Kcinnick

-

Posts

148 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by Kcinnick

-

-

Cowboy 4500

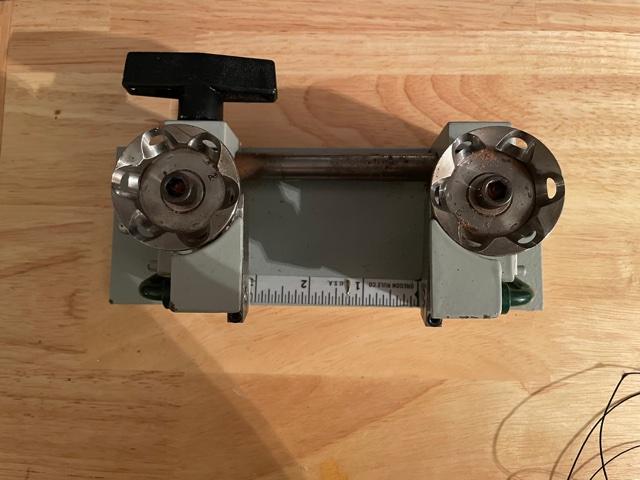

Master tools hand operated strap cutter

Bluegrass E-Z edge "economy" edger

Heritage foot press with staple attachment

$4000 picked up in Baton Rouge, Louisiana. I also have a few hides, not sure exactly what, most of the leather I bought was Hermann Oak but I think a hide or two might be just generic weaver "Bull hide".

The only defects I noticed on anything is that the motor housing on the Cowboy is dented, it is purely cosmetic and I am 99% sure that is how it came when I bought it new. The "fingers" that separate the straps on the strap cutter have mild surface rust, I suspect this is because I kept the metal clean to not contaminate the leather and then it sat up (climate controlled) for a while without use, should be an easy clean up. I would highly advise taking the sewing machine off the stand for transport unless you rent a truck with a lift gate to pick it up.

-

I have always used double layer HO leather. I didn't like horse hide for holsters or belts when I tried it.

-

This is the first time I went to order from Weaver since they had started online ordering. I was looking for the place to put my order in and a online shop came up. Is there a way to link your wholesale account with the online shopping or did they move the place where you order for wholesale?

-

Medicine balls take some abuse, I was given some directions by someone on how to build a dodecahedron ball, so I will try it out. I might use some belly or I might get some pleather or some sort of vynl. I was given a pattern on how to stitch the polygons to have minimal times you had to stitch with the seems curved, well verbal directions, I will have to see how it all lays out.

-

See, I know the basic Idea. What would help is what order to go in, how deep to put the stitch lines in and what sise pattern makes each sized ball. I can make a polygon pattern with basic geomatry, I just need to know how large to make them and how exactly to stitch them and in what order.

-

Does anyone know where I can find a pattern for a medicine ball? I have a request for a set, with potential to sell many more. I basically know what to do, I just don't know what size to cut the shapes to get the proper size, and I am not sure when they say to double stitch if it means to throw my cowboy in reverse and stitch again or to have two rows of stitching.

-

I put the scars on the outside! People love them. If a solid piece has a minor wrinkle I will use it to line the inside, but 99% of the time I am using a piece as good or technically better on the inside. Mostly I choose straps based on length rather than looks, they all look good once assembled, especially with well placed "defects"

-

I make belts in batches of 30 or so. It saves tons of time as I am able to fill my orders and have belts sitting around to fill orders with. I leave sim just glued up, not cut to length, stiched or punched yet. I couldn't imagine doing one at a time of working without a foot press. It punches perfect holes, saves a ton of time stapling keepers instead of stitching and makes setting snaps and rivets on holsters a breeze.

-

The Weaver and Tandy are the exact same magnet sets.

-

I am making a small Springfield order also, I can check theirs out. I usually only make stuff to order, but I have an outlet to sell my extras at that already buys bullets we make.

-

I find two layers of 7/8 Hermann oak good for belts, I have a lot I can use I was just worried about wrinkles on the inside layer. I glue my belts with the leather curved to prevent wrinkles on the inside, I would imagine with a dog collar you would have to have dang near a circle.

-

I have some 4/5 I can use.

Pretty much I just need two rectangles and magnets glued and stitched?

Are the weaver magnets GTG?

-

I have been trying to get wild Louisiana Aligator for about a year now, and I found the best way to do it. BUY the dang gator straight from the hunter. Anyway, I have secured a few hides from this years season and I need to know where to send them. I know there is a place in Lafayette LA that tans them, but I want to send them to the best place I can.

I am getting a hometown discount and did some bartering to get the hides, but I have to pay for tanning, any suggestions would be great. Next step is securing my own tags.

-

I am doing a craft show to benefit down syndrome soon, and I wanted to have more items than my usual double layer belts and holsters. I have never done a show, and I am doing this to help out a friend. I have lots of quality Herman Oak Leather scraps that would be great for just basic money clips and Credit card holders.

What is the correct weight leather to line the inside to hold the magnets and have them work properly. I plan to use 7-10oz Herman Oak leather on the outside, a variety of tooling and bridle leathers. I was planning on ordering the magnets from weaver, unless someone had a better place to get magnets or knew of a better magnet.

I am also going to add some things I don't normally make, pet collars, leashes, single layer belts. Not really doing anthing fancy, just well put together made in the USA pieces.

-

I am doing a craft show benefit for down syndrome for a friend that has a child with down syndrome. She has orgainized this craft show as a fundraiser, so I want to do what I can to contribute. I mostly make double layer belts and holsters, and have never really dabbled in any other leatherwork. I wanted to have more things to offer, not that I am concerned about profiting at the show, just really contributing. I have never done a show, I get enough orders through word of mouth and email/internet forums to keep myself busy to not justify spending the time and money it takes to invest in a show.

Anyway, I was concerned about using two pieces of thick leather for the collars like I do with my belts, mainly since I feel the inside layer will wrinkle with such a severe bend. Anyway, I have lots of 7oz cutoffs that I haven't cut into holster loops or belt keepers and I planned to use that as the outer part of the collars. I was considering lining the inside with deerskin or a lighter weight leather, but wasn't quite sure what would be appropriate.

I don't plan on doing any stamping or carving, just basic solid working collars and leads, maybe a some conchos and decorative spots. I have the weaver heritage foot press and I am considering getting the spot setter and guide to make some quick even spaced designs.

I know the basic construction techniques, I just need some suggestions on proper sizes, weights and hardware. I will probably place an order with Weaver this week. I also plan on doing some basic magnetic money clips and some single layer belts, to have something less expensive at the show. I don't plan on making anything I can't sell, but I want some items that will appeal to more than the normal gun enthusiest crowd I normally do business with.

-

Runs of Belts I settled on about 2 stitches per second. It is double layer Hermann Oak 7oz veg tanned leather, I hand wheel the English Point, it is faster than feathering the pedal and gives me very accurate, nice looking points. I run 12-15 at a time 2-3 times a week on belt weeks. On Holsters, I go really slow, like a stitch every 1/2 second, only because stitching is about 5% of the time I spend with a holster and is 100% of the time the step I mess one up!

I should clarify that when I sew fast on a 441, it is usually into about 1/8 to 3/16 inch of medium temper chrome tanned leather. Most of the fast jobs are large production runs of rifle slings and guitar straps (two parts each). The #138 thread is pre-lubricated and the needle is a Schmetz #23 S point. It is not unusual for me to have to sew 2 to 4 dozen for delivery the same day.

On these large runs I usually have a spare bobbin loading in the bobbin winder as I sew. Downtime to reload is minimized this way.

It is not unusual to see smoke coming from the needle as I sew these straps. I have never burned or broken the lubricated thread from speed sewing. I have broken it when I don't get it to release the tension disks all the way! I hate having to pull the top thread out of the take-up lever by hand, so I balance the tensions to allow the top disks to fully separate when the floor pedal is depressed.

When I am sewing saddle bags, cases, holsters, or hand stamped straps, I slow down to about 3 or 4 stitches per second. Very thick projects are usually done at 1 or 2 stitches per second, but they aren't for production runs. If I have to do a production run into thick leather, I use my Union Lockstitch machine, flat out at 800 RPM.

Art;

I'd like to learn more about that machine. Is it still in production?

-

The way I have always looked at it is this way. First, become effective. Whatever you are doing do it right and with as much perfection as you can. When this is accomplished go for efficiency, kick it up a notch. Effective is quality and efficiency is speed. Junk fast is still junk. Outstanding slow is still outstanding. Outstanding, fast is more money. Simple................

Jon

I look at it like USPSA shooting. I started out going for points, now I am trying to keep my points and increase my speed.

Same thing with the belts, I don't turn out junk. I make basic Hermann Oak double layer gun belts, and its pretty straight forward til you get to the tip, and thanks to the great guys here I can turn out Great Looking tips every time!

My belts are even better now.

-

That's easy: 800 RPM at the machine.That equals about 13 stitches per second. Keep it very well oiled if you sew at that speed on a regular basis.

The same speed applies to the Cowboy 3500 and 5500, Cobra Class 3 and 4, and all other brands of 441 machines.

Due to vibration issues, I would limit the top speed to 10 stitches per second on the big stitchers, or 600 RPM at the machine.

Thanks, I keep it well oiled at any speed!

I will have to figure out what the # settings translate into RPM's! But I guess I am good to crank it up a few, I don't want to get anywhere near 13 inches per second.

-

I have the same machine. You should be able to sew 2 - 3 stitches per second easily, especially on a belt. I think I stitch faster than that on holsters (not around corners, but on straight sections). You just need to experiment with the speed settings and find what you are comfortable with. We can't tell you what speed setting to run. Just get some scrap leather and experiment.

I can tell my limits, I just want to know the machines limits!

-

Kcinnick,

You'll know you are going too fast if you screw something up. The machine will stitch just fine at a high speed, you just won't be able to control the placement of the stitches very well. If you have an edge guide, that will help. Speed isn't everything. I learned that the hard way. Just turn up the speed until you get to a point where you don't feel like you are in control. If you go too fast, and ruin a belt, you'll have to remake it. Those few seconds you save by going as fast as possible will be lost 100 fold when you have to remake that belt.

What is great about the motor is the speed settings. I can feather the peddle to get different speeds, I can set the start speed at whatever I want, and the top speed. I have the slow setting, must be 1/2 a stitch a second, it is where I do the point at that speed, heck, I hand wheel the last stitch at the point. I am not looking to go super fast, but, would 2-3 stitches per second be reasonable? I have an edge guide, it works amazingly well, but I think i want a drop down style one for more versatility. The machine came set up at 18, I didn't know if there was a reason for it or not, but I assume it goes to 100... When I sew holsters I drop it down to 6 since 1/2 the work is free hand, but I just want to speed up belt straight lines.

Nick

-

Are there signs to look for that I am going too fast? I just want to cut down my sewing times, I have cut a lot of time out of my process with using a bluegrass edger, a roller to apply glue, making templates for all my holes and the areas of the belt I don't glue. I want to be as hand made as possible, but speed things up. I have a full time job and currently sell EVERYTHING I make. Within minutes of posting an unpaid order for sale, its GONE. I had a glock holster a guy backed out on last 15 seconds! I am just trying to make some more $$$ so I might be able to make this a full time gig, and to get some more equipment.

Nick

-

What are you stitching?

And what's your hurry?

Gun belts. I am running 15 or so a week and will be expanding with a couple of stores stocking my products.

-

I currently have my Cowboy 4500 set at 18 for two layers of 7oz leather, but I feel the machine can go faster, and I know I can go faster now. How fast can I crank the machine up?

It has the newer digital motor on it, not the knobs.

-

Hey Big Poppa Leather,

I have 50 Mechanic's Buckles being blanked out as I write this. 300 series stainless steel; 1" wide X 2.5" long. 2 prongs. Estimated cost is about $4.50Ea. Shipping is actual cost, your method as preferred. I'd like a minimum order of 5, if possible. Will have photos (hopefully) by end of this week. Sound OK?

Sorry about the delays. Much illness issues. CAMPCHAIR

See below - Campchair

Do you have any more, I could use a few...

Cowboy 4500, Master tools hand operated strap cutter, EZ edge "economy" edger, Heritage foot press

in Old/Sold

Posted

Just an update. Someone is interested in just the press and edger if someone has interest in the Sewing machine and Strap cutter. Also, The sewing machine came with the kit with extra feet, table, edge guide etc. that adds $400-$500 to the cost of the base machine.