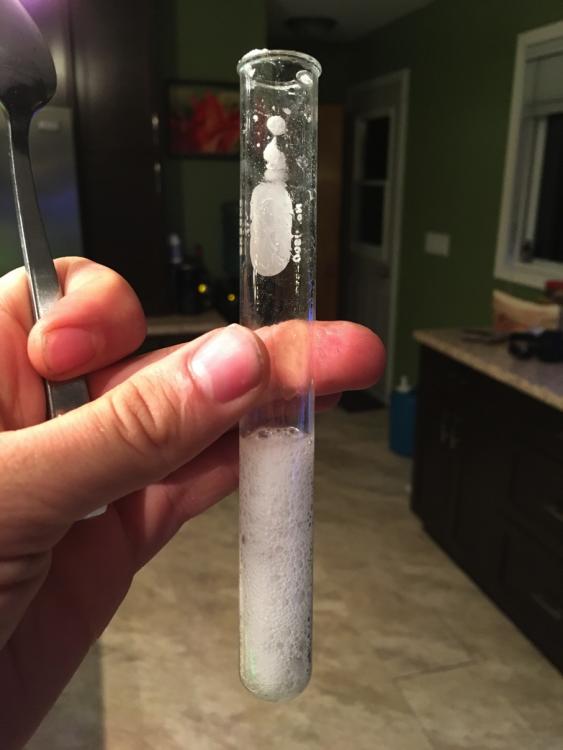

My all in one guide to Vinegaroon Hey everyone. I’ve been lurking around these forums for a while now and haven’t posted much, so I thought I’d finally make a contribution. I’m going to University for a Chemistry degree, and surprisingly some of the things I’ve been learning in my labs are actually applicable to my leatherwork! I thought I'd write up some of my observations and experiments with vinegarroon, to try and help shed some light on what is actually going on in the reaction. Please, read through and share any knowledge you have working with this stuff! (I know this is a lot. I was bored just typing it. You can skip to the bottom if you don't have time to read it all) Background Vinegaroon, or ‘roon, is a homemade black ‘dye’ that has been used by leatherworkers for centuries. It is also used by woodworkers to ‘ebonize’ wood, and was used since the 5th century as ink, called ‘iron gall ink’. It is not actually a dye, but a reaction between ferric acetate and the tannins that naturally occur in leather and wood. Tannins content varies between hardwoods and softwoods, and can be boosted by brewing a strong black tea and wiping it on the wood. I assume that this is also true of leathers. I have a few junky tandy's sides that are pale in appearance, and they seem to be low on tannins because roon has less of an effect on them. ‘Roon is used by many leather and wood workers but understood by few. It can be very useful alternative to commercial black dye in areas where dye is unavailable, too costly, or undesired because of environmental reasons. Also, because it is fundamentally different than other dyes, it will not bleed or crock (rub off) onto fabric. Pros: -easy to make with household materials -available in places where dye is not, or shipping is too expensive -nearly free -does not bleed or crock like other black dyes Cons: -often does not make a deep enough black colour without lots of neatsfoot oil added afterwards -can make your product smell like vinegar -acidic nature can cause issues with metal hardware in contact with the leather, might also degrade then leather after long periods of time Typical Recipe: (not recommended by me) Put some old rusty nails into a jar of vinegar and let it sit for a week, or a month. Filter it through cheesecloth and wipe it on your leather. This produces a nasty, smelly mixture of a whole bunch of iron complexes and compounds. The active ingredient, iron acetate, is in there, but along with a whole bunch of other junk you don’t need. It doesn’t have to be this way. With some chemistry and a little bit of research into the mechanism here, I’ve made a crystal clear, mostly odourless solution that only takes half a day to make. How I did it: I bought fine steel wool from the dollar store, which came in small bats. Any steel or iron will do, but fine steel wool has the greatest surface area so it will react the fastest. Metal shavings/powder would also work, but I’d think they would just clump on the bottom of the jar and prevent the vinegar from reaching the bottom layers. I washed one bat in soapy water to remove any oils left over from manufacturing. Some people have used acetone, which would work well, but seems a bit over the top when soap is cheaper. I pulled it apart and placed it in a beaker of regular vinegar, so that all the wool was submerged. You don’t need very much steel wool at all, even a quarter of the amount I used would be enough. The amount of metal actually being dissolved is in the order of milligrams or even micrograms. You probably shouldn’t keep a lid on it, because you are producing gas in the reaction. After a few hours, small bubbles form on the steel wool, causing it to rise to the top of the solution. I would mix it gently to dislodge the bubbles and keep it submerged. Every few hours I would use an eye dropper (so that I didn’t have to pour it out) to take a bit of the solution and test it on some leather. The darkening effect increased slowly over time until full strength was reached after about 12 hours. Still, I left the wool in there for 2 days to see if it got any stronger. Next time I won’t leave it in so long. After 2 days, I removed the wool. Since none of the wool was ever exposed to the air above, there was no rust in the beaker and I was left with a nice clear solution that didn’t smell much worse than straight vinegar. This is my vinegaroon solution. It turns leather black, is fairly stable, and is still acidic. The final product: a clear, nearly odourless solution of vinegaroon. Neutralization (optional): Next, I tried to neutralize the solution with baking soda to see if that changed the effectiveness of it at all. I took a small test tube of the ‘roon solution and put a spoon tip of baking soda in it. Obviously this will make it fizz up like your kid’s science fair volcanoe project, so I added it slowly. I didn’t have any pH paper to test the acidity so what I did was add an excess of baking soda (seen on the bottom of the tube), and then re-added the acidic ‘roon solution dropwise until there was no excess left. These images show the neutralization process, if pH paper is unavailable. A base (sodium bicarbonate/baking soda) is added in excess, which is seen in the bottom of the test tube by the red arrow. Then, the acidic vinegaroon solution is re-added slowly until this excess base disappears. The resulting solution is assumed to be neutral. This neutralized roon solution has the exact same reaction with the leather as the acidic solution. However, it was not as stable. After a hours sitting or a few minutes shaking, the solution turned into a cloudy grey-orange sludge. This is because the oxygen in the air oxidized the Fe2+ ions into Fe3+ ions, which are not soluble and have a rusty colour. Neutralized roon is good for immediate use, but turns nasty after a while What is happening? (skip this section if you don’t like chemistry) The iron is dissolved by the acetic acid and becomes a free-floating iron ion, in the +2 oxidation state, called Fe2+ or Iron(II). Hydrogen gas is produced in the dissolution process but in such small amounts that there is nothing to worry about. This ion is colourless and soluble in water, which is what we want. Furthermore, when this ion is in an acidic solution, like vinegar, it is relatively stable. Some of the ions complex with the acetate, which further increases its stability. When this mixture is applied to the leather, the iron ions interact with the tannins to form an iron-tannin complex, which is black. Oxygen messes with this system. Obviously there is oxygen in the atmosphere and dissolved in your solution, and this can oxidize the iron ions – it will take them from the 2+ state to the 3+ state. Fe3+ or iron(III) is NOT what we want, because it is orange and gross and not soluble in water. If this forms, it creates an orange/brown powdery solid that sinks to the bottom of the jar. To prevent the oxidation of the iron in solution, we need to keep the pH LOW and keep the oxygen out of the system as much as possible – by not pouring or shaking the solution. Now, the acidity of the solution is what keeps it stable – I’m assuming that you could store vinegaroon for a few weeks or months if you kept a lid on it. But the acidity is also what makes it dangerous for using with metal hardware. So what I’ve done is neutralized the solution with baking soda, just before applying it to the leather. The neutralized solution is just as effective, but noticeably less stable. The nice clear solution will turn orange overnight if untouched, or in seconds if shaken. So there you have it. Here’s a summary of what you SHOULD do: -keep the oxygen out of the system. Oxygen is your worst enemy, and turns this pure, clear solution of iron acetate into a sludgy, brown, stanky mess. -keep the solution acidic until you need to use it, then neutralize it if you need to before applying -use steel wool, as it has way more surface area than the same mass of solid iron And what you SHOULDN’T do: -don’t use rusty metal. It wouldn’t make a huge difference, it would just be introducing iron(III) into the solution which you don’t want. -don’t stir vigorously or pour the solution if possible -don’t use lots of metal, cause you only needs a little -don’t wait for a week, cause full strength is reached in less than a day -don’t put a lid on it until you’ve removed the iron, cause you’re building up gas in that jar -don’t worry about anything exploding either, there’s not that much gas -don’t filter it! Pouring it would introduce too much oxygen into the system. If you have stuff that you need to remove, it would be better to suck the ‘roon out with a turkey baster or something. What you could do differently than me: -using stronger vinegar, ie pickling vinegar, would speed up the reaction slightly and probably produce better results, since the pH would stay lower. Normal vinegar, however, is fine for most uses. -If you want to ensure that you have neutralized the solution, or gain a greater insight into the reaction process, pH paper would be very useful. -The solution could be neutralized with other bases, I only used baking soda because it was within an arms reach of the vinegar. Using sodium hydroxide, for example, wouldn’t cause it to bubble so much. -The solution can also be heated to speed the reaction, although I personally wouldn’t bother -Perhaps the best thing you could do is to calculate just how much iron will react with the vinegar and use slightly less than that amount of steel, to ensure that you have vinegar in excess. This will keep the pH from rising as vinegar is consumed by the reaction. This could be calculated stoichiometrically, or possibly by weighing accurately the mass of steel wool before and after to find out how much was consumed. I would assume that it wouldn’t be very much at all. Resources: The main reason why I found it so hard to find information on this reaction is because I initially had no idea what to search for. “vinegaroon” only can up with a few result, and most of them were not scientific explanations. I soon found out that it is more commonly used for “ebonizing wood” and that yielded a few more results. Finally I came across some scientific papers for Iron-acetate and iron-tannin complexes. Here are links to most of the pages I found helpful in my search: http://chemistry.stackexchange.com/questions/35351/iron-chemistry-acetates-for-ebonizing-wood http://chemistry.stackexchange.com/questions/5027/how-does-the-mordant-ferric-acetate-interact-with-tannins-when-ebonizing-wood https://en.wikipedia.org/wiki/Iron_gall_ink https://pubs.usgs.gov/wsp/1459d/report.pdf Thanks a lot for reading that, if you made it all the way through! Ask me any questions or share your experiences with roon below!

- 54 replies

-

- vinegaroon

- roon

- (and 10 more)

-

Hi everyone, I am commencing a few initial experiments with vinegaroon, and I wondered if anyone had any experience with a few ideas The darkening process of vinegaroon, as I understand it, is due to the reaction between iron (II and III) acetates and the tannic acid in vegtan leather. the role of vinegar is simply to dissolve the iron into a solution of ferric and ferrous acetate salts. If this is the case, it should be possible to pre-neutralize the vinegaroon using either baking soda or perhaps hydrogen peroxide (potential side formation of insoluble iron carbonate and iron hydroxide precipitates should be easily removed by filtering, and should not remove too much iron acetate before neutralizing the solution as long as most of the remaining acetic acid has already reacted with iron. A pH meter or universal indicator paper could be used to gradually titrate the solution towards neutral before using to dye leather This pre-neutralized vinegaroon should not overly acidify the already acidic leather, removing the need for a baking soda bath and avoiding the problems with potentially over alkalizing the leather. There is perhaps an increased potential for the solution to go mouldy over time (although the high concentration of iron salts should probably prevent this) but if this were a problem small amounts of vinegaroon could be neutralised before use, leaving the bulk solution acidic for storage until needed. As an initial experiment I pre-mixed a small amount of fresh vinegaroon (on the day I made it) with excess baking soda until the result was definitely alkaline (in fact the result was a paste with unreacted baking soda) and it still dyed the leather black. I have no doubt I over alkalized the leather in the process, but the point was to confirm that the acidic conditions of the vinegaroon are not necessary for the reaction with the tannins. I have a batch of vinegaroon maturing and have ordered a pH meter and some indicator paper, and plan to experiment properly in a few weeks, but am wondering if anyone has conducted similar experiments or can comment on my understanding of the chemistry. Also, if anyone has an idea of a potential base to neutralize the solution which won't precipitate out some of the iron ions, I would be interested. My hope is that pre-nautralised vinegaroon could be simply be rinsed off, leaving a dyed item that should not corrode metal hardware like snaps and rivets

- 5 replies

-

- neutralize

- vinegaroon

-

(and 5 more)

Tagged with:

-

My question is: Has anyone had any issues with the the more environmentally friendly tanning processes used today affecting the darkness of their vinegaroon reacting with their leather? Reason why I ask - see below. Yesterday I attempted to vinegaroon die a leather belt blank I had purchased from Tandy for a Dress Belt (Gift). I have not used, but had some old vinegaroon in the Garage in a seal container and still smelled of vinegar. Thank you, Vikefan

-

1st step is to make the rust. You need 30% food grade hydrogen peroxide. I used a 12 oz bottle added 2 oz white supermarket vinegar and 2 table spoons of salt swirled it around in a spray bottle until the salt dissolved. then hardware store steel wool, dunk it in a bowl of acetone, shake it off and separate/pull apart the wool so that is not all compressed and use a heat gun or hairdryer to dry it. You don't want it catch on fire. So low heat and then.. once dry spray the wool with vinegar and let it dry. U can use hairdryer again if you don't mind the smell. then spray with the hydrogen peroxide/vinegar/salt solution and INSTANT RUST. BE CAREFUL WHAT ELSE GETS SPRAYED WITH THE HYDROGEN PEROXIDE. things can catch fire apparently like organic matter. I did it in the garden and the plants didn't catch on fire but you can see a lot of heat is produced. Rust stains bricks etc. Let it dry out and then put it in a container with apple cider vinegar. I used normal and double strength and I can't tell the difference I don't think. The steel wool is dissolved much faster this way and your vinegaroon is ready pretty much straight away. Then of course you can apply it to your vege tan leather three or more times gets it pretty black. As black as you would ever want it. Dont forget to neutralize the vinegar with bi Carb soda and water. Just rinse with it. And then fresh water to finish. So it's not click your fingers quick, but it's not going to take days or weeks and making the instant rust is great fun. Any questions just let me know. Thanks

-

- best

- vinegaroon

-

(and 1 more)

Tagged with:

-

Here's a set of firsts: 1st time using the laser to engrave a design 1st time using vinegaroon to dye the leather black. I did end up going over part of it with oil based dye. I've still got some experimenting to do with the laser, the 2nd cut of the same design was better - but I've still to finish that one off.

- 13 replies

-

Hi, I have some vinegaroon that is about a year old. Its been stored in a mason jar. I tried a tester piece of leather and it worked fine and blackened the leather fairly quickly(2 minutes). I neutralized and applied neatsfoot oil while it was still damp. How long have you stored your vinegaroon. I have read a few stories on here about vinegaroon dyed pieces fading over time. I was wondering if anyone has ever applied a spirit black dye over vinegaroon. I would think it might add a deeper black to the occasional issue of the vinegaroon being a dark gray sometimes. I am guessing once the vinegaroon piece has been neutralized it should be ok to dye for the extra insurance that the piece stays a nice deep black? Thanks for any input!!

-

Hello all, I'm making my second batch of vinegaroon and I can't remember if I used Apple Cider Vinegar or White Vinegar the first time around. I also don't remember what size of bottle I got, and the ratio of wool to vinegar. I bought a gallon of apple cider vinegar. Will this work? Would white vinegar work better? How many pads of steel wool for 1 gallon? Thanks again, Zayne

-

I am puzzled. 8 months ago I made a shoulder holster for a friend. I used vinegaroon to color the leather. I followed Chuck Burrows' instructions for making and using the vinegaroon. When I finished it the holster was a deep true black. I made the vinegaroon using degreased steel wool, 2 large pads to 1 gallon of vinegar. After about a month I strained it well. All the steel wool had dissolved by 2 weeks time. When I used it on the leather I dipped the leather, let it set a few minutes then neutralized in baking soda water then rinsed well in clear warer. I let it dry 24 hours and it came out a deep grey color after drying. I used a small amount of olive oil rubbed in and wiped off then 2 coats of Mop and Glo diluted 50/50 with water. I air dried the holster between finish coats. After that was dried well and edges were burnished, I buffed in a very light application of soft bees wax. The leather I used was Herman Oak. I saw the holster the other day and the whole rig is now a very very dark brown. At night or in not very bright light it looks black, but in bright daylight it is dark dark brown. It seems to have faded. It is not exposed to the sun when used or stored, and is rarely used. Does anyone have an idea what might have happened and how to prevent this in the future? My friend is keeping the holster as he likes it, regardless of the color, but I am not happy that the color has faded. This was my very first adventure into making and using vinegaroon and I am disappointed andI had hoped to use it for all my "black dye" projects. Does anyone have an idea what went wrong? Any help would be greatly appreciated. Many thanks, Viking Queen P.S. I tried to take a picture of the color change, but of course it shows up black in the pictures.

-

I have been practicing with my swivel knife and stamps, that I inherited from my grandparents, on some old veg tan scraps from the Local surplus store, for about six weeks now and feel like I will be ready for my first projects soon. I want to make leather stick barrettes for my mom and me. I still need some more practice because I'm still not confident in my abilities yet, but I think I have almost everything I need. I'm going to buy a piece of belly from the surplus store to practice on since it's probably a little better quality than the supper thick, warped, dry scraps I've been practicing on. I ordered an 8-1/2"X11" 6-7oz piece of leather from Springfield LC. It was a nice piece, I liked the stiffness, but seemed a bit thin for the project, so I ordered a piece of 7-8oz and it should be here in a week or two. Should the 7-8oz piece be ok? for the stick, I'm using a dowel rod from Walmart, because that is what I use for my Native Amercan beaded stick barrettes. I want my barrette to be black. I'm brewing up a batch of vinegaroon right now. I've done a lot of reading about it here on the site. If it goes wrong, I have a bottle of black Feibings oil dye. Do I burnish the edges before or after I dye, or is it personal preference? I'm going to be burnishing with water, a wooden burnishing tool and paraffin wax. something I'm really concerned about is the finish. Mom wants the natural look and mine will be black. Since the leather we will use will be some what flexible, I'm concerned that acrylic finishes will crackle. Unless I could wet form them into the shape we want, but I don't know how that is done.We need a finish that is moisture resistant because we plan on wearing our barrettes almost every day, which means we might have damp hair when we put our hair up. I have read on the site that a 50/50 mixture of beeswax and neetsfoot oil applied to the leather, then melted in with a hair dryer was a good way to water proof leather. Would that work for this project? Would burnishing the flesh side aid in making it water resistant? On a side note, from what I understand, vinegaroon will turn some wood black. I think I'm going to cut a piece of the dowel rod off and see if it reacts to the vinegaroon. I'd like to have a black stick to go with my black barrette. If that doesn't work, some of the oil dye will work on the dowel rod, won't it? Thank you for your time.

- 2 replies

-

- water resistant

- dye

-

(and 7 more)

Tagged with:

-

Below is a pic of the first belt I ever made, maybe four years back. I used some real nice homemade 'roon but managed to burn it with the baking soda which as you can see made it very brittle. Basically I just soaked the belt in the soda until it stopped bubbling. Sometime after the belt was done I figured out that this wasn't the way but kept the belt anyway just to see what happened and when. Well, the 'experiment' is over. The belt got a small tear close to the buckle and I decided to try and rip it apart. Didn't take much, was like tearing off a stamp. At the hole there wasn't even a tear but I just managed to rip it anyway. Note that I oiled it with neatsfoot oil while making it but haven't oiled it since, it might have prolonged the lifetime a bit if I did. I have since made a bunch of other stuff with vinegaroon that's worked out fine, but for me the quite inconsistent results (using Tandy leather) has made me turn to other products and more recently I've started buying pre-dyed leather instead. Vinegaroon has it's place though (especially for period pieces) and if you use it -go easy on the soda.

-

Hey all, I have been searching for a tried and true method of neutralizing vinegaroon, and most methods I have found seem to be kind of vague, leaving me with a couple of questions: What is the ratio of baking soda to water? Does water temp matter at this stage? How long to dip/leave the leather in the baking soda/water mixture (all I have read is "not too long". I have no idea what that means)? I read that you need to oil the leather after you have bathed the vinegaroon dipped leather in the baking soda/water mixture, and then washed with warm, clean water in order to "bring life" back into the leather. I seem to have read (I think on cascity) that better results might have been had when applying oil before the leather had completely dried. Does anyone have any experience with this? Also, I have made a black walnut dye, and the leather still has a strange smell after dried, would neutralizing using the same method be beneficial? Thank you for any input! Zayne

- 18 replies

-

- neutralize

- neutralizing

-

(and 8 more)

Tagged with:

-

I'm getting ready to try vinegaroon for the first time on a project, so I made up a batch and tested it on a scrap of leather, brushing it on some of the scrap, waiting a day, and then soaking the leather in baking soda dissolved in water for a few (less than 3) minutes. I only vinegarooned the very end of the scrap, but I dunked the whole scrap into the baking soda solution. The vinegarooned portion came out perfect, and all vinegar smell was gone. However, the un-vinegarooned end of the leather seems to have been significantly darkened by the baking soda solution; it's now a medium to dark brown. My baking soda solution was about 2 tbsp dissolved in about 8-10 ounces of water. So, I have two questions: 1. Can a baking soda solution be used as a cheap dark brown dye, similar to the way vinegaroon is used for black? 2. I'm assuming the darkening of the leather is a result of the baking soda burning it, which presumably could lead to problems similar to not neutralizing vinegaroon. So, is it necessary to use a specific strength formulation of baking soda solution to prevent a swing from one end of the ph scale to the other, rather than ending up in the middle?

-

Hi, This is my first leatherwork, a collar for my dog. Leather strap is 3mm thick veg tanned leather dyed with vinegaroon, lining is sheep leather 1,2mm thick, veg tanned and already dyed fawn when bought. It is handstitched. I'm aware to advices and critique.

-

Hi Everybody ! I stumbled across Leatherworker.net completely by accident - due to the vinegaroon recipe. I have a couple of decades experience sewing garment leather on industrial machines, and some familiarity with working with belt leathers. I loved the idea of a permanent black dye, caused by a chemical reaction. I am making some placemats as a gift, and a permanent, non- transferable dye sounds much better than the stinky and not 100% fast Fiebings oil dye that I am familiar with. So - of course I ran right out for some vinegar, steel wool and acetone. This is what I did: I poured a bunch of acetone in a plastic tub. I unravelled the extra fine steel wool and dunked it completely into the acetone and squeezed it out (while wearing nitrile gloves). I let this dry overnight. I then put this into a plastic container (old gallon vinegar jug), and poured vinegar to cover. I left an opening for air. It is in a warmish place (68 - 72 degree F). I have been shaking it everyday - but so far (four days later) the liquid is only slightly greyish. For good measure I added some rusty nails last night. The steel wool looks only a tad rusty at the top. I read over many instructions and comments here and other places online. There seemed to be some differences of opinion about whether the steel used should be rusty or not rusty. Many people said they let it develop in a warm place in direct sunlight. Some people said they boiled it. Does it sound like my vinegaroon is developing naturally ? Did my steel wool not get de-greased properly ? Any input would be appreciated.

-

I have a very nice, but old, Passier english saddle that is brown (Passier uses exclusively vegetable tanned leather for their products). I'm thinking about using vinegaroon to blacken the saddle and had a few questions (total newbie). 1. Passier states that don't use any artificial finish. Now since this isn't a dye, do I still need to strip/use a deglazer for the oil in the leather from past conditionings? 2. Would it be ok to "paint on" the baking soda/water mix since I won't be able to literally soak the saddle (size and it has wool flocking)? 3. How long does the color typically last (on the saddle)?

-

Hi, Abosolute newbie at this, I know there is already a thread about a Coach bag but I have more questions. . . I have an old coach bag, originally bone coloured, that I dyed with Fiebings. after a good scrub with Acetone. Terrible rub off even though I buffed it for about 4 hours, especially the back, where it touches my side, Then - whoo who - I found this site and am begging for your help. I have scrubbed it down with extra fine steel wool and acetone to remove most of the dye and now want to try Vinegaroon. I have washed the bag (in the washing machine) and soaked it in black tea for about 5 minutes. It is hanging to dry as I write. What now? My Vinegaroon is only about 3 days old but it is the colour shown in the pictures and tutorials. and it doesn't really smell vinegarry I gallon of white vinegar and about 6 steel wool pads. Cooked, Cooled. Strained. Cooked again. Some questions: How long before I can use it? Does the purse have to be wet before I put it on? Do I immerse it or paint it on? How long do I let it sit? How long in the baking soda bath? How much baking soda is too much? Can I finish it with clear shoe polish? If not, what is recommended to finish it. I really like this bag and want to do a good job so any hints, warnings, how to's well, anything really, will be of great help, Thanks in advance Megan

-

My first batch of vinegaroon is finally ready and I had some quick questions. I have a saddle that I'm planning on using it on (I have seen it used on some old western saddles that were starting to look a little ragged). The leather on this saddle is vegetable tanned leather and well conditioned/oiled, and was originally dyed deep havana brown. My questions are: 1) Will it be possible to use the vinegaroon solution on previously dyed leather? 2) Is there any prep work (other than a tannin/black tea bath) that I will need to do to ensure that I get the best results possible (alcohol, deglazer ...etc)? Thank you!

-

I recently used some 4 year old vinegaroon on veg tan leather and it did not produce the same rich black that it did 4 years ago. I am not sure if this is because of some difference in the leather or because the vinegaroon is too old. So does anyone know if old vinegaroon produces less black color than new vinegaroon?