-

Posts

58 -

Joined

-

Last visited

Profile Information

-

Location

California

-

Interests

Most things involving tools.

LW Info

-

Leatherwork Specialty

Screwing up

-

Interested in learning about

All I can

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

7,317 profile views

RockRash's Achievements

Member (2/4)

-

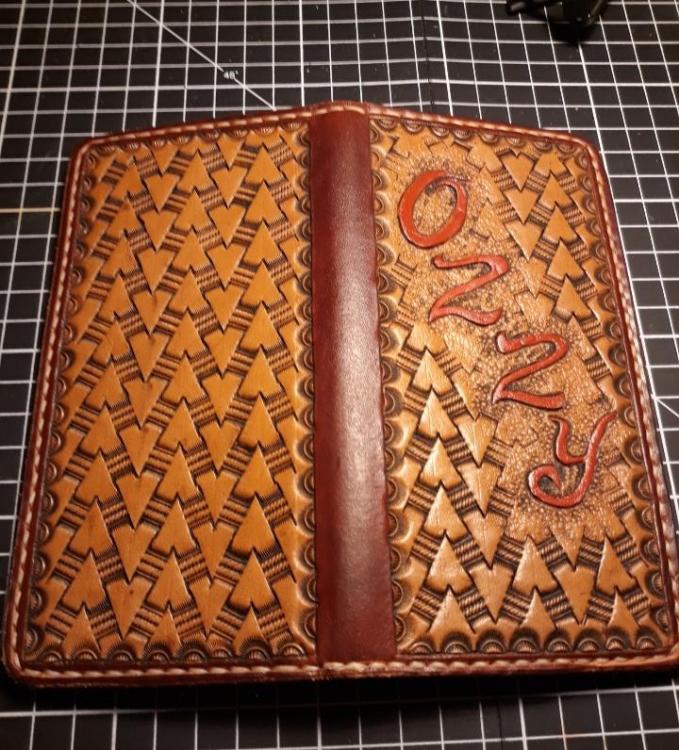

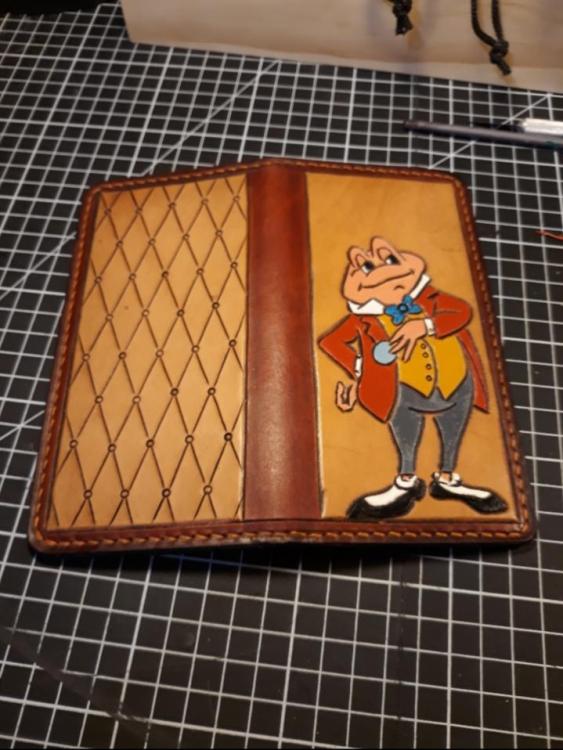

This is my second belt and wallet, so to get some more practice I offered to make a belt for my buddy. I decided to make him a matching wallet to go with it. I used chicago screws instead of rivets on this one ( thanks for the recommendation Dwight) anyway let me know what you think.

-

I got a reply from Weaver. "Thank you for your email. Yes, we do still offer sharpening services for the Master Tool Punches. You can just send the punch in along with a note that you would like to have it sharpened and your contact information. Once the service is complete, they will reach out for payment and ship the item back." So for anyone interested they still offer a sharpening service.

-

How long do I really need to let Pro Dye dry before applying finish?

RockRash replied to Sarina's topic in How Do I Do That?

When I dip dye I typically give it a few hours depending. If using a dober 30 minutes is usually fine. That seems to work for me. -

I'll give them a call on Tuesday and report back. The problem is I didn't buy it directly from weaver. I bought it online from a second party seller. I got it almost half off, that seemed like a great deal. However I didn't buy it from weaver so I dont expect any help from them through warranty.

-

It's a frustrating situation. Lol

-

Thanks! It's a great size and knife. I just need more time behind it. I'm planning on using it a lot on my net few projects so I can get more comfortable with it. Diesel Tech, keep checking back his inventory seems to be resupplied fairly quickly. I had the same thing happen a while back with his buck stitching chisels.

-

Thank you. I have seen it done before and always liked the idea. I will say its very satisfying sliding it in the sheath and snapping the snap. Diesel Tech, it's a great knife, very sharp from makers. I'm sure my complaints are my lack of experience with it. ETA: sorry I screwed up the quote.

-

RockRash started following Doc Reaper

-

I bought a weaver punch online for a great deal. After receiving it I found out why. Its dull it takes a a ton of pounding to punch through 8oz leather. Nothing like the other punches I've bought directly from weaver. The edge also looks uneven again not so with my other weaver punches. I've tried stroping but no luck and sharpening something like this is out of my wheelhouse. I know weaver used to have a sharpening service but I can't find any information on that. Does anyone know who I can send this to? A few pictures to show the edge

-

I did lol. I just do this as a hobby and my wife got me the makers mark for Christmas. It has my real name on it and call me paranoid ( I probably am over paranoid) I dont want my real name on a public forum.

-

Thanks. The knife is the small round knife makers leather supply sells. I'm no expert (this is my first round knife) and I know I need more time using it. This particular knife doesn't feel all that comfortable. This was the only knife I used for this project , I want to get proficient with it. If I could go back I'd order a larger knife. This one is so small ive ended up cutting myself a few times because my fingers are so close to end of the blade. Reference photo

-

I have been wanting to make a round knife sheath for a while now. I decided to try out some new stamps and airbrush I got for Christmas and I came up with this.