steelhawk

Members-

Posts

372 -

Joined

-

Last visited

Contact Methods

-

Website URL

http://www.bearriverholsters.com

Profile Information

-

Gender

Male

-

Location

Utah

-

Interests

Writing my first novel, fishing, shooting, archery, ham radio, hunting, photography, grandpa-ing

LW Info

-

Leatherwork Specialty

Holsters and accessories

-

Interested in learning about

Holster Making, Belts

-

How did you find leatherworker.net?

Defensivecarry.com

steelhawk's Achievements

Member (2/4)

-

It was, but the $3500 made up for it.

-

Here's a picture of the holster I made with the tools I wrapped. With the vet wrap I still had good control of the tools.

-

I had to basketweave stamp 25 holsters. To help relieve the pain to my thumb, I used vet wrap and greatly enlarged the tool diameter.

-

Section 2 looks like what I accidentally did. I will fix it tomorrow. Thanks.

-

My machine was sewing just fine. I checked the bobbin and it was nearly empty. I didn't have a spare, so I put it on the bobbin winder. I did something while trying to bump the speed up so it would get done sooner. Now the machine goes in reverse. I don't know what I did or how to undo it. Attached is a pic of the motor I have.

-

Sorry for the delay in responding. I've been under the weather, but am on the way to recovery. Thanks for the responses. The gun is a Glock 45 with a Holosun sight. Since my first post I've done more research and even made a test holster from belly leather. The customer liked it and I only need to make minor tweeks to the pattern. He ordered several of them. There doesn't seem to be much to do differently other than a large cutout for the sight, and getting it in the right place.

-

Nice job on the tool rack. I'm still debating my options. I have a houseful lately with my daughter and son-in-law living with us. They have five kids, ages 8 to 18. They all want to watch me work. I've done lots of leather projects with them, though.

-

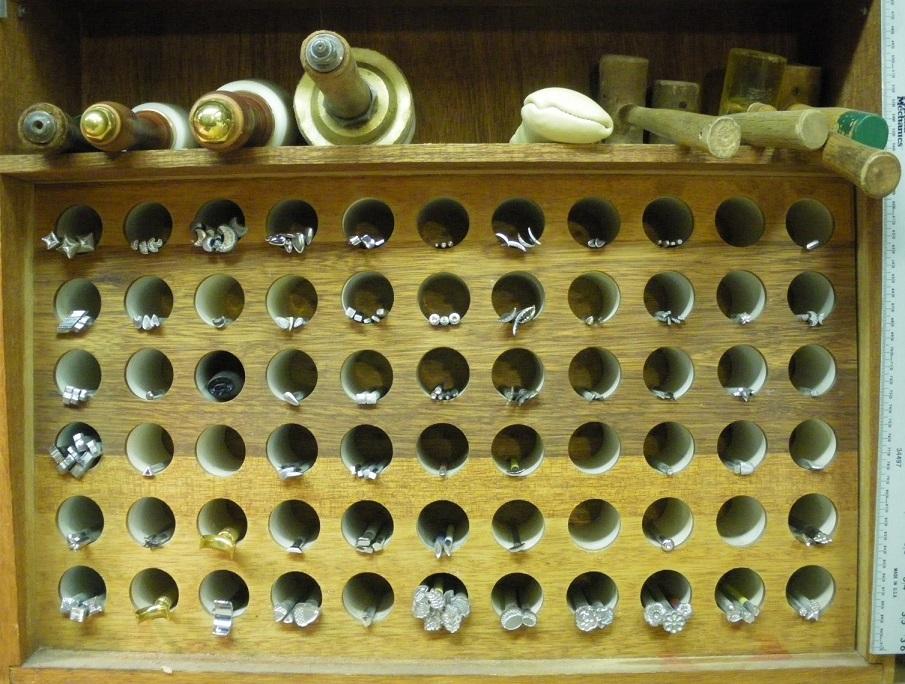

This is what I currently use, which is too small. I have a fourth tool rack elsewhere in my shop that I made as a teenager, longer ago than I care to remember that I used forever. There are over 60 tools still in it. I want to get down to one tool rack for my stamps. Next picture. I found this tool rack somewhere on this forum and am considering making something similar, but am not sure I will like using it. My question: If you use something like this, how do you like it?

-

Having trouble with a motorized edge burnisher

steelhawk replied to blackmad's topic in How Do I Do That?

The tool you bought runs at 3450 RPM. My understanding is that this RMP level is too fast for burnishing. The burnishing machines I have seen can operate much slower. The Cobra one has a variable speed motor from 2000 to 3450. The machine Weaver Leather sells operates at 1725 RPM.- 5 replies

-

- burnishing

- edger

-

(and 1 more)

Tagged with:

-

Yes, a block to hold stamping tools.

-

My current tool rack is too small. It has about 120 holes and I need about 80 more. I can make a larger one, but I'm wondering if I want a different design. Looking at the tool racks posted here, I've seen some racks with larger holes that hold multiple tools. For those with that type of rack, do you like it? Is it better than your old rack with individual holes?

-

I was able to get close to the OD green color by using 1 part black and 6 parts yellow. 1 in 9 parts is also close. Turns out the customer doesn't own the gun yet, so there is no order placed. In a couple of weeks I'll take a trip to a few larger gun stores and take my sample with me to compare colors and see which is the best match.

-

An application of neatsfoot oil will also change the color. I have to take that into consideration as well.

-

I believe that is the color I want.