All Activity

- Yesterday

-

Hello, I am trying to locate an expert with leather that could possibly repurpose my father's leather jackets into other goods. My father passed away in 2020, and I have kept some of his clothing, but I am hoping to transform these into goods I use daily as a reminder of him instead of keeping them stored. Please contact me if you are able to do this or know anyone that could. I would greatly appreciate your help! my email: anaavazqueez@gmail.com

-

JG Made joined the community

-

A three hour drive for a $400 Adler? https://www.facebook.com/marketplace/item/2054185345347351/?ref=search&referral_code=null&referral_story_type=post&tracking=browse_serp%3Abe10a7d6-6af3-41d8-8614-d6d40fc79993

-

Not even close. The machine appears to have been repainted with the name tag also painted over. From the factory i) setup for binding ii) factory needle system was 134-35 LR iii) Max size of needle is a metric 100 (#16) iv) Max thread size is metric 40 (V69) Value: Unknown. If it was used in a commercial environment it may need unknown repairs so it would be wise to have someone check the machine over before purchasing. How much are they asking??? Most importantly what do you want / need to sew????? kgg

-

im an old pro. ive had a upholstery shop for 15 years. back then i bought a new durkopp adler 267. i used that machine without issues all that time. but i was moving and sold my house and workshop. then the sellers of the new place upped the price with 50k so i had to shift my focus to storage. my house and workshop is packed in 4 20ft containers and i have a old farm shed storage hall. as im looking for a new place. 4 months in and bored waiting to find my new place. i thought lets buy a little machine and do a little work. small budget as im paying rent and storage fee,s this one was suposed to be working just needed a little maintenance from sitting a few years. sadly i was mistaken XD so i just wanna get it running and make little projects i can sell again. i cant unpack the storage containers so i have been buying little things here and there to set up a temporary workshop. i have black red and orange thread at the moment so i can do 2 color. ill get to it tommorow again hopefully

-

ah thanks ill print it out and take it with me to my workshop and fight these issues. and see how far i get

-

What sewing machine should I purchase?

mwcondit replied to J Kellar's topic in Leather Sewing Machines

do some youtube research. look at the Juki 562 and 563. then watch some Cobra 26 videos. you want what I call a triple feed walking foot machine. that's way I say watch the videos on the Juki 563. It will do what you are asking for now. I think the 207 thread is too big. you should be able to use 138. which looks good on belts. the wallet ?? -

I love my Cobra 18. It puts down a beautiful stitch and never lets me down. I use 138 thread.

-

similar to the Cobra 26 or the Juki 341.

-

champagneboy joined the community

-

Can a worn case/hook prevent adjustment of case opener lever.

AlZilla replied to beefy's topic in Leather Sewing Machines

Funny, I didn't really look at it other than the height of the hook and opener. It's been running a couple of years now. Maybe mine needs adjusting, too. -

Scam Sewing Machine Give Away

nstarleather replied to JeffAmrhein's topic in Leather Sewing Machines

So just bumping it because I got a very similar email today...and it was familiar because I got another a few years ago. The one from the day I'm asking where there's from and wherever they're from "I have a friend there who can pick it up" and see where it goes. Bottom line, nobody is giving away a free machine and if they are they're going to go local first before going to the trouble of shipping and asking you to pay for it. -

nomadicworskshop joined the community

-

Can a worn case/hook prevent adjustment of case opener lever.

beefy replied to beefy's topic in Leather Sewing Machines

Thanks AIZilla. Looks like your case opener arm is not adjusted correctly, as it does not even contact the triangular outcrop on the case to pull the case anti-clockwise and open the latch on the rear/far side. It appears the thread itself is simply pulling on the tab of the case and thus forcefully pulling it anti-clockwise then the thread goes through the latch. -

Can a worn case/hook prevent adjustment of case opener lever.

friquant replied to beefy's topic in Leather Sewing Machines

Wow, lots of travel! And seems to achieve it furthest reach earlier in the rotation of the hook than the OP machine -

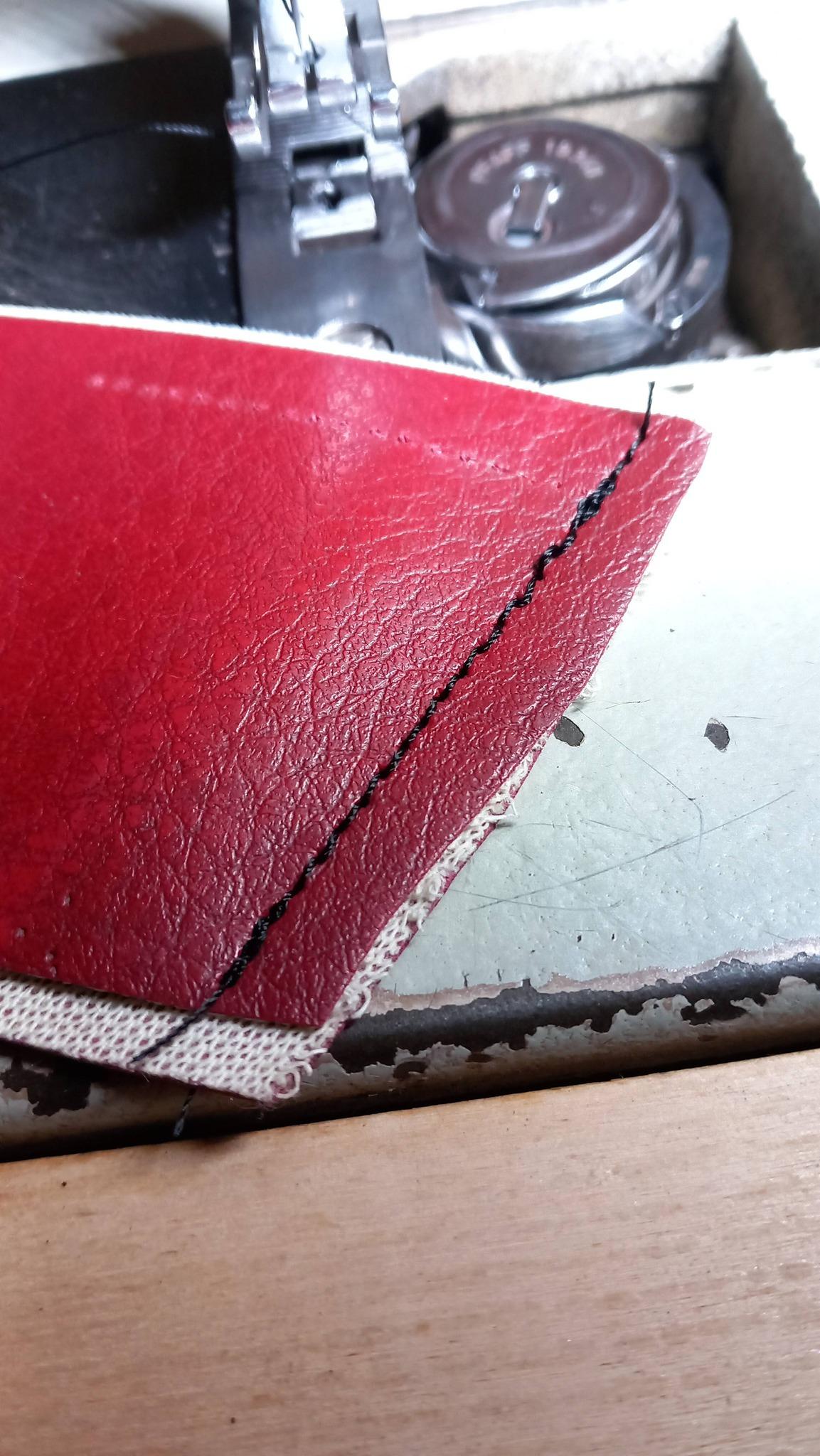

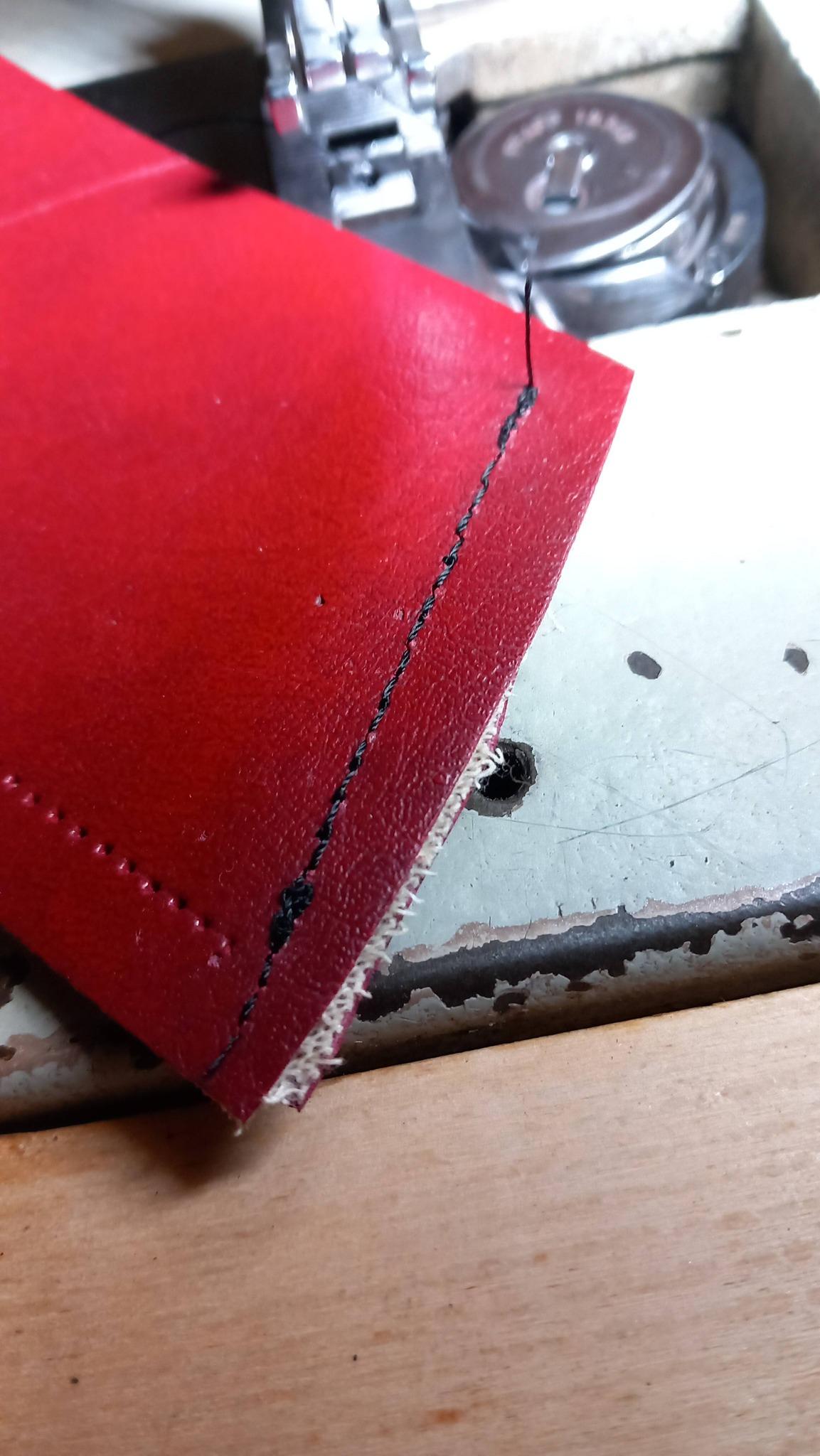

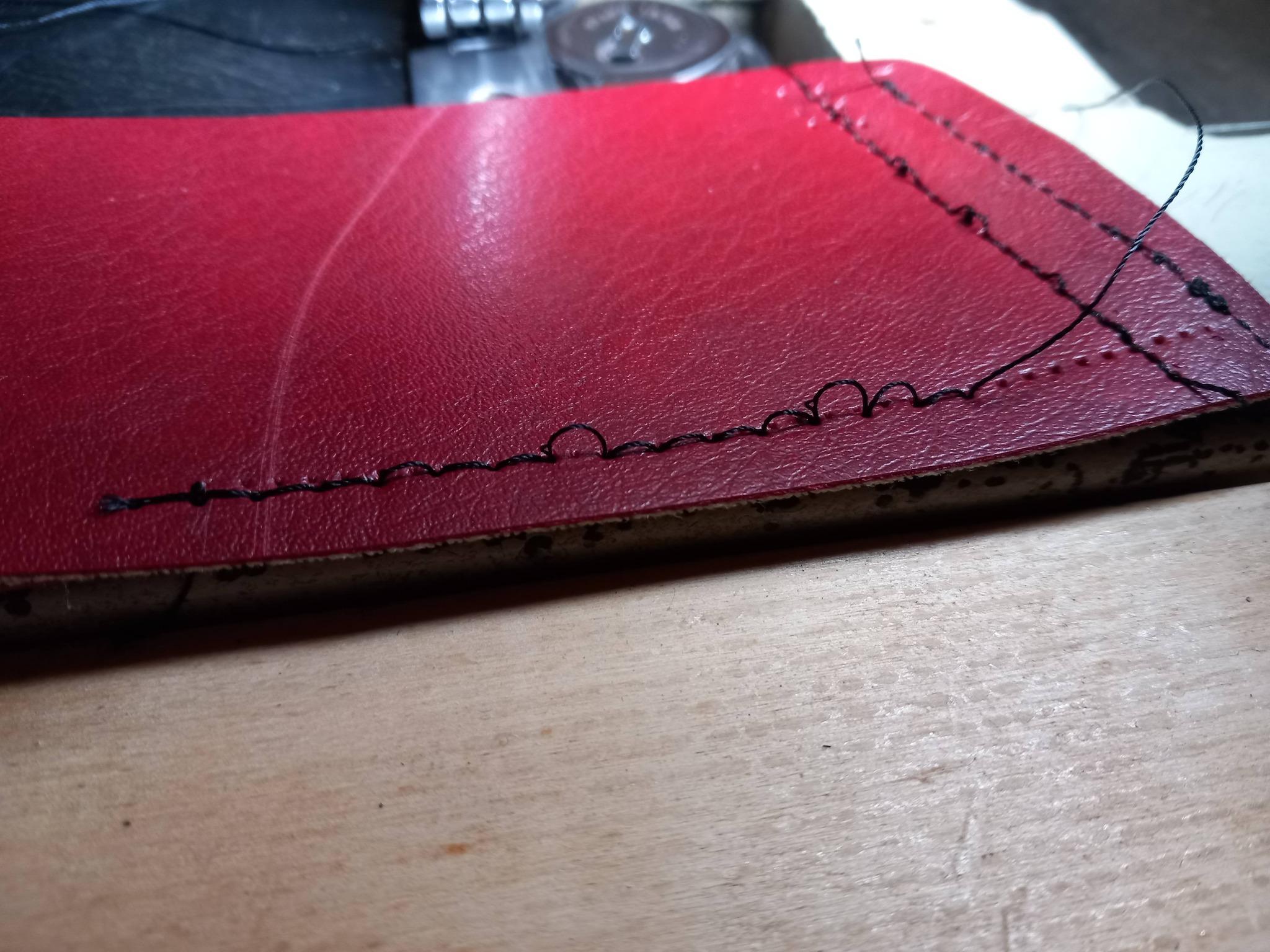

I see tension issues. You mentioned an upholstery shop, so I'm not sure if you are new to sewing or an old pro. Have you experimented with different tension settings to get the looped threads under control? For photos, do you have some white thread you could use for the needle thread so we can easily see which is top vs bottom?

-

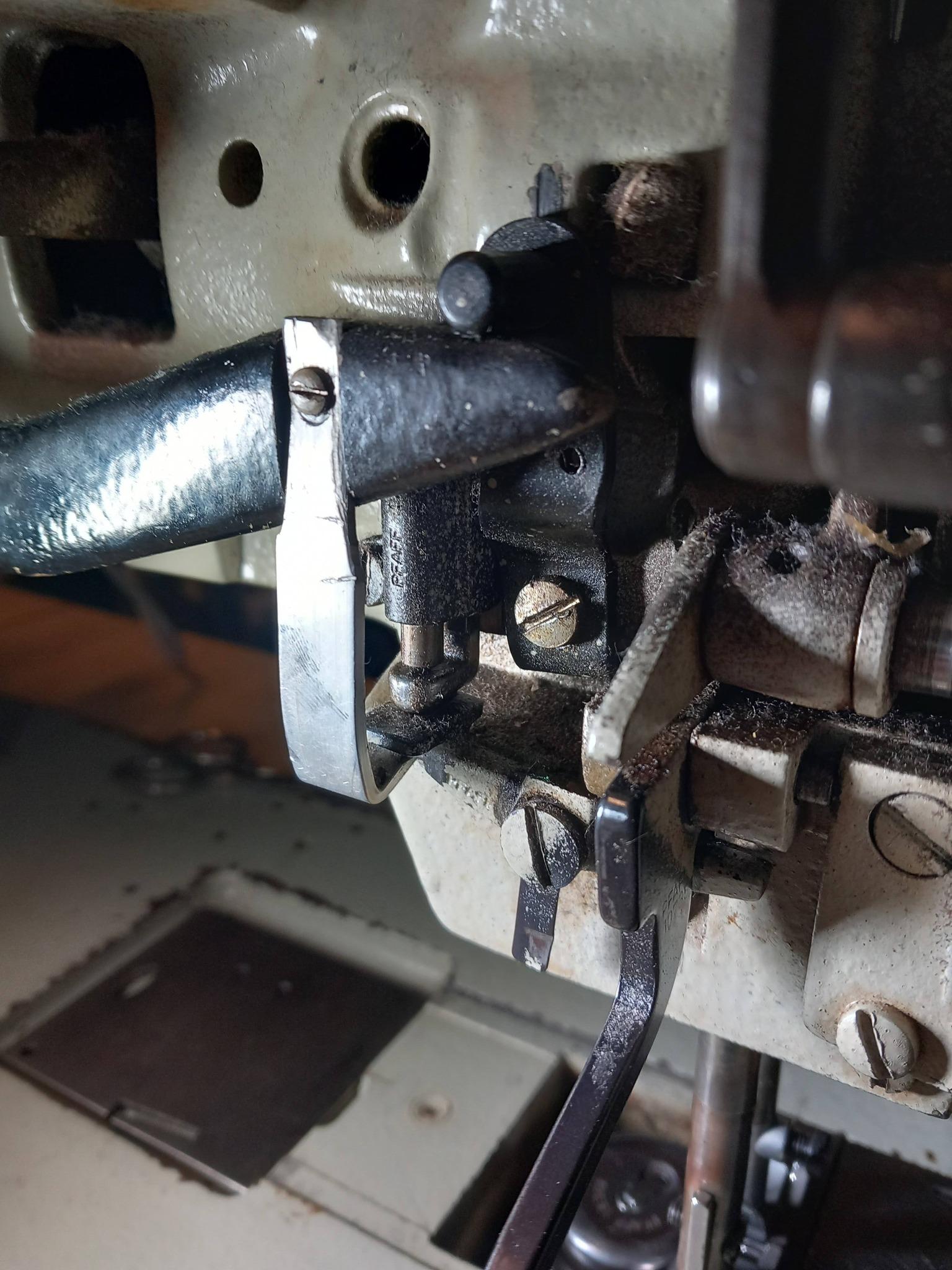

You have skipped stiches and a nest bellow? Have you checked the timing of the machine? here is one document, check the added text at the end https://docs.uwe.net/Pfaff-145-545.pdf you can also check different pfaff 1245 Service manuals which have nice graphics. It is much newer machine but certain things are same / similar etc

-

the good news is. i finally got it stitching the bad news is that it inst pretty or good. keeping the smallest stitch length its stitching just not good looking. but when i turn it up for longer stitches it starts messing up badly. so what does everybody think ? is it a tension problem ? any advice would be apreciated. i took apart all the stuff inder the needle i sanded down rough edges and cleaned everything. but didnt find any burrs or nothing. the under side of the feeddog had some carving that was weird in my opinion and everythime i used the knee lifter i heard a click and i found the problem. the bracket that helps take the tension of the top tread when lifting the feet was broken and the home made a piece that slips off and dont do much. so ill go look for a replacement for that. already spend 3 days working on this and i was ready to give up and bring it to a mechanic. but i learned they are hard to find. and the ones i called dont do it anymore only domestic machines. so that sucked. i need this machine to run and work for me. cant keep fiddling for ever on this. and dont have the money to buy another one and find that that has problems to XD

-

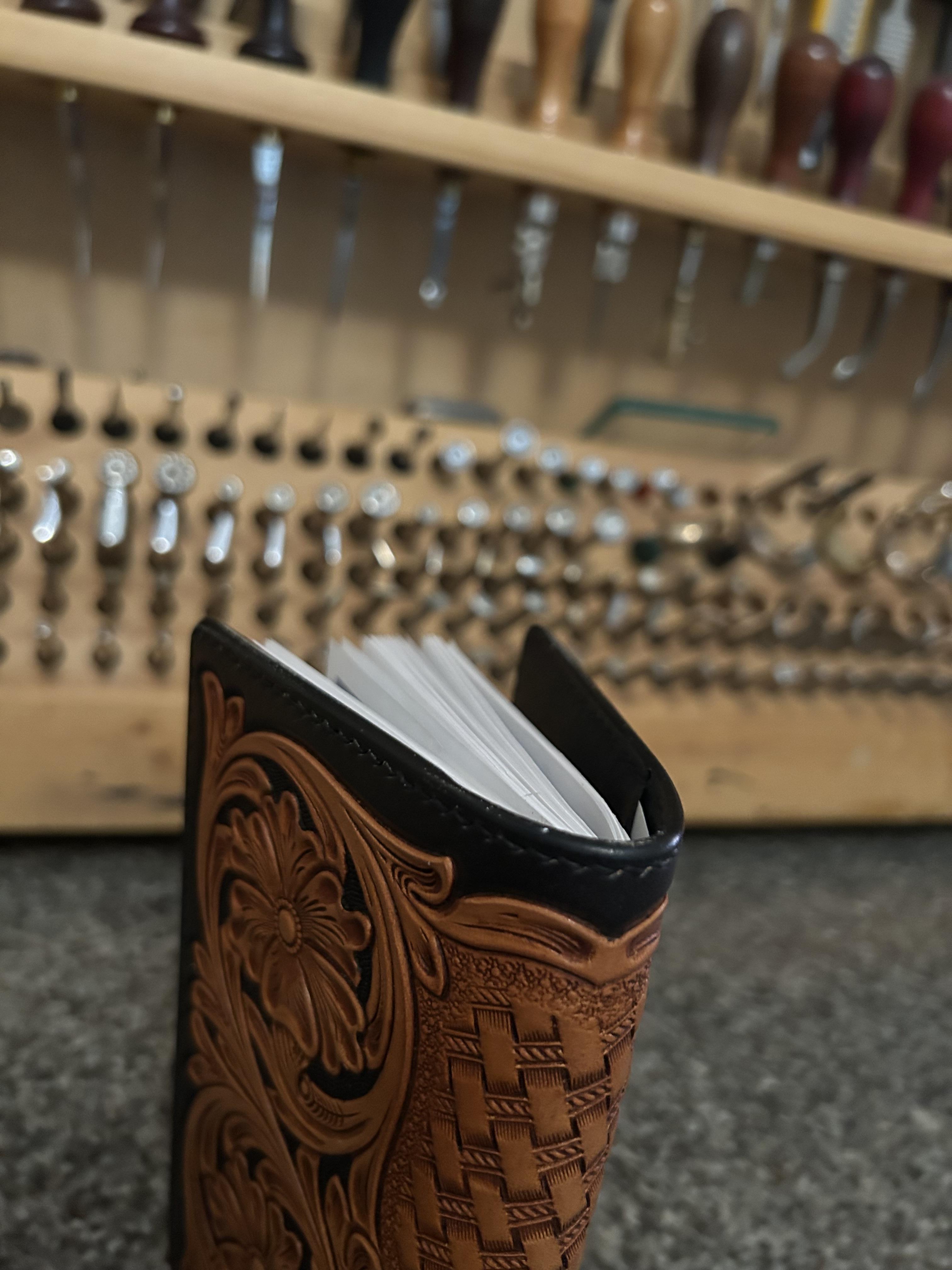

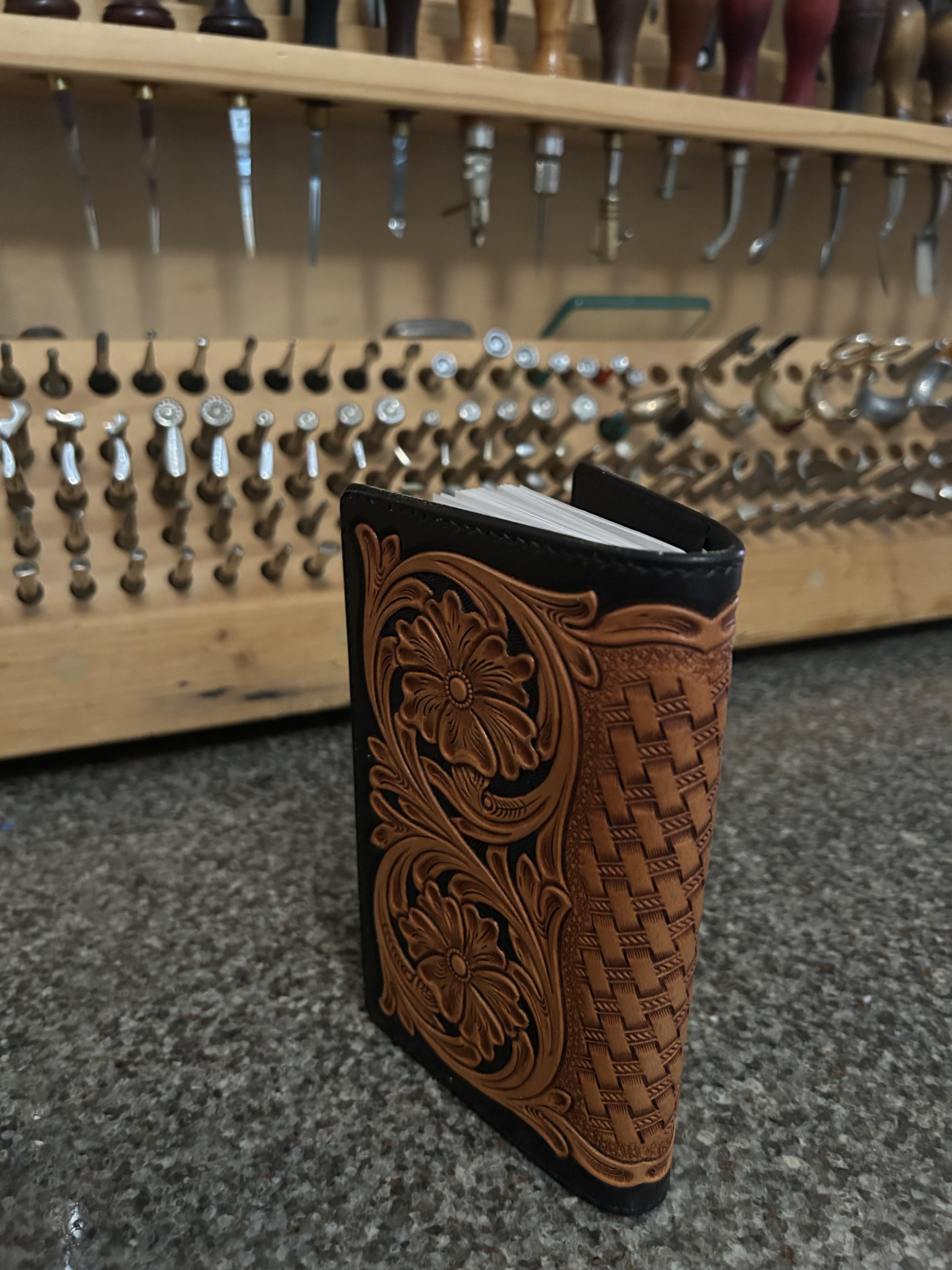

We’ve been iced in since Saturday so decided to practice a little. Made this cover for my daily planner. 3/4 oz Hermann Oak with a pig skin liner. It’s just dyed black and Sheridan Brown antique finish over natural leather, no resist. I haven’t put a topcoat yet. Want something I’ll be able to clean and oil later. I usually Wyosheen everything and I don’t like the way water base finishes look. Oil just seems to sit on top of the Wyosheen. Any recommendations.

-

I had thought about a Consew but went with a Kenidyne, a bit pricier but a fantastic servo motor - it will go down to 50 rpm, probably the best and most helpful thing I've bought besides my machine. And I do not get anything by mentioning them. Finding info is a bit time consuming but it's out there, look for cowboysew and hightex - and no problems with running the needle positioner once you program the controller to use it. The motor doesn't care if there is one or not, it's all in the controller.

-

Can a worn case/hook prevent adjustment of case opener lever.

AlZilla replied to beefy's topic in Leather Sewing Machines

VID_2026-01-28-19-22-59-580.mp4 I'm not sure video of my 111w is going to be very instructive. It looks a lot like yours, only with more motion. -

Can a worn case/hook prevent adjustment of case opener lever.

beefy replied to beefy's topic in Leather Sewing Machines

Fantastic, great to be on the same page as everyone. Yes, I agree. The new hook arrived a couple of days ago but I won't get a chance to swap it out until hopefully this weekend. I will create video #2 (the "after" video) when it's done, and hopefully I have a flawlessly working machine. The best part of all this is what I'm learning from you guys, so thanks very much everyone for your kind help.

.jpg.d60258221c476480a6e073a8805645bb.jpg)