-

Posts

605 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

BIG D

LW Info

-

Interested in learning about

all aspects of leathercrafting

-

How did you find leatherworker.net?

just searching the net

Recent Profile Visitors

CustomDoug's Achievements

Leatherworker (3/4)

-

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

Not sure if posting a video to this website is as easy as posting photos is apparently, but I shall give it a try later today. Top thread tension: I mentioned earlier that my top thread was difficult to pull (too much tension thru the discs even when loosened).. I found the reason - I'd added a supplemental spring to the tension disc for heavier thread a few years ago (and forgot because I haven't used this machine in so long). I removed that extra spring and now the thread is much easier to pull thru at the end of a line of stitching - however, removing it did NOT improve my stitch length as I hoped it would. Nor did adjusting/centering the feed-dog.. & honestly the stitch length is no better than when I started this thread. Stitch too small at max adjustment w/138 thread. Frustrated. -

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

Duly noted, thanks. -

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

..OK, did both of these over the weekend.. and after a good fight, was finally successful !! So I then made the adjustments to the feed dog and needle bar from Uwe's video posted earlier (thanks again buddy). My needle length may be about 5mm now. Again, I'm using #138 thread - Uwe, can you get 6mm out of 138 thread with your machine from the video? Maybe it's just much for this machine??? NEW PROBLEM - now my machine is not pulling the material equally .. it seems to be pulling the top faster. Is there a common cause for this and adjustment ? -

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

That's a great tip Stelmack, I've made note.. -

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

Hi Uwe.. what an easy to follow and informative video you put together!! It's very helpful and appreciated. After watching it, I've gone from flying high on a cloud to crashing solidly to the ground in defeat. Unfortunately the head of almost every screw on this machine has been chewed up at some point in its life. And, wouldn't you know - I CAN NOT BUDGE the dang screw you alluded to in your video (first one, on the upper body, in the hole under the lever)!! and in trying, it's starting to get pretty chewed up too. I've added penetrating fluid.. then tapped it, then banged on it with a hammer to the screw-driver to try and loosen it, but no luck. Any suggestions for this issue? -

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

Hi Glenn, I have moved the feed dog to 1/2 tooth above the plate at full height. Thanks for that info. -

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

Man, I owe you one for going out of your way to help!!! Here's a video I found of a CW-8 machine (non lubricating or reversing), that I think the user is making adjustments to the stitch length manually but it's in a language I don't understand. See the video starting at 2:35 or so, thru to about the 3:00 minute mark. I certainly could be wrong but.. it's how I'd envision the adjustment procedure to go on my machine. Thoughts? -

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

Sounds good ... I also have the following parts list from the newer Consew version: http://www.consew.com/Files/112347/PartsBooks/287RB-2.pdf Of course if they're the close enough and you're more familiar with the Seiko, then by all means.. let's use yours. So, to recap - top stitches too short in forward (at max adjustment length), and Reverse acting funny (short on top & loops on bottom). Couple other issues I'm noticing [may or may not be related to the main problem]: -after sewing a line of stitches, bringing needle just past the top and lifting the foot - the thread does not put out easily for me to snip them off (I have to rock or sometimes manually reverse the hand wheel to get the work to pull out far enough). -Also, I keep getting the feeling my top thread tension is just a bit too tight despite having the thumb screw/spring loosened quite well. -

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

-

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

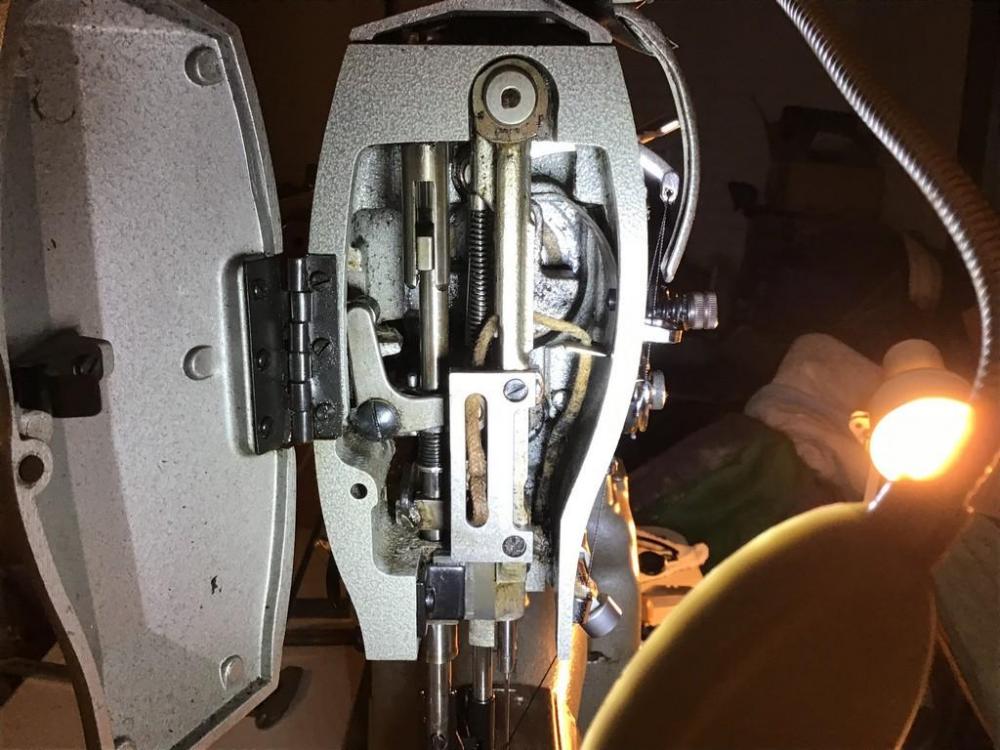

Hi guys... THANKS SO MUCH for y'alls help!! Uwe, you were real close with the Seiko.. the following is a picture of my machine, also a pdf of the newest version of it from consew. http://www.consew.com/Files/112347/PDF/287RB.pdf -

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

Ok shoepatcher touched on a couple items: first, my feed dog come real close to (possibly touches) the front of the plate during a rotation, and the back is a couple millimeters from the back when the FD comes to that side. So I need to adjust that - BUT HOW's IT DONE? Secondly, my feed dog did seem low (as Cowboy Bob pointed out in an earlier post) so I raised it.. maybe too much but my 'adjustment procedures' for a Singer 153Wxxx showed it should be 1.6mm above the plate. Would it being too high cause the looping stitches on the back side of the material (as seen in the above picture)? Here's my feed dog as it sits now: -

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

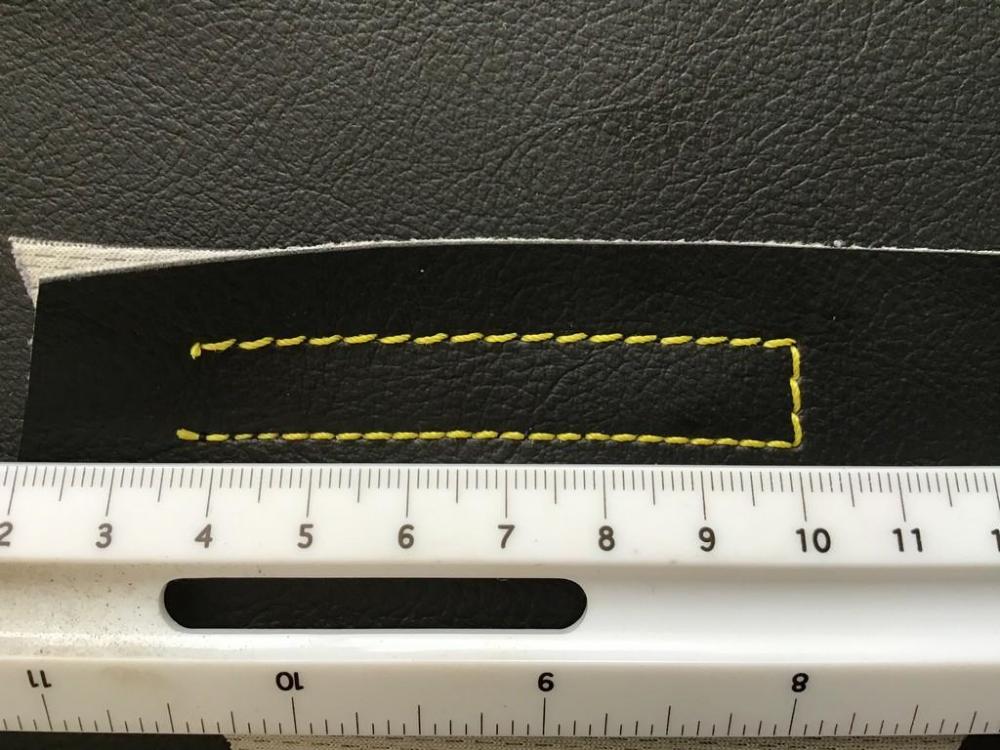

YES - There is definitely a problem with my Reverse ... the stitch length is even shorter than forward, and I'm loosing tension from the top thread (loops on the back side of sewn vinyl). Here's pics of this particular issue (Note: forward stitching = top row, reverse on bottom): BACK SIDE: -

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

Cardboard got me 4mm holes... switched back to the vinyl and now a contrasting yellow 138 thread and it too showed a solid 4mm stitch length at maximum. I can't help but think it's an internal slip of a rod/gear. -

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

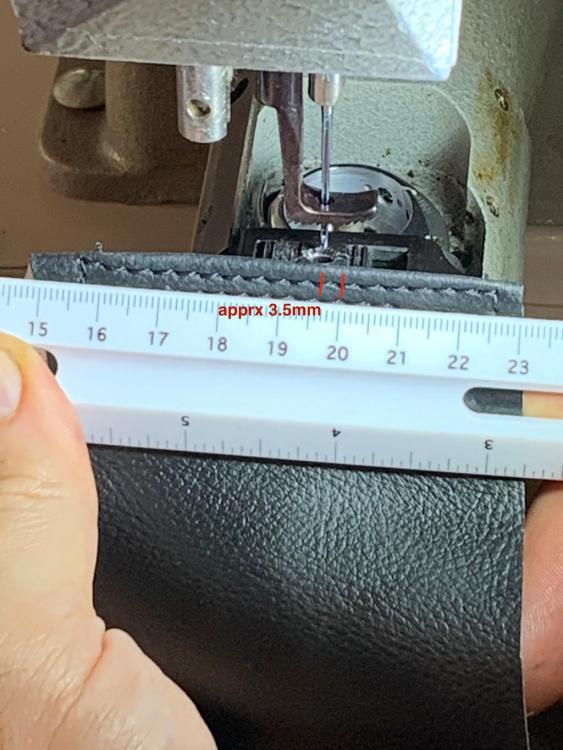

@Uwe Here's a shot of the stitches I'm getting on maximum, I'd say they are 3.5mm (pic actually makes them look better) [I've obviously removed the rear foot for the pics - but if it makes any difference the alternating foot is serated and the other is smooth] & again, size 138 poly thread... surely this machine will do bigger stitches than this?: -

Stitch Length HELP needed Consew 287R

CustomDoug replied to CustomDoug's topic in Leather Sewing Machines

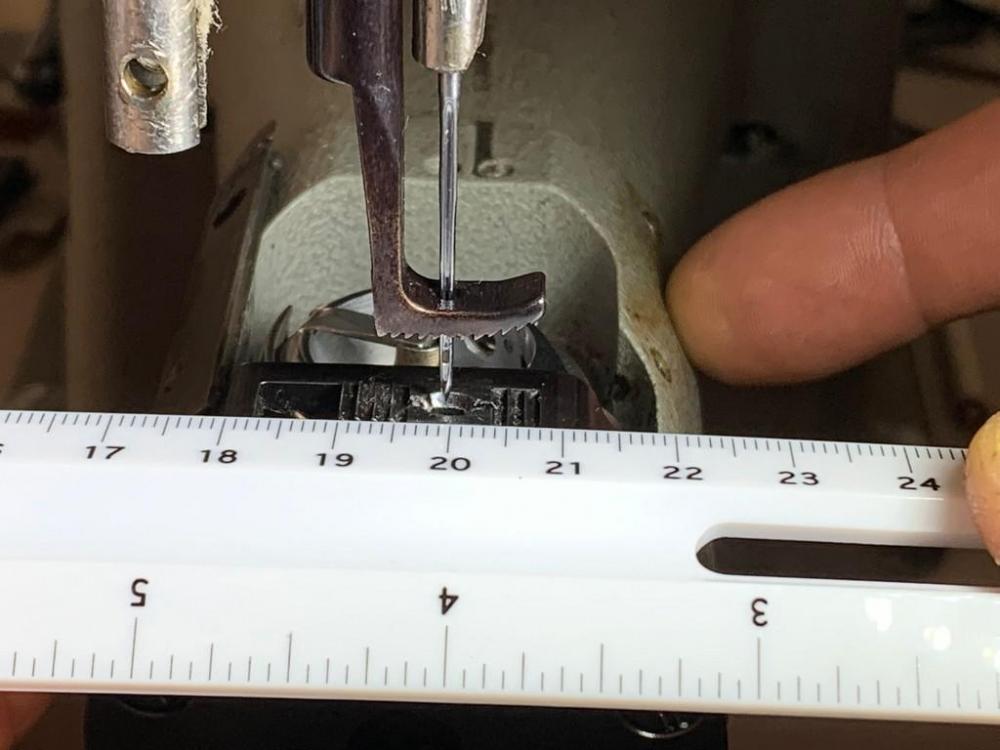

All the way forward: All the way back: Well, close to 6mm, real close to it when tested as you suggest. But it's not translating to the stitch.