All Activity

- Past hour

-

That makes sense. I guess I'll call it the "Apparently Singer 144 Winger" or "Singer 144 Without-the-family-tree"

-

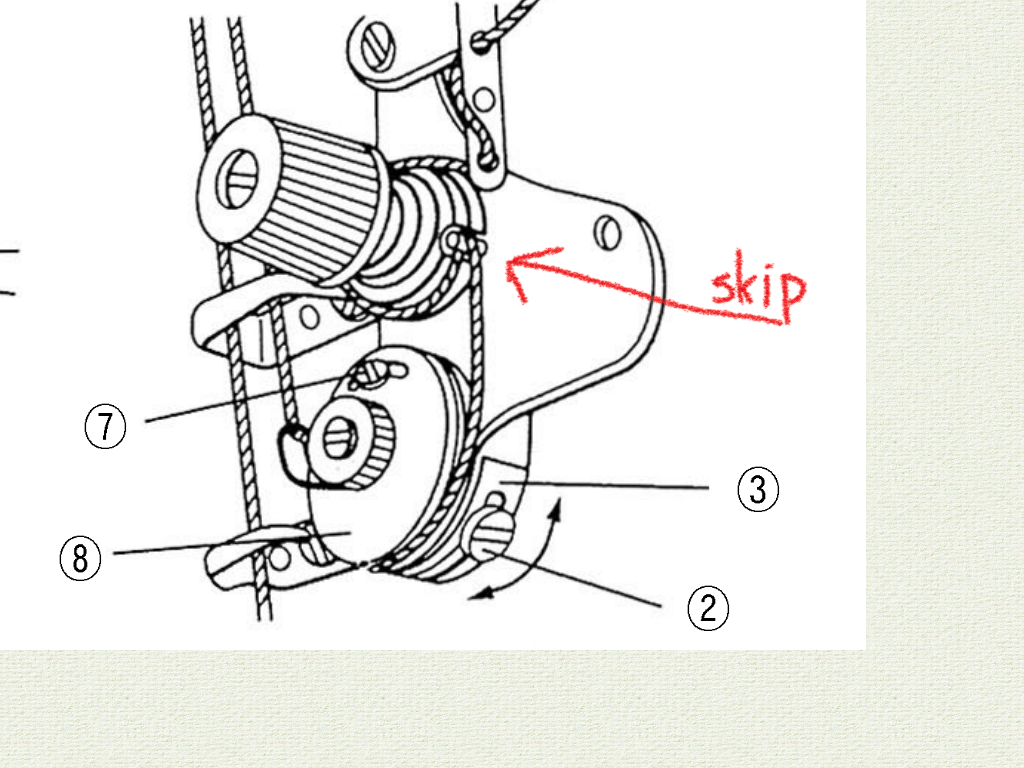

Make sure you're going counterclockwise around the thread tensioner. (one of the drawings in the manual makes it look like you go clockwise) One thing that the manual does not show but that is actually important is that the thread needs to go between the tension discs, not around them. The other thing I would change is I would skip going around the post (see attached photo with arrow) that prevents the tension discs from spinning. (Unless you're looking for ways to increase the maximum amount of tension you can get.) If you'd like to send a photo showing how you've got yours threaded, we can let you know if it looks right. The components are quite similar across LOTS of machines. Also, is it making good stitches?

- Today

-

Best source for clicker dies?

wizard of tragacanth replied to wizard of tragacanth's topic in Leather Tools

Thanks dikman. Yes, I did see the ad... and now I am seeing one for Tippmann. However, I am looking for personal experiences and recommendations. Ads do not give me that. Ads do not tell me if the products are reasonably priced or if they provide good customer service. Just looking for more info. -

Nice looking stuff, I like the pocket sheath. I made one myself, it's not shaped the same but does the same work., I also carry a small tin of cotton ball /Vaseline mix and a short striker made from a hacksaw blade with my ferro rod it will start a fire in seconds wet or dry.

-

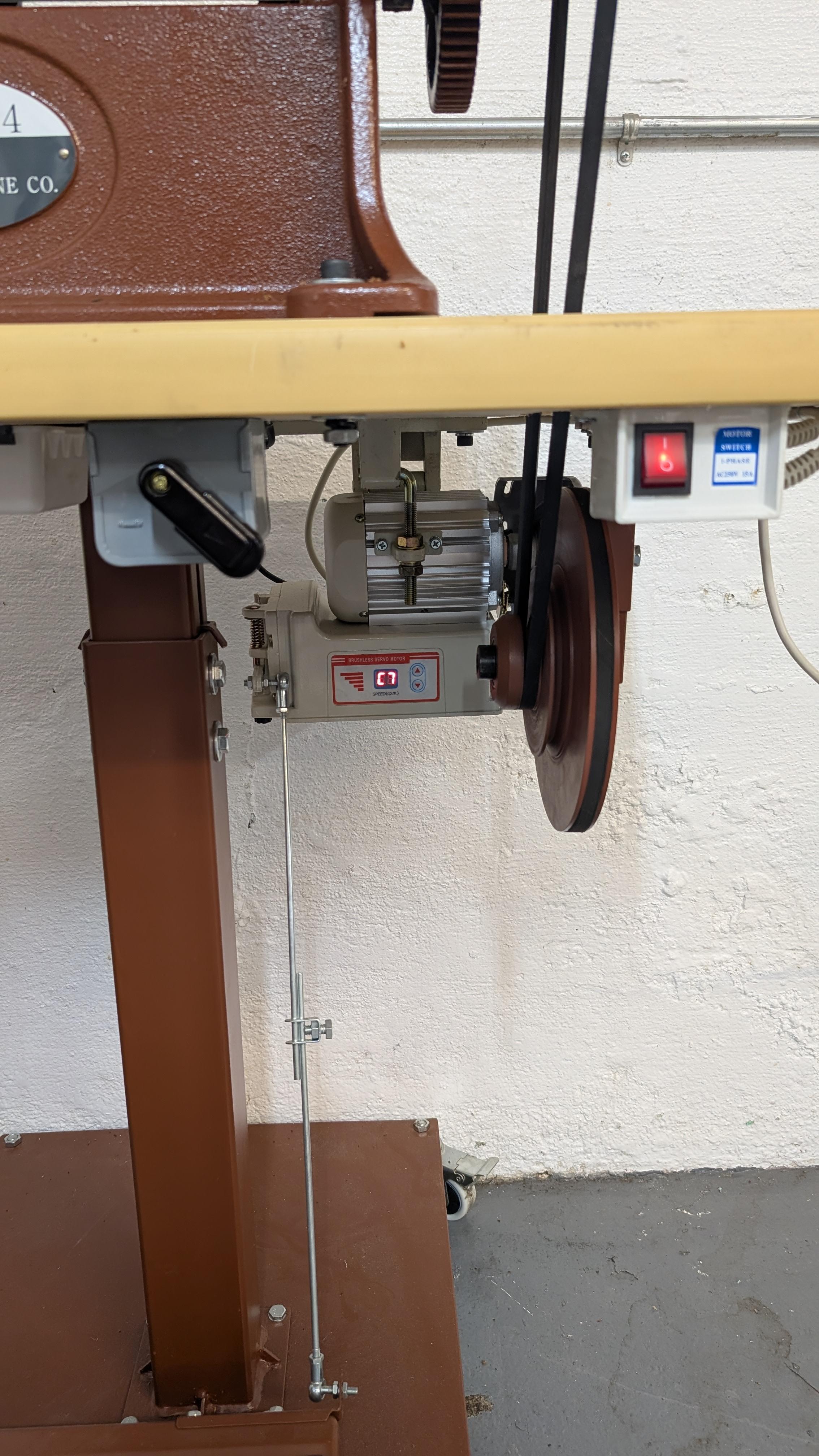

Yeah, servo motors and their controllers are the Mysterious Black Box of sewing machines. They're all just different enough that most don't dare mix n match components and the manufacturers give us just enough information to operate them. I'm surprised the electronic tinkerer crowd hasn't started dissecting these things. I've seen them being retrofitted to lathes and drill presses.

-

very nice work my friend.

-

Hi all, Have had this Cobra Class 14 in the shop for a couple years now, had served me well, but now just taking up space I don't have. My loss. Looking for $2800, retails currently for over $3600. Everything works great, good clean blade, reversible motor. Located in Rhode Island. Have never shipped anything this size, would prefer pick up if possible.

-

I've used that method myself to get even spacing of my stitching holes. Just used an ordinary needle and then followed up with an awl for saddle-stitching (used an old Singer hand-cranked 201).

-

Been thinking on this You have a sewing machine? put a 'leather' needle in, put leather under needle and turn machine manually, without thread. That will punch your holes

-

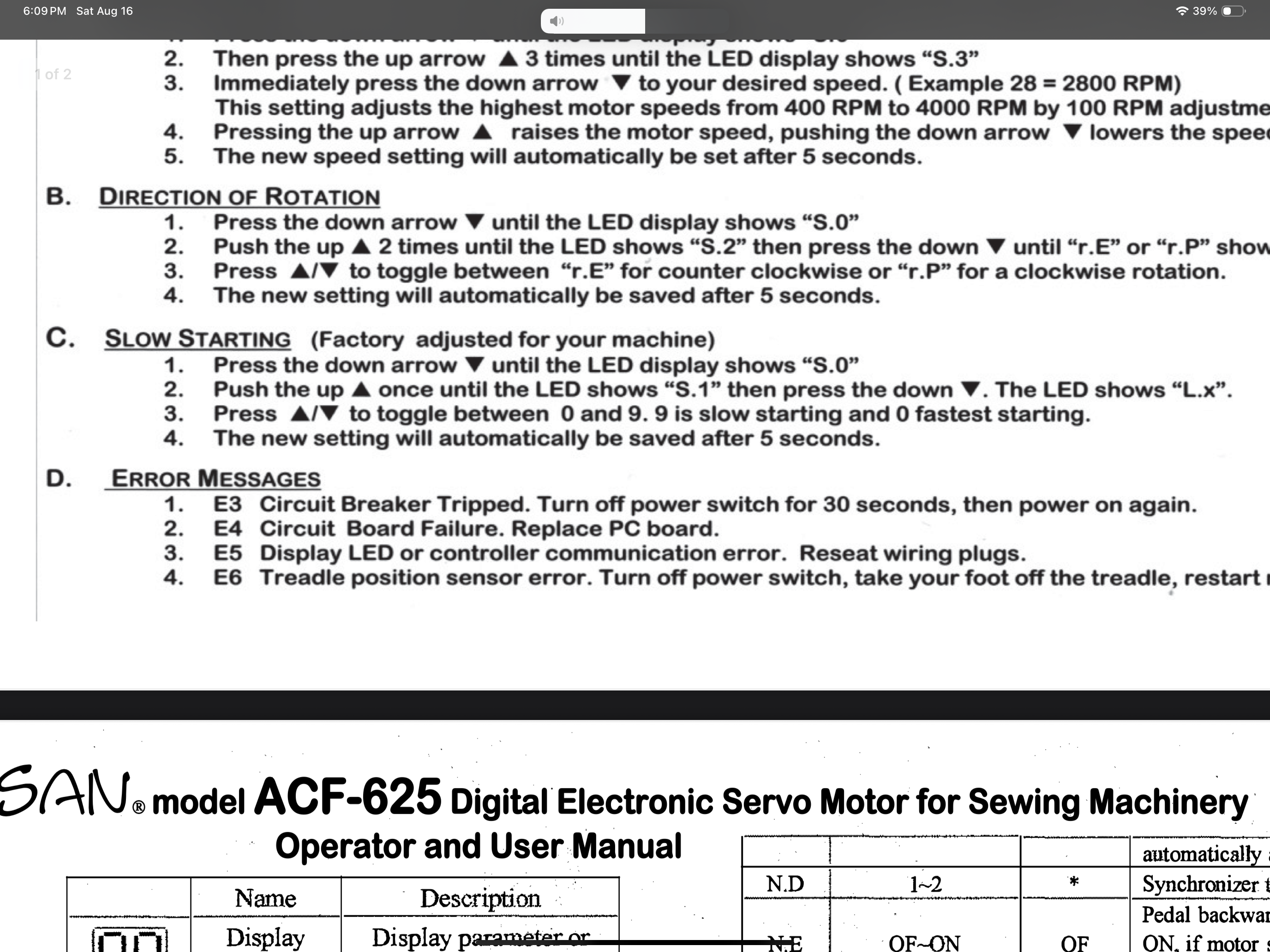

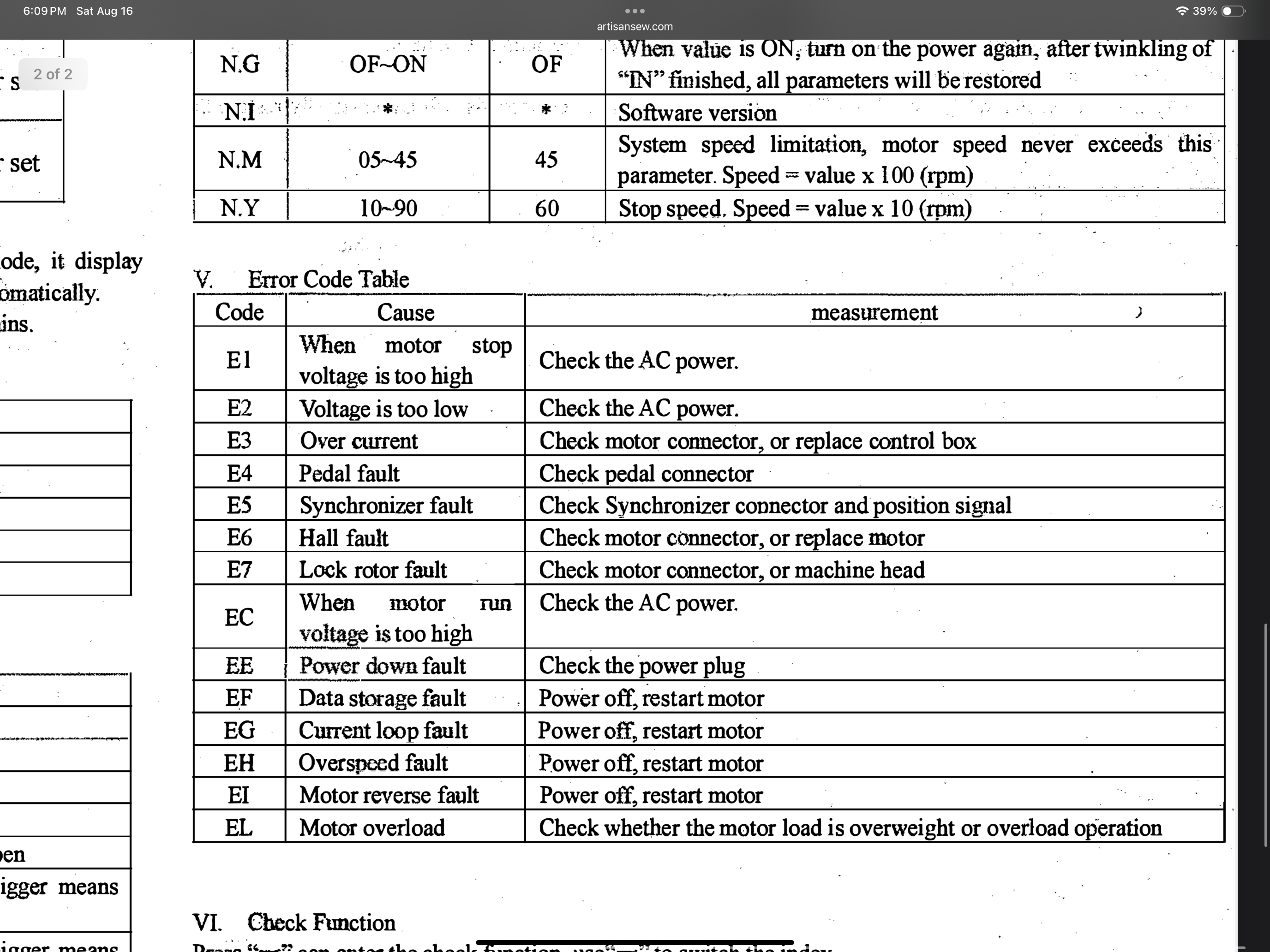

Thank you for your help. Unfortunately I am stuck. I cannot reset to factory because it goes straight to Er 4 and does not let me do anything. I checked tye connections and the pedal: everything seems fine. I have not opened the controller yet but I am not sure what I would be looking for either. it is surprising how little info I can find about this controller. I’d think they must have sold a few of these. When I purchased I was not overly impressed by the interaction with the store people. They had a machine in the back of the store they wanted to sell me but it was very dusty and I asked if they had a new one. They told me ti go back the next day and I am pretty sure they just got the dust off that one and pretended they put a new head on. The whole thing felt wrong but I thought that these are pretty strong machines so I should not have any problem: I did not even consider the electronic parts. I hope they will be able to help me out on Monday but I wonder if they just sold me a lemon. Anyhow. Thank you for your help.

-

Montanadave joined the community

-

Is this still for sale?

-

Everything looked fine earlier but I will look better when i get home. The unit gives me the error even if nothing is plugged in. On a side note, i did damage the cable that goes from the unit to the pedal, it took off some insulation. I’ll check it. I hope tat’s the problem. And I’ll open the pedal too. do you have the same machine?

-

You may have a broken or disconnected wire going from the pedal box to the controller. The most likely location is at the connector where the pedal plugs into the controller. Check the continuity (using a multimeter) between the three wires that come out of the pedal box. (On my digital servo, there's about 1.2 mega ohms between any two of the three.) If unable to test continuity, at least visually inspect the individual wires from the pedal to the control box. Where the individual wires go into the connector on the back of the control box, make sure all the wires are connected. That is, none broken. Take the cover off the pedal box and make sure nothing is amiss inside. (Magnet still connected to moving arm) My $.02

-

Weaver makes nice clicker dies as well. Reasonable priced too.

-

You don't need a proper leather working awl but could use one of these pokey-hole tools They can be bought cheaply. Put your leather over a plastic cutting board and push the pokey-hole tool through

-

So, I turned on the machine today and I keep getting an error, Er 4, on my controller unit. THe machine won't run. I hav eto sew something for a show next weekend and am trying to find the fastest fix. If anyone can help I would appreciate it. I don't understand the manual. From the controller manual, E4 means the board needs to be replaced. But a few lines below it says E4 is the pedal. I get the message even if the pedal is not connected. Anyone knows what can be going on? I emailed and called the store but it is Saturday so no luck. Is a controller board supposed to fail so soon? Should I expect this to be replaced under warranty? I am not even sure what the warranty is on this machine.

-

Oh yeah, it'll be harder to sew. But it's fairly thin leather. You could pre-punch the holes with an awl

-

If you go to google . . . search video: concho belt you can watch videos for the next several hours May God bless, Dwight

-

Its not quite as bad as that....you can still have handguns if you are a member of a shooting club. Roger

-

Thank you both for your help. Will definitely give hotter water a try. I've only used plain tap water that was fairly cold. Will hotter water make it harder to sew? I'm only making about 4 pairs of holes near the fold so I'm just brute forcing a sewing needle through. Will I need to pre-punch the holes before using the hot water? The idea of giving my little duckies "armored" beaks is a hoot and will make for a great 'story' for them.