-

Posts

1,311 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Rawhide

-

...here are three belts just completed. I designed these for some young girls back in the eighties (made then in plain tan leather).... seems they have come back into fashion in some parts of this world. I had sterling silver rings made...stainless steel didn't seem right with the black alligator.. Peter

-

Here's the word from Peter ...I should have mentioned that these are inlays for boot tops. They will be quite striking, as the tops are to be black kangaroo. They are colored with orange spirit dye...a very tedious operation. Peter

-

He didn't say, but I'll ask...he may not want to say until it's finished.

-

...these carvings required the making of several very small backgrounders....based upon the A99's. Peter www.petermain.com

-

Sounds like you need an awl haft with a chuck. These hafts come with a wrench that allows you to tighten the chuck jaws on the blade. I've attached a picture of one

-

A point of clarification. A scratch awl is not the same as a diamond awl. The scratch all is completely round and tapers to a point. The diamond awl is specifically for stitching. The awl pushes the material to the side and it will close some, not completely, but it will close....which is one reason the 'proper' technique is to pierce & stitch one hole at a time. the strength of the different holes has been debated to death, however my argument would not be the hole itself, but where it ends up on the back of the project. I can't control a drill like I can an awl. I tried the drill, but found that my holes were all over the place on the back side and my stitches looked like connect the dots. In this case, for me at least, the old fashioned method works best, hands down. I don't even use a four prong punch anymore on thin leather.

-

What happened is that all the outflux of people went to neighboring citites and towns and supply and demand dictated a localized inflation. Most people couldn't afford to maintain multiple residences and had to forgo their properties in New Orleans. Those who bought these inflated the prices, along with the insurance rates skyrocketing, the real estate has gone through the roof. Plus, not every area has been refurbished, so that leave the refurbed area 'desireable' and inflates the prices even more.

-

There have been a slow influx of folks moving back to N.O., but the problem is that the cost of living has skyrocketed since the hurricane, that most can't afford to return. I'm originally from the state of Louisiana, and know serveral families that have returned, and several that vow to never set foot back.

-

see this thread

-

For thicker leather, it's almost imperitive that you groove the folds. I even take a french edger after that and put one leg in the groove and hold it at about a 45 deg angle and take off some of the side on both sides of the groove.

-

I'm a big supporter of hand stitching and I use an awl with two needles to do it. The 'proper' way is described in Al Stohlman's book, the Art of Handsewing Leather. However, decent instruction can be found on the interweb. Using a dremel is a fast way to do it, but the results of the holes on the back side of the project will be unpredictable. Yes a hole can be too big or too small. I have two diamond shaped awls that I use regularly, along with a set of overstitch wheels. The overstitch wheels layout the locations for the holes. there are several sizes. for a heavy weight leather, 8 oz and up, I use 5, 6, or 7 stitches per inch (spi), for medium leather, 4 to 6 oz, I use 8 or 9 spi, and for light weight leather, I use 10, 11, 12 etc, spi. For holsters, you're probably looking at 6 spi, and a four prong stitching chisel is not going to go through that thickness of leather stack (plus it makes the holes too big). you'll need a sharp awl, and the overstitch wheel. Good luck!

-

I have 8 ft lights in my workshop. the bulbs I use are 5000K bulbs from Home Depot. 5000 and 5500 K are the closest to simulate daylight.

-

I think he's got one of those 'easy buttons'

-

Jim Linnell In Baltimore

Rawhide replied to kimberangel's topic in Special Events, Contests and Classes

Show off... Jim is a fantastic indiviual and is a joy to learn from. -

Karl this is what I use... It's called the Ben Cox formula. It's 1-1/2 cups water, 1/2 cup lexol conditioner, 1 tablespoon of baby shampoo, and I put in 1 tablespoon of listerine for mold prevention. You can scale everything up to make a larger batch. It seems to keep well as long as you shake well before using it. I pour some out in a small plastic tub (tupperware style) and apply it with a sponge. I think it makes the burnishing of bevels a lot better for contrast.

-

I'm pretty sure they're dyed. He RARELY uses paint. The white color may be a wash of acrylic, but I'm willing to bet that's about it.

-

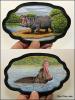

Some belts for a quiet time...

Rawhide replied to Rawhide's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Peter is an extraordinary gentleman from Austrailia who started out as a graphics designer. He began playing with leather as a medium in the seventies. He's written several works on Al & Ann Stohlman, as well as a couple of his own books. He currently resides in the US. If you ever have a chance to meet him or take a class, be sure and do so. He's one of a kind. -

Holster...by Peter Main

Rawhide replied to Rawhide's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Here's Peter's response.... In answer to the feather tooling. On molding work, it would be most unwise to do any tooling first where the leather must form around an object....much distortion and opening of cuts will occur....also any decorative work will flatten a little. This piece was rather simple...I allowed the leather to dry over a day or so....then just moistened the area where the feather was to be. The feather was then traced, the outline cut with a swivel knife, and detailed only with 'that' modeling tool. I pushed (no mallet use ) a pointed beveler around the feathers for detail, then added a little hair-blade work. Spirit dyes were used for coloring, with just a touch of diluted (to avoid an opaque look) white acrylic. -

Hmmm, I've never had any problems with the left hand twist. Maybe I've just figured a way around it without knowing it. I've purchased 3 cord and 5 cord already, and don't really see myself running out in a LOOOOONG while, so until I use it up, I'll probably stick with what I've got. If I run into someone that has some right hand twist, I may see if I can bum a couple of feet to compare. Thanks for the knowledge John.

-

Holster...by Peter Main

Rawhide replied to Rawhide's topic in Gun Holsters, Rifle Slings and Knife Sheathes

John, I feel your hate!! Just when you think you've got some consistency in creating good work, Peter comes along and knocks me down a few stories while adding a few stories, and I have to get back on the stairs and start climbing again. -

Al Stohlman indeed. I've modified several tools to work the way I want them to.

-

Some belts for a quiet time...

Rawhide replied to Rawhide's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I believe it's just a thin leather liner that's tooled dyed and sewn on. Peter's dying skills are so tremendous that he can make illusions where there are none. -

Holster...by Peter Main

Rawhide replied to Rawhide's topic in Gun Holsters, Rifle Slings and Knife Sheathes

the first (lower left) picture is the male part of the snap and the female part isn't installed yet. the second picture has the female part installed, but the button is covered with leather.