-

Posts

85 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Willbury

-

Atom Clicker 3-Phase To 1-Phase Conversion

Willbury replied to Yanni's topic in Leatherwork Conversation

Reviving this old thread, with the hope of getting some more info on using VFD's with clicker presses. From what I can tell most of clicker presses (modern types) that use a 3phase power to run the motor run the electronic control portions of the clicker on single phase power. The 3 phase power is run through a transformer with converts to single phase for the controls. Does the VFD output have any detrimental/problematic effects on the single phase electronics of the machine? -

3 Phase to Single Phase Clicker conversions.

Willbury replied to Willbury's topic in Leather Machinery

I'm sure the VFD will run the motor just fine, where I'm more fuzzy on this whole situation is the electronic controls. As I understand it (looking at some wiring diagrams) the electronics in the machines are run on single phase power converted from three phase in a transformer. What I'm wondering is if the frequency from the VFD is not correct will it mess up (fry) all the controls? -

3 Phase to Single Phase Clicker conversions.

Willbury replied to Willbury's topic in Leather Machinery

I'm looking at machines on the used market and will do the conversion, whatever it may be, myself. -

Looking for a bit of advice. I'm in the market to upgrade my clicker to a larger machine, something around 25tons. Everything I've seen in these larger machines are 3 phase, which I don't have in my shop. I know the traditional method of doing a conversion would be to use a Rotary phase converter, however I'm under the impression that some people are using VFDs(variable frequency drives). Is anyone here using a VFD on a 3 phase clicker? My biggest question is in regards to the electronics potentiometers etc in the clickers that tend to run on 110 and can go a bit awry with some conversions.

-

Adler 205-370 Synchronized binder supplier?

Willbury replied to Willbury's topic in Leather Sewing Machines

Thank you. I've emailed Hightex so we'll see what they say. -

Adler 205-370 Synchronized binder supplier?

Willbury replied to Willbury's topic in Leather Sewing Machines

It's a real bummer, I was just finalizing some details to get a custom made one from them but looks like I'm out of luck for now. -

Hello, I'm wondering if anyone knows of supplier for a synchronized binding attachment for an Adler 205-370. I have been talking with Kwok Hing in Hong Kong about ordering one but it seems they have gone into a partial shutdown due to the corona virus outbreak and are no longer responding to me. Any suppliers in North America or Europe that might have/make these?

-

205 Adler Clone Recommendation for Binding Work

Willbury replied to anvlts's topic in Leather Sewing Machines

Question for you Uwe. On the KH kit is it possible to replace the actual folder with different size/fold options? Specifically wondering if I could replace the folder with a single fold raw edge option? I can't quite tell but it looks like the folder bolts onto the assembly that then screws onto the synchronized plate, am I correct? -

SOLD

-

That would be a bit far! They are indeed awesome machines. I have 3 other kwikprints in my shop, a model 55, 64; and 86.

-

This is a kwikprint model 64 machine for hot stamping, gold foil stamping, debossing and other printing. Fully functional with a sliding print table and height adjustable print head. The large curved base allows for stamping on large bulky objects. The model 64 was specifically marketed for stamping on luggage. The machine is heavy and will need to be picked up. It can be disassembled for easier transport but must be picked up locally. located in Ottawa, Ontario. Asking $850 CDN

-

Anyway to sew this bag seam with a Machine?

Willbury replied to Willbury's topic in How Do I Do That?

Very interesting. Do you flip the bag to apply the stiffener or just put it in as is? Thanks again for sharing. Will -

Anyway to sew this bag seam with a Machine?

Willbury replied to Willbury's topic in How Do I Do That?

Very nice, also a good tip on the tension disc front, never thought of that. Any pics of the gusset area stiffener you used? -

Anyway to sew this bag seam with a Machine?

Willbury replied to Willbury's topic in How Do I Do That?

Thank you, very informative! I hadn't really considered how pliable that leather might be before the lining is added. Also those Robin Machines are rather interesting. I've managed to do this style seam before with my patcher but as you mention the stitching quality/consistency really isn't there and I abandoned the idea. I recently added a narrow 17" post bed to my shop, so maybe I should give that a shot too with a more pliable leather. To confirm, you are sewing this black bag entirely on a cylinder bed? -

Anyway to sew this bag seam with a Machine?

Willbury replied to Willbury's topic in How Do I Do That?

Maybe I’m missing something here. So this bag is made essentially of three pieces the front the back and the one piece sides and bottom. I can see how you could sew the front to the bottom sides. Once that’s done though it seems impossible to repeat the operation sewing the back face on in the same manner. -

Anyway to sew this bag seam with a Machine?

Willbury replied to Willbury's topic in How Do I Do That?

To clarify I meant the main u shaped seam which is mirrored on the front and back of the bag. It appears to be a simple lap seam. -

Hello, I can't see how you would machine sew this type of seam (other than by hand) on both sides of the bag and wondering if I'm missing something?

-

Tippmann Aerostitch II still available?

Willbury replied to DavidMillsSaddlery's topic in Leather Sewing Machines

I owned and used one of these machines for a couple of years. It was powerful for sure but I never loved it, it was actually a bit scary to operate. Its operation was finicky. Also it was really annoying not having a hand wheel, the needle is either up or down and you don't realize how frustrating that can be, especially if you get a jam. It's a relatively loud machine as well (not speaking of the compressor aspect). I know the owner before me (the first owner) had to send the first machine he bought back due to problems that couldn't be fixed and was send a replacement. I sold the tippmann once I got an Adler 205 and have never looked back. I wouldn't consider one of these machines again. -

Suspended Edge Guide for Juki LU-563?

Willbury replied to Willbury's topic in Leather Sewing Machines

I found that as well but am a bit surprised that a Pfaff would have the same hole and stud placement dimensions, if it had been for a 111 or 211 I wouldn’t question it. There’s nothing else online I can find other than this link without a picture so hard to know for sure. -

Suspended Edge Guide for Juki LU-563?

Willbury replied to Willbury's topic in Leather Sewing Machines

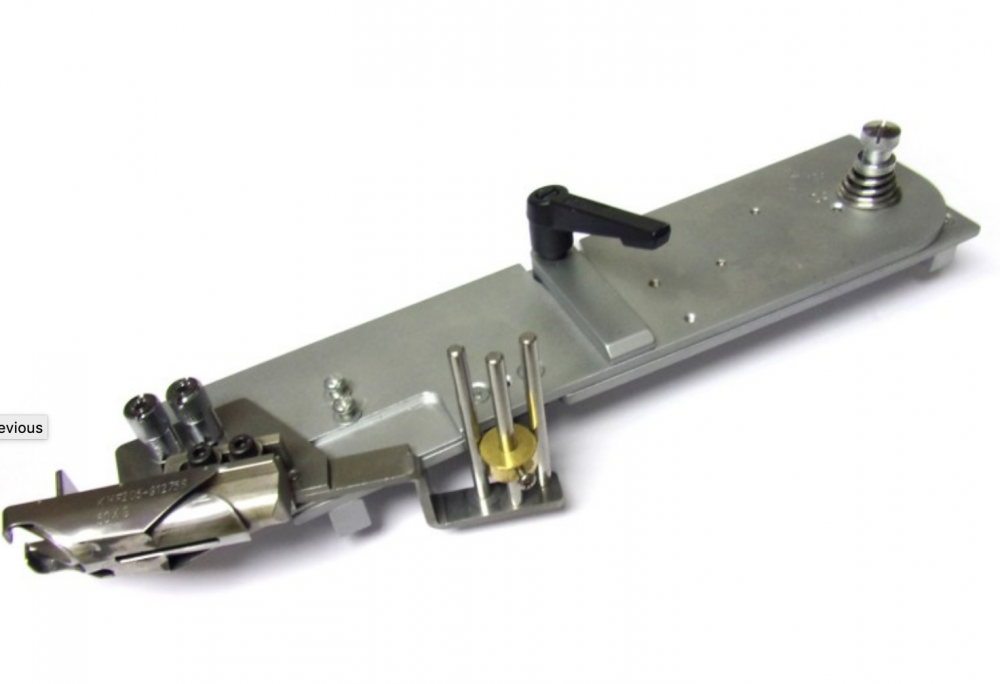

Just wanted to follow up with this thread. I was out a my friends shop today and mentioned the edge guide conundrum for the LU-563 and he pulled this out of his drawer and gave it to me. It uses a single existing hole on the backside of the 563 and is stabilized with the pin that holds the front dust cover closed. So these are out there. This one has the following stamped on it: FAE and then 99-116086-23 if that helps anyone find one -

Suspended Edge Guide for Juki LU-563?

Willbury replied to Willbury's topic in Leather Sewing Machines

This would be perfect, any suggestions where to source a guide like this? -

I'm wondering if anyone has come across a suspended edge guide for a LU-563 or an adapter to use one of the more generic ones. I've drilled and tapped the body on other machines to make edge guides work, but prefer not to go that route if it can be avoided. Anything out there people are using or have come across?

-

All of singers have a hand crank option. I use the crank quite frequently. Some machines likely have the crank wheel taken off, but’s it’s an option to mount on the back pulley or the side of the machine (where I have mine)

-

I've had quite of a number of Singer long arm large bobbin (it's not that big) machines and I still keep one in my shop. I originally had hoped to be using them to sew inside awkward spots in bags, which sounds like what you want to do. I've ultimately decided that it's not really a viable machine to do this kind of work, except perhaps to sew smaller pieces on (patches). It is extremely difficult to get the stitching as perfect as I'd like, as mentioned by others it's hard to get a consistently straight line. Can you do it with extreme care? Yes it's possible but it's hard and very easy to make a mistake. They certainly are a worthwhile machine to have, that rotating head is very useful at times, but if your goal is to use it as a primary machine to sew entire bags you may be disappointed... my two cents. Oh and I pretty much always use 135 thread in mine.