All Activity

- Today

-

Were you ever able to figure out the cause/solution of the tension issues? After taking it to the shop? Having the exact issue with my new-to-me PFAFF 1245 right now. It was running amazing and then I thread jammed it, threw the safety clutch (didn’t even know what it was at the time), retimed it according to the adjustment manual to best of my knowledge and the bobbin thread is looking exactly like yours. I tried tightening the top thread tension to see if that was the issue and it didn’t work. Tried loosening bobbin tension, nope. Ugh.

-

That is a reasonable price

-

Once, I was teaching a classroom of kids about the many different kinds of hammers a woman came to pick up her boy early. I was just finishing up when she came over to me and said Are all of those hammers yours I said Yes, they are. She then said If you were my husband, I would kick you right in the ass I asked her why, and she said in a heavy Irish brogue Why would a man need more than one hammer? after I explained just the hammers on the table, she got the point. She said to me Wow, I never thought of that. LOL to Hondo Man's point, you don't use a 22oz waffle head framing hammer for finish work. or a tack hammer for framing. LOL

-

I think that like many good tools it can be used for many applications other than the primary one

-

Ah! Evidently something to hold a seal while you're carving it. Thank you! Ey! Belli ki onu oyarken mührü tutacak bir şey. Teşekkür ederim!

-

-

Our friends at google say it means "Clamp for engraved signature seal". I haven't a clue and I'm not clicking the link. @Veli, the language of this forum is English. It would be appreciated if you use a translation service. Thank you. Bu forumun dili İngilizce'dir. Çeviri hizmeti kullanmanız memnuniyetle karşılanacaktır. Teşekkürler.

-

Kazıma imza mühür için kelepçe https://ulusalbayrak.com/menudetay.php?id=1156

-

I know this is a year old, but I use the $20 rotary cutter sharpener from Wawak to extend the blade life https://www.wawak.com/cutting-measuring/rotary-cutting-tools/rotary-blades/tri-sharp-dual-rotary-blade-sharpener/

-

1.MP4 1.MP4 Here is an example of digital tooling using procreate on the iPad and the apple pencil pro. I have a tutorial on my YouTube channel @thirdbranchleather if you want you know more.

-

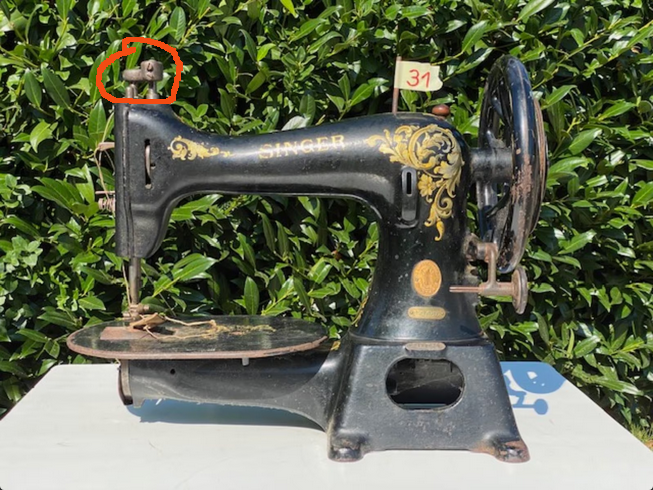

Singer 153w103 question

Texas Leatherworks replied to Texas Leatherworks's topic in Leatherwork Conversation

So I checked the flywheel screws and they were tight. I adjusted the presser foot just a little. I change the size of the thread from 138 to a 92 and then it started stitching. I have used 18 in this machine before with out any issues. The machine is 73 years old so i can understand it is getting worn out. I'm 70 and i am feeling the same way. Thank you so much for the response and the suggestions. SO far it seems to be working. -

Tutorial, replacing zippers in riding boots.

Mulesaw replied to Mulesaw's topic in Shoes, Boots, Sandals and Moccassins

Thanks, it works now 🙂 It is interesting that there are so many different types of zippers. I never thought about being able to configure a zipper, but I guess that if you are going to produce 100.000 jackets, you might as well choose something that you think looks good instead of solely relying on a standard configuration. Brgds Jonas -

MatthewWHuston joined the community

-

Shawzee joined the community

-

It's very odd that it'll pierce the leather without thread but just stop when you thread the needle, but the hand wheel turns. There's a cover on top right next to the hand wheel. Open it up and see if the arm shaft is turning when it won't pierce the leather. I wonder if the needle bar isn't clamped tight ... Still very odd behavior.

-

James Arness (the actor portraying Matt Dillon) was trained, like many other actors, by Arvo Ojalla, a noted holster maker and quick-draw artist of the time. The holster and belt were probably from Ojalla's shop also, as he was the source for a lot of western TV shows and movies. In the opening scene in every episode Mr. Dillon is faced off against a man for a street duel, and that part was played by Arvo Ojalla. There is a spoof version of the opening scene you can probably find on U-tube in which Dillon faces off against Ojalla, then Dillon gets shot and collapses. Otherwise, a close rendition of the usual episode opening, but Matt Dillon lying dead in the street. They were all probably having a little fun that day. James Arness was a brother to actor Peter Graves, of the original "Mission Impossible" series and some of the later movies. The original radio show "Gunsmoke" featured William Conrad (Jake and the Fat Man) as Marshal Dillon. Alongside Arness in the earlier series as his sidekick was Dennis Weaver as Chester. Later years featured Ken Curtis as Festus Hagin. Mr. Curtis grew up in Las Animas, Colorado where his father was sheriff of Bent County, and spent his teen years tending to the prisoners in the county jail overnight. Went on to a singing career with the Sons of the Pioneers prior to WW2, then went into acting with several excellent performances. I was fortunate to meet Mr. Curtis several times during the 1980s and 1990s, always found him to be a very pleasant gentleman. Just about everybody in show business had a role in a Gunsmoke episode at some time over the years. Burt Reynolds had his first significant, and recurring, role. Carroll O'Connor (All in the Family) played a number of characters. You name the actor of the period, he probably appears in Gunsmoke. Nothing about the show "Gunsmoke" is remotely authentic in terms of location, firearms, holsters, or anything else. Pure Hollywood entertainment for the masses.

-

Binding with a right angle binder on a walking foot machine

Dave9111 replied to Dave9111's topic in Leather Sewing Machines

Great! Thanks for the tips and the pictures. Ill try that out. Very nice work! Do you use right twist thread in your left bobbin on your two needle machine? - Yesterday

-

Leather_Hide_Scrap joined the community

-

I think thats one I've sent to the posters

-

Singer 153w103 question

Texas Leatherworks replied to Texas Leatherworks's topic in Leatherwork Conversation

Yes I can turn it when it stops and the needle will lift up to get the material out. I will check to see if the flywheel is lose. Great suggestion. Thank you -

Water Spots

fredk replied to Historicalbeltworks's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

They are 'ruined' now to you. I'd suggest using clean water and giving the affected areas a real wetting and then letting it slowly dry out - days not hours That always worked on items that I had water-spots on -

Both machines have an additional short bar connected from above to foot bar. I am not really shure about function My Singer 34(pre34 model) does not have it At 34, it seems to do nothing, until food is lifted (or not really much) The 45 lifts foot on it's own after each stitch. and so the whole device does Other models known having this are for example 16KSV11, 16KSV23, 34K5 (not all, due model change or remove), 34KSV5, 45K48, 45K53....

-

I think your tooling is incredible. But I think your paint/dye work is equally impressive. Even when enlarged I don't see any overflow on adjacent areas. You obviously are very meticulous. Maybe you could share any tips/tricks. Very good work. Something to be proud of.

-

...actually, only precice Singer source says "alternating presser" ,not "walking foot" so, same as my Singer 15-39, differences are: - 15-39 is the backside foot the pulling one, jumping after pull forward, while 78-3 front foot is pulling in a circle move. - 15-39 has feed dog (single line, as also for leather), no needle feed (see pic) Now here is the question (or are the questions): What exactly is the difference of walking foot and alternating presser? I have here two "Singer walking foot attachments", having an inner and an outer foot. But I am not shure about that. My Singer 29 (long freearm shoemaker) has, what I would call a walking foot, (pulling after stitch back, when needle entered cloth/leather, it's going up and in ordinary position) Also Singer 16 KSV 11 has a single foot, but some do not call it walking foot. ----------------------------------------------------------------- Does anybody have a picture of Singer 78-3 (maybe also other do it) from backside? My machine has close to presser lever a loose plate with 2 holes at upper end. Ok, machine lies flat on ground, I forgot to rotate the image to normal stand

-

I have a Kenmore 158 that I used to use in my shop when I had to sew cloth and linings. It is a good machine and was well built. I don't know about the availability of parts though. I think they are strong enough to sew soft leather, or to sew patches onto vests, but not over pockets. The Adler you have is a 30-70, not the other way around. ;-) It is a great machine for sewing patches over sleeves and pockets, or for sewing in zippers.

-

The cb3200 is one of the 441 class sewing machines, but, at 1/2 inch, it has less thickness capacity than the cb4500 and similar large models. The arm is shorter too, measuring in at 10.5 inches. Other than that, it uses the same needles, bobbins and thread. However, the Cowboy raised holster and stirrup plates are too tall for the 3200 due to its lower thickness capacity. Further, the optional drop-down edge guide doesn't fit on the 3200. If most of your projects will be between 1/8th and 1/2 inch thickness, this machine will serve you very well.

-

Do you mean the hand wheel just spins and the rest of the machine stops? Maybe a safety clutch problem or the hand wheel is loose on the arm shaft? If the belt is slipping, the solution is obvious ... Can you turn it through by hand when it stops?