-

Posts

85 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Willbury

-

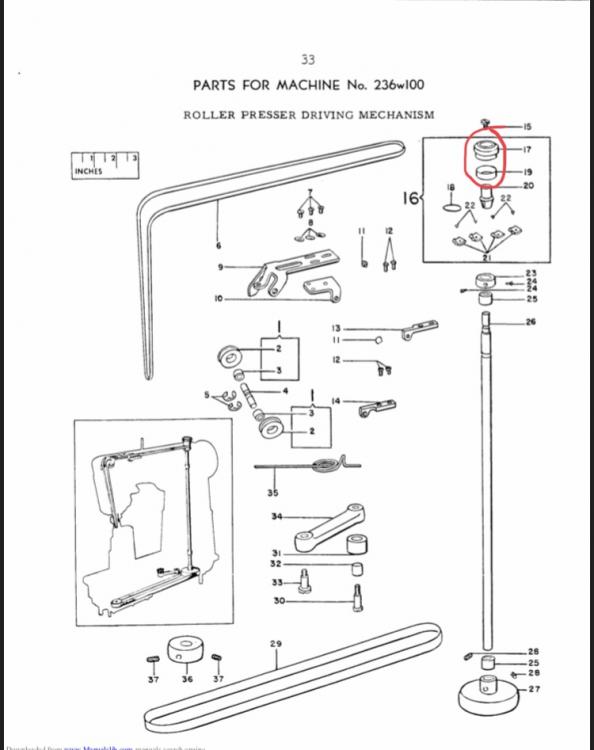

Wondering if anyone has an old damaged machine they’d be willing to sell some parts from, or could direct me towards a source for parts. I’ve circled the two parts from the manual attached. I’m specifially looking for the pulley lock nut #17 and the Segment ring #19 I do also need a connection belt but I have found these online.

-

It ended up being set-up for 794 needle system so needles are fairly plentiful, so that's a bonus. Looks like feet for my Singer 211 fit it as well!

-

I’ll give it a go. Pulled the needle (that came in the machine) out this morning and realize it isn’t a 7x23 system at all, looks like it’s very close (or actually is )to a 794 (7x3) system. Perhaps someone reset the needle bar height or maybe tuftmaster set them up that way. Convenient as 794 are plentiful in styles and sizes. Now to find and replace the giant boat feet with something more suitable.

-

I've had, for a number of years, a single needle Tuftmaster (re-badged Adler 220) sitting in the corner of my shop. I haven't been using it as most of my heavy duty sewing work gets done on an Adler 205-370. The ultra large bobbin on the 220 has piqued my interest of late as I've been sewing a lot of combined canvas and leather projects and the bobbin capacity when sewing much longer seams is very appealing (currently using a juki LU-563 for the work). Doing a bit of reading in old Adler literature it states that the needle system 7x23 is designed to take a range of 170-200. My question is it possible to run smaller diameter needles? I can see 7x23 needles down to 130 available, will these work? I realize the hook may need be moved to accommodate the smaller size needle. Any other reason it wouldn't work?

-

I'm wondering if anyone has any experience adding, by sewing or gluing, a backing to leather to prevent stretch. Specifically if you were to use something like upholstery leather that was slung between stool or chair rails, like a folding directors chair. Ideally I'd be using a nice thick veg tan, but cost may not allow it for this particular project, so I'm wondering what other options are out there. Will

-

Durkopp 291 walking foot machines for sale (22)

Willbury replied to CaptnCaptain's topic in Old/Sold

Ended up with two of these that seemed in quite good nick. Both have the aux control panel and the larger knuckle on the head. For anyone else interested there seems to be two main variations of the machines, those with the Efka controller pad and those without. The ones without the pad had more options on the control board itself, but likely have less functions overall. We’ll see once it’s all plugged in, going to attempt static phase converter route. While there are quite a few machines left but many are missing bobbin cases or have play in the needle bar. Some machine heads had been matched with motors and controls that weren’t original and while they may work just be careful what you’re getting. I would have been tempted to pick up some heads for parts but they don’t have any flexibility in price between machines regardless of condition.... at least right now.- 18 replies

-

- walking foot

- industrial

-

(and 3 more)

Tagged with:

-

Converting Efka 3 phase to single without convertor

Willbury replied to radrider's topic in Leather Sewing Machines

This is a really helpful thread! I was pleased the see the controller is 2 phase as it looks like the static phase converter should work. I have been debating picking up one of these and finally did the long drive down, from Ottawa, and picked up two 291’s (with the bottom knuckle)from the factory yesterday. What’s left is getting pretty picked over, but I believe I got two very good machines. No play in the needle bar at least. Will post some pics when I get a chance. -

Durkopp 291 walking foot machines for sale (22)

Willbury replied to CaptnCaptain's topic in Old/Sold

I’m considering one of these machines but really curious about the functionally without the main control panel. The one I was looking at only has the four buttons (one is a back tack feature I believe) above the needle bar.- 18 replies

-

- walking foot

- industrial

-

(and 3 more)

Tagged with:

-

Durkopp 291 walking foot machines for sale (22)

Willbury replied to CaptnCaptain's topic in Old/Sold

I’m curious, it looks like some of the 291’s have the external control panel and some do not. Is the control panel required for the machine to operate? Or does it give you some additional specific controls? Have any of you considered using a VFD instead of a rotophase?- 18 replies

-

- walking foot

- industrial

-

(and 3 more)

Tagged with:

-

Seam allowance and sewing technique around corners

Willbury replied to Willbury's topic in How Do I Do That?

Finally circling back to this thread I started. I’ve made a few more bags and in addition to skiving I’ve also cut v notches in seam allowance as recommended. Then trimmed the seam allowance down from 1/2” to about 3/8” after sewing. Then added a binding tape. It made a huge difference and I’m quite happy with the result. Thanks for all the tips! Will -

Seam allowance and sewing technique around corners

Willbury replied to Willbury's topic in How Do I Do That?

Ok that makes total sense with the pies vs fans for compassion vs stretch. I have been running binding tape over the seam after sewing so I guess that will get a bit scrunched up after turning the bag. Not such a big deal I suppose. Thanks for the insight! -

Seam allowance and sewing technique around corners

Willbury replied to Willbury's topic in How Do I Do That?

Interesting I wouldn't have assumed the slots went right up to the stitch line. I'm machine stitching these so I would need to pre-cut the slots, and either glue or clamp it together before stitching. Thanks for sharing! -

Seam allowance and sewing technique around corners

Willbury replied to Willbury's topic in How Do I Do That?

How wide is your seam allowance and how close to stitch line do the "v" slots go? Oh and how close together do you make the slots? -

I'm looking for some advice in regards to sewing curved corners into bags. See picture below of one I've just sewn. Typically I've been using a 1/2" seam allowance, but I'm finding it may be too much when doing this type of corner. The material lines up along the stitch line but is much too tight at the outer edge of the seam allowance. It's a real battle to sew it like this and things tend to move around. Solutions I see are, a smaller seam allowance or cutting perpendicular slits in the seam allowance around the corner. Id really like to hear how others are doing this as I'm self taught and just haven't seen how it's done. Thanks in advance! Will

-

Juki LU-563 chrome tan and inconsistent tension

Willbury replied to Willbury's topic in Leather Sewing Machines

The needles I've been using are actually diamond point. One of the other problems I'm encountering with this leather is that the trailing and leading edges of the needle blade are actually developing burrs on them. I wasn't aware of Titanium needles, I would imagine it would prevent that problem, but I'm unsure if it help the knot pulling up. Unless there are some options for different diamond point profiles that would do a better job making that hole bigger? -

Juki LU-563 chrome tan and inconsistent tension

Willbury replied to Willbury's topic in Leather Sewing Machines

Interesting thought, I'll experiment with foot pressure. I did some additional experimentation last night and went down to a #22 needle with the same results. Then decided to try some 69 thread with the #22 set-up, so a very oversized needle. After substantially reducing the upper thread tension, since I was no longer using the 135, the stitching was perfect... My hunch is still leaning towards the leather as the culprit. I'm thinking the hole cut by the needle closes somewhat during the needle upstroke and makes it difficult to pull the knot up into the leather. A bigger needle to thread ratio may solve the problem, but since a #24 needle is not enough and already really over the machine capacity I may be out of luck. I will try the presser foot pressure to see what happens.... -

Juki LU-563 chrome tan and inconsistent tension

Willbury replied to Willbury's topic in Leather Sewing Machines

I thought I'd post back up on this issue I was having. The inconsistency reared it's ugly head again today when going back and sewing chrome tan with the LU563. I then spent hours and tore into the machine and made sure everything was set-up properly and at the end everything seemed fine except the lower stitch once and a while won't pull up into the leather. Even with the top tension near maximum and the bobbin tension as low as it will go. Next I went over and tried sewing on my Singer 211 with the same thread and same leather. Immediately I had to increase the upper thread tension close to maximum and it two was displaying the irregular thread tension on the underside even with the top tension so high. I've come to the conclusion that the issue must be the leather density and the top finish on this pretty basic chrome tan leather. I've been sewing with both topsides facing out and I think it's preventing the thread pulling up properly from the underside. Neither machine has a problem sewing veg tan in the same thickness or thicker and you don't need to run the unreasonable thread tensions to make it work well. I guess I'll have to use a bigger machine. I quickly tried out my Adler 205 which is set-up with 305 thread and it did the job no problem. I wonder if I downsize the needle and thread if it will still work.... -

I just picked up a Torielli skiver this past week from a gentleman who used to run a boot factory in Montreal. Tha machine appears to be in great shape and works well, although I replaced some of the old wiring which was rough. Im curious if anyone knows much about the brand or the machine. Any old manuals about? Looks very similar to a Fortuna and I wonder if parts might be interchangable to some extent.

-

Juki LU-563 chrome tan and inconsistent tension

Willbury replied to Willbury's topic in Leather Sewing Machines

Thanks for posting that, very helpful to have on hand. I had adjusted the inner hook guide arm clearance after Uwe's post and I haven't had the stitch issue since. We'll see if it recurs in the next few days (hopefully not) if it does I'll go back and do a complete assessment of all the adjustments again. -

Juki LU-563 chrome tan and inconsistent tension

Willbury replied to Willbury's topic in Leather Sewing Machines

Thanks for the suggestions, after having another quick look at the machine I wonder if bobbin case opener is causing a slight hang-up when releasing the thread. Timing seems fine and the needle guard does seem to be in the correct position to deflect the needle. I'm going to check this one more time, just to make sure. The funny thing with the needle burring is that it happens on both of the sharp edges of the point (closest and furthest from the machine operator) which makes me question weather it's the material causing it to happen, especially since there's no indication of the needle striking anything on the machine. If it is striking the machine I would expect to only see it on one edge of the needle point. Could these be a bad batch of needles? I'm going to try adjusting that bobbin case opener and see what happens. I'll report back. Thanks again. Will -

Hello, looking for a bit of advice. I've been having an ongoing stitch consitancy issue while sewing two to three layers of approx 5 oz chrome tan leather. Approximately once in a ten inch length it's common for me to have one stitch not pull up into the material. See attached picture. Adding tension does negate the issue sometimes, but it usually comes back. I've noticed that the diamond point needles I'm using also tend to develop burrs on the cutting edges relatively fast and I had assumed the leather density was causing it but wonder if there is something else I might be missing? It doesn't happen when sewing veg tan of the same weight and thicknesses. is it common to burn through needles with chrome tan leather? Would the burrs cause my problem? The set-up I'm using is as follows: juki lu-563 Schmetz 135x16 size 24 diamond point needle 135 nylon thread (not lubricated) These are the needles I've been using.

-

How close to the edge of the arm will it sew?

Willbury replied to Matt S's topic in Leather Sewing Machines

Here's a measurement for an Adler 205-370, just a hair over 1/4" with a slightly modified weaver harness throat plate. -

Right Angle Binding Attachements (source?)

Willbury replied to Willbury's topic in Leather Sewing Machines

I think those may indeed work, as the binder on mine has a spacer under the flange. Can you tell me if this style of binding attachment is designed for a specific kind of binding material or operation. I'm just comparing it to a binder that brings the tape in flat and folds it in the binder. Like the picture below. -

Hello, I've recently acquired a Consew 227 RFS binding machine and I'm wondering if anyone can point me to a supplier of generic binding attachments of different sizes that might work with this machine. I realize that it's very common to have these attachments custom made, but I've seen pictures online of similar binding attachments that are supposedly off the shelf items. Of course I can't find any reference to a supplier only that they can be bought online. The attached pictures show the binder that's currently on the machine.