GeneH

Members-

Posts

108 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by GeneH

-

Used straight or round knife on a budget - brands?

GeneH replied to GeneH's topic in Leatherwork Conversation

I saw those but had no reference. I like the edge I get sharpening D2 so his looks good. Thanks for the really quick reply! -

Used straight or round knife on a budget - brands?

GeneH replied to GeneH's topic in Leatherwork Conversation

Am I likely to find as good (online) used? The Osborn’s on eBay now (in the $35 shipped) look pitted way more than I would like. But that’s just a small sampling. I can wait a month for the right deal to show. -

I'm on the hunt for a general purpose knife, probably used, that would be a leap from x-acto or utility blades. The limiting factor is (of course) cost as my budget is really thin. Experience with kitchen and outdoor blades seems I get harder, easier to sharpen non-stainless for the price - seems cheap stainless is just .... mushy. I don't know brands to look for, or exactly what shape I should get, but am leaning to a single bevel low angle or a round/head knife (the one with less curve and more pointed tips). (Armitage shows how a low angle blade can cut thin leather, but that's all I know) I don't want to use my wood carving knives again - their really thin and took a beating. Nor do I know how to identify the manufacturing period, if that's a consideration for a particular brand. So - can you folks give some guidance? I really want to keep under $40, no hurry. A nice stiff, thin, hard but not prone to chipping, blade would be awesome. Don't even care if it's dull as snot - sharpening is my zen time anyway.

-

I took a closer look and you can see the round rivet under a square mask. Possible maybe to swap some masks to the other side?

-

Farting around with leather.

GeneH replied to hawgrider's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks good! Is that a tapered welt? -

Black watch strap with red stitching

GeneH replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Wow - having some places to cast, some not - I hadn't realized you had that much variation when stitching your wallets. That makes it even more impressive. Thanks for the details! -

Black watch strap with red stitching

GeneH replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Beautiful stitching - it's a fine piece to use as an example of how stitching can look. I'm really digging the red-on-black. Thanks for the details you posted yesterday, in particular the 4 concise bullets, hardware and reference to Meisi thread. I'll probably order some, particularly because it comes in smaller spools. Back to the bullet points: I have pictures of stitching where I did something similar - now I can use those 4 bullet points to go back and evaluate again what I did. When you mention,"... moderate angels...," and "...heavier angles...," are you referring to how you pull the thread, such as up-forward, down-back (or whichever direction it's supposed to go) to help set the thread slant? -

Is this stitching weakening the belt loop?

GeneH replied to GeneH's topic in Leatherwork Conversation

Thank you both for the compliment. Seriously could not have done this without the wonderful help on this site. -

Farting around with leather.

GeneH replied to hawgrider's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Good to know the holes can close that well. The key for alignment that I need is the leather has to be laying flat, and I can look almost horizontally at the chisel so I can estimate a vertical at 90 deg from the table and leather. I can do this with the welt in place on one half, so I can punch most of the way through 2 - 8 oz thicknesses. I place a piece, same thickness as the welt, under the unsupported part so it is level, and even placed a weight to help. Everything has to be prepped so I can get a line on the backside to help. Then after folding and glueing the other side it goes into the stitching pony. That gives me a guide hole I can slide, very lightly, my diamond awl into. Any sensation of cutting until I know I’m far enough, or if I see the leather puckering out of alignment just before exit, I pull back a little and correct. It’s really slow but the results are worth it until I find a better way. I tried punching the back but that didn’t give good stitching on practice runs. Alignment with the front, even with registration holes aligned with needles was off. -

Farting around with leather.

GeneH replied to hawgrider's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Hawgrinder your sheaths look really good. What drew me to chime in though was your comment, "trying to come up with a method that narrows the risk of trashing the piece if I land a the holes in the wrong spot." I looked closely at the stitched ones and they look really even. When I looked at the not-yet-stitched, very closely, I could see holes pretty large and out of alignment. Consider my experience has been 4 pieces stitched so far, but here is what I've learned from the good folks here. Oh-this will ring true for your as a hunter: aim small, miss small. (I don't know who to credit that saying to) Make the guide lines for your chisel very fine, and the chisel point should not be wider than than very fine line. You'll catch the tinesy mis-alignment right away. I'm stuck with a 2 prong diamond chisel, but if I pay attention, the alignment is really really good. I first just press marks with the chisel points for the whole length, then go back again and punch the initial holes in the first layer, and not using an existing hole to align my chisel. Make sense? I punch 2 holes at a time, using marks only, not a just-punched hole. That way I land exactly on that tiny mark. But I have to be very careful with each time I set the punch down. the finished holes actually work well to guide my diamond awl through the other layers (if I use a light hand) so the backside looks pretty good - not perfect, but acceptable as a backside. -

Is this stitching weakening the belt loop?

GeneH replied to GeneH's topic in Leatherwork Conversation

Thanks RockyA! I do have to say I’m pleased with the stitching by the snaps. I had to start at each side of the snap and work round towards the back to keep the symmetry. Good learning piece. -

Is this stitching weakening the belt loop?

GeneH replied to GeneH's topic in Leatherwork Conversation

Calling this one done, except for conditioner especially inside the belt loop. I am not pleased with any of the edge finishing. The mask came out nice, and I don't know why this piece didn't come out as clean. The hatchet hangs very nicely with its handle tilting slightly behind and inward out of the way. I'm satisfied with the stitching considering that's the second article stitched, and the number of times I pulled a few stitches back to start over. Mistakes and errors: The snaps are covering up permanent marker near the top, necessitating splitting the stitching into left and right as I did not want to go under a snap. Now I know how to stitch starting left handed and starting right handed and make both look the same. Win. The picture of the bottom shows misalignment of the strap, partially because it was punched with that end destined to be the top. That bottom was supposed to be the funneled top but I must have had wax on a burnisher because it would not take dye. The black dyed top was supposed to be the bottom because it wasn't as clean. I accidently rounded and slanted the loop between the belt strap so that looks funky. -

Is this stitching weakening the belt loop?

GeneH replied to GeneH's topic in Leatherwork Conversation

Nope, no clicker press. I used my wood carving knives because of budget restrictions, but that was *H* on the thin blades. No production goals, these hobby one-offs. However, the whole process should go smoothly without so much time just putzing and struggling to make the pieces fit and look right. -

If I may, I'll jump back to my hatchech belt loop thread as an example of really excellent collaboration of ideas and opinions that I'm grateful for. Another 2 good opinions popped up resulting in a redesign of the belt loop. I'm now encouraged instead of discouraged from that first attempt. This is what I strive for in my workplace, home, and these forums I haunt. The decisions are mine, and I can make better-fitting decisions when I have more information, both good and not-so-good.

-

There are reasons every village has to have one, and it's our responsibility to help that person recognize there is a village short one person... LOL. And "all I want to do is have some fun." That's exactly my sentiment. Along the way I hope I can make someone's else a little easier and a little cheerier.

-

Is this stitching weakening the belt loop?

GeneH replied to GeneH's topic in Leatherwork Conversation

As of last night I had decided to not make another one. Now I can't wait to get started on the next. -

Is this stitching weakening the belt loop?

GeneH replied to GeneH's topic in Leatherwork Conversation

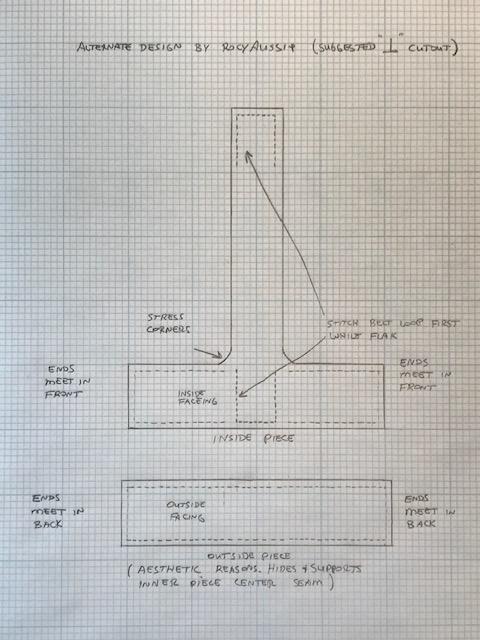

Yep, that's a better idea. Cleaner design, I don't need rivets, and I bet I saves 2/3 of the cutting/fitting/assembly time. I pretty much finished the original one last night (pictures forthcoming later this weekend) and getting that strap bolted to the hatchet loops was a battle of wills. Inanimate cowhide almost won. That first build has too many compromises (IMO) the way the strap is secured. This, as you suggested will be my next one. I wasn't going to even try another like I did. This one has "U" shaped stitching on the strap which I think might be the strongest, though probably not necessary. No vertical stitching on the wraps because that's outside my temperament level and again not needed for a hatchet. -

Is this stitching weakening the belt loop?

GeneH replied to GeneH's topic in Leatherwork Conversation

Chrisash: That's a really good point: break-away safety. I thought about covering the blade only. I've slipped on a wet leafy steep slope more than once. I may have gotten lucky using this style hanger. Hopefully on the initial slide the handle catches and the hatchet slides right out without smacking any ribs on the way. I tried to make the accompanying mask stout enough, though the snaps holding it might come loose in a fall and expose the edge. I'll give this more thought as I go forward. The one safety issue I am concerned about is my own inattention and putting the hatchet w/o the mask, "just for a moment," in the hanger and slicing my arm the next moment. Inherent design weakness. -

I *REALLY* have to get in on this conversation now, because that was my post! (Sorry for the long quote, but it's relevant) Seems none of my family gets the irony when I say, "You're not going to win this argument with me because I'm convinced I'm right." LOL You mentioned, "advice would have been counter to some that had already posted." That's not always counter productive - the (IMO) value is being able to articulate *why*. Advice like, "huh.works for me" is somewhat useless as everyone (including yourself) in this discussion already knows. "Under these _________ conditions, failure is probably not going to be a problem." or "Well, if you try to hang from a tree, might think twice, otherwise, NP." Your opinion of empirical/historical evidence and testing is valid, but may not apply here. Let me emphasise, "may." Won't know without being said, right? I received varying and clear options, opinions, suggestions, and appreciated every one of them, yours no less than any. Good thread. Thanks for the invite, H.

-

Is this stitching weakening the belt loop?

GeneH replied to GeneH's topic in Leatherwork Conversation

Agreed on both points H. Screws or no screws is an aesthetic roll of the dice for me. I left them off the hatchet mask for just that reason. -

Is this stitching weakening the belt loop?

GeneH replied to GeneH's topic in Leatherwork Conversation

This is for carrying a 1- 1/4 lb hatchet. I would have liked to go with only stitching just to say that I can, and even though I won't be using it for bungee jumping, I do what very solid, non-floppy, construction. A knotted paracord or brass ring would have sufficed, but that's so .... pedestrian. :-) I cut the the strap off at the perforations last night and have test fit the chicago screws, leaving room for the vertical stitches that you have marked clearly on the diagram (thank you for that effort) Rockoboy thanks for validating using shortened needles. I didn't know if I was going sideways or not. I'm surprised how firm this leather is at this thickness, I bet the belt loop never loosens up using just screws, even without glue. However ... I'll glue this one and might even use it to practice the vertical stitching before I go on to the next. Pictures in a couple days.... -

Best Glue For Leather To Leather, And Leather To Fabric

GeneH replied to CCPhotog's topic in How Do I Do That?

Thanks Dwight! -

Best Glue For Leather To Leather, And Leather To Fabric

GeneH replied to CCPhotog's topic in How Do I Do That?

Part of my question was comparisons between Weldwood, Barge, and E6000, but I wasn't clear on that. Ooops. Thanks Dwight. Yep, first piece I didn't do right, and now it's going to be up to the stitching. But there isn't much stress so should be fine - after that I tried scuffing the hair side and that worked. I was a little surprised that it was "slick?" enough (is that the right word?) or impervious enough for the Weldwood to not adhere. Says a lot for leather - pretty good stuff. I am just figuring out the "pleather" aspect of multiple layers - just learning how well it works. Glad you validated that. Regarding soaking and possibly oil - I'm thinking outdoors in the woods, dressing a game animal, rain, dunk in the lake (ooops) or spilling fuel or something on a sheath. Clumsy mistakes like that. -

Is this stitching weakening the belt loop?

GeneH replied to GeneH's topic in Leatherwork Conversation

Sounds good. It will look better than imperfect stitching. I might stitch the bottom. Later I can do some practice pieces when I find the right bent and curved needles. Struck out at a local Joann fabrics. I will post pictures in the critique area when done.