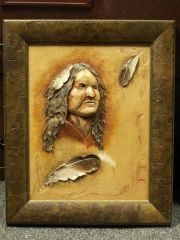

I'm glad you liked the mountain lion project and are interested in trying the technique. As has been pointed out, there are some free tutorials I've done here on the forum and also on my website. There are also detailed instructions for several different projects for sale on my website.

To start a project like this, it is carved just as any regular flat carving. All the cutting, beveling, shading, etc is done. On this project, all the hair was cut with a multi blade knife (5 exacto blades in a handle) and a scalpel to create more lifelike hair. To get the amount of lift that was achieved in this picture, certain parts of the lion were cut loose from the background leather. This is started before the project is stretched. I use a Pro Petal tool to start cutting these areas loose (some people use a scalpel). I made shallow cuts around the ears, lip, right side of the nose, and the paw and claws. These cuts are at a shallow angle so they slice into but not through the leather and go about 1/8th inch deep at this time. By making these initial cuts now, it will be easier to cut those parts loose after the leather has been stretched.

If you turn the project over, you should be able to see a dark line from your beveling. Darken that line with a marker or pen. You will not want to stretch beyond that line. Then wet the leather on the back side, inside that line. You don't want to soak the leather, just get it wet. While wetting the leather on the back, watch the front. As soon as moisture starts to show on the front, you've got enough moisture in the leather. Begin stretching the leather by placing a marble on your bench. Put the leather over the marble, place a finger on each side of the marble and push the leather around, rolling it over the marble to begin stretching the leather. Continue rolling and stretching to get the areas you want to stand out. The cavity created by stretching the leather is then filled with a putty made of ground up leather and rubber cement. If you want a lot of stretch (more than 1/2 an inch) it is probably best to fill the cavity in layers so that the putty will dry. Once the putty has dried, you can do more stretching by rolling over the marble again. Continue stretching and filling until you get the desired shape.

Once the basic shape is achieved, you can cut parts loose like I did on the lion project. There ears have been completely cut loose from the background leather. They are then shaped and stiffened by adding putty to the back sides of them. The paw and claws were also cut loose and shaped with putty on the back side. The log underneath the lion's paw and the rocks and grass are separate pieces of leather, shaped and added to the picture.

I hope you can get a basic idea of what I've done here. It makes a lot more sense when you can see it being done. Once you learn the basic techniques and what you can do with them, you can have a lot of fun making your projects 3 dimensional.